Imagine yourself sitting in your car, driving to work in the rush traffic. Around you, you can see a lot of buses, some are full, some are half full, and half of the buses are nearly empty. When you decide you want to transition to public transport, and take the bus yourself, the ticket app tells you that there are no available seats, all buses are full. Not just today, but in all foreseeable future. Still, you see the empty buses driving around all day long.

This may sound like pure fiction, but this is how the electricity grid works today. When someone wants to connect to the electricity grid, perhaps to transition from natural gas to electricity in an industrial process, they are in many cases told that the grid is full for the next decade. In reality, the grid may still have a lot of available capacity most of the year. And even during peak hours, there is excess capacity due to reliability precautions. In the metaphor of buses, this is represented by the empty buses driving around, “just in case the bus in front has an engine failure”. In the FME CINELDI, there is an ongoing pilot to investigate the actual capacity in the grid.

All these precautions combined with the uncertainty of when consumers in the area actually use electricity are an obstacle to rapid electrification and decarbonization of the Norwegian industry. There are already many stories presented where industries want to decarbonize their processes, but do not get access to the required electricity, such as in Kronos Titan in Fredrikstad, or in Grenland.

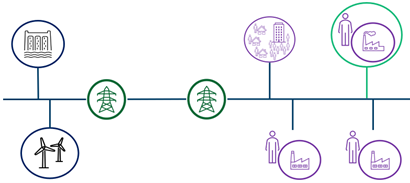

But what if it is possible to move the electric consumption to hours of low demand? In the figure below, the grid limitation could be either in the local grid, or somewhere in the transmission grid between where the power is produced and where it is consumed.

If the consumers on the right side could agree to reduce their load during peak hours, it could be possible to add more consumption to the existing grid, rather than building more power transmission lines. The grid operator does not know the load pattern of the existing or new consumers, but if the grid operator knows that they will move their consumption if there is a critical situation, they can allow more consumption into the existing grid.

In Norway, the sectors industry and mining accounted for 35 % of all energy consumption in 2021, and more than 40 % of all electricity consumption. NVE has estimated an increase in industrial electricity demand by around 30 TWh until 2040. A lot of the new electricity demand is related to decarbonization of existing processes, which is investigated in detail in FME HighEFF, and is required to reach the Norwegian climate targets. A full electrification will require smarter and more efficient use of electricity, not only in households, but also in industrial demand. The flexibility of industrial demand is in general subject to less research activity, but is now investigated among other places in the project Flex4Fact where industrial flexibility for increased renewable electricity integration in the electricity grid is the focus.

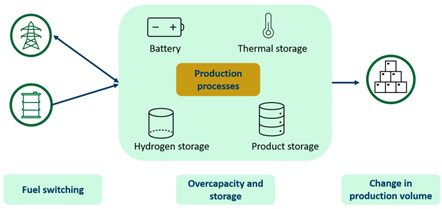

Industrial processes are generally more sensitive to operational changes, and many industrial actors are sceptical to flexible operation, as it will require changes in process operation, and may also be strictly limited by process stability. These processes may have been fine-tuned over decades, operating in marginal competition in a market. In the above figure, some options for achieving flexibility in an existing production process are presented. The solution will be different for each industrial process, but in nearly every production process there is some potential for flexibility, small or large, known or unknown.

Flexible consumption is investigated in several research projects, such as CINELDI, or FINE, and is in particular gaining attention in residential electricity consumption, such as moving water heater or EV charging from day to night hours. I am currently doing a PhD where I investigate the potential for industrial flexibility in Norway, and to what extent this may enable a faster transition to a decarbonized future.

To really unleash the potential of industrial flexibility, incentives, motivation and focus from policy makers and grid operators is required. Instead of building new grid, utilizing flexibility in industrial processes could be a cheaper and faster way of integrating variable power production, but this comes with a cost, which is not necessarily cost-efficient for the industrial actors themselves.

0 comments on “Increasing the pace of decarbonization with industrial flexibility”