What are the environmental impacts of using cold flow technology to transport hydrocarbons? In this article, I will discuss this question based on research from my PhD project.

A bit of background

The latest OG21 strategy document has outlined that after 2030, the production of Norwegian offshore oil and gas fields will increasingly be dominated by new fields. Due to fewer large oil and gas discoveries, attention has turned to smaller, less economically viable discoveries. Cost-efficient development of most of those resource would require tiebacks and utilisation of already established infrastructure.

A tieback is a connection between a satellite field and the processing facility of another field. Future marginal subsea tieback developments may add up to 4 bnboe (billion NOK barrel oil equivalent) from breakeven prices of 50-90 USD/bbl with current solutions. Besides reducing costs, a tieback will also have the potential to reduce CO2 emissions and carbon footprint by extending the lifetime of production infrastructure and reducing the number of required facilities. Furthermore, a tieback will increase utilisation of a facility after plateau production of the main field. This, in turn, will lead to higher overall process efficiency.

However, transporting the produced reservoir streams over very long distances on irregular terrain and with cold ambient temperatures poses flow assurance challenges. Conditions of high pressure and low temperature can cause the formation of hydrate particles that can lead to increased pressure drop or plugging of flowlines. This can in turn hinder optimal extraction of hydrocarbons, or cause equipment malfunction.

Traditional measures to address hydrate formation involve chemical-based technologies, costly thermal insulation, or energy intensive pipeline heating. All these alternatives implicate environmental hazards or rather high CO2 emissions. This is contrary to LowEmission’s target, which aims at decreasing the offshore environmental footprint. The so-called Cold Flow technology is an upcoming alternative which offers both less costs, footprint and emissions during operation. The Cold Flow concept enables the flow of hydrocarbon production fluids at thermodynamic equilibrium in uninsulated pipelines, without the help of chemical modifiers, active or passive heating, or heat-retention schemes.

The Cold Flow Technology

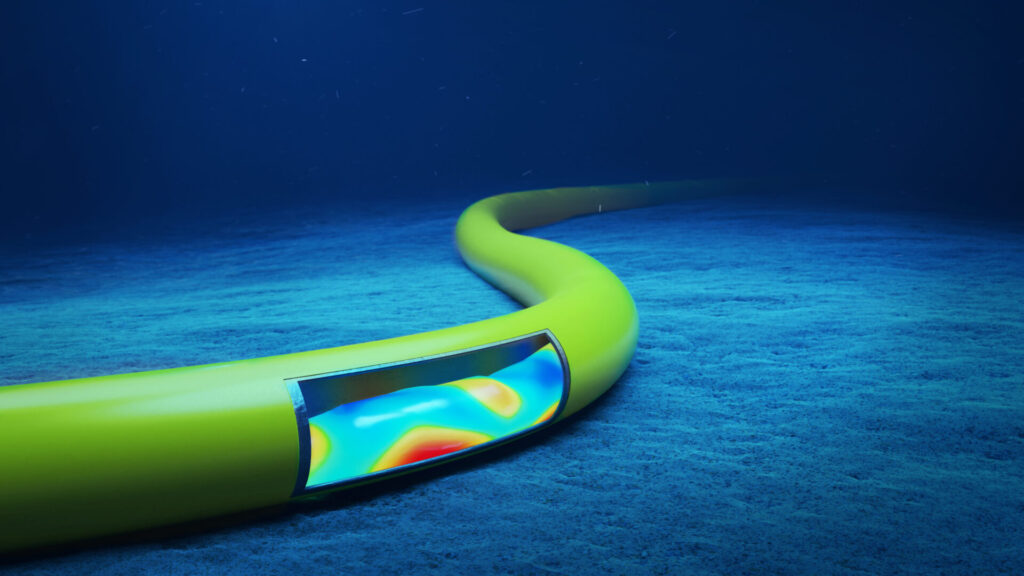

In the Cold Flow concept, hydrate particles are induced in a controlled manner in a dedicated reactor-cooler unit. These so-called dry-hydrate particles will form a stable liquid slurry that can easily be transported and does not agglomerate and plug the pipe downstream of the cooler. It can be defined as a flow of non-adhesive and non-cohesive hydrate particles dispersed in the production fluids.

As part of my PhD research, we performed a case study to investigate the concept’s limitations and to quantify the environmental performance of Cold Flow and compare with traditional field development options. The case was developed with input from industry partners and comprises of an oil field in the northern region that might be produced with a local dedicated FPSO (Floating production, storage and offloading unit) or a 100 km tieback solution to the closest suitable existing offshore processing facility. Cold Flow as well as different heating and insulation options were considered as hydrate prevention technologies for the tieback solution. Also, two different reservoir recovery methods were considered, namely gas injection and water injection. A realistic model of the subsea system and flowlines was created in the commercial dynamic flow simulator LedaFlow to study the fields flow performance and concept feasibility during the lifetime of the project.

Carbon footprint, energy consumption, and related CO2 emissions were estimated and compared for all concepts. The carbon footprint estimates were based on the main components’ weight and a carbon emission factor, assuming steel as main material. Details regarding the emission factor and estimating the weight of construction can be found in our previous works. The power consumption during operation was based on simplified models for the main processing units covering pumps, compressors, heating, etc. Results were translated into emissions assuming an emission factor of 5000 tonnes CO2/MW*year when gas turbines are used for power generation. The detailed procedure of calculating the energy consumptions of the main contributors for each case is also presented in our paper to be published at the 41st International Conference on Ocean, Offshore and Arctic Engineering (OMAE 2022).

Results

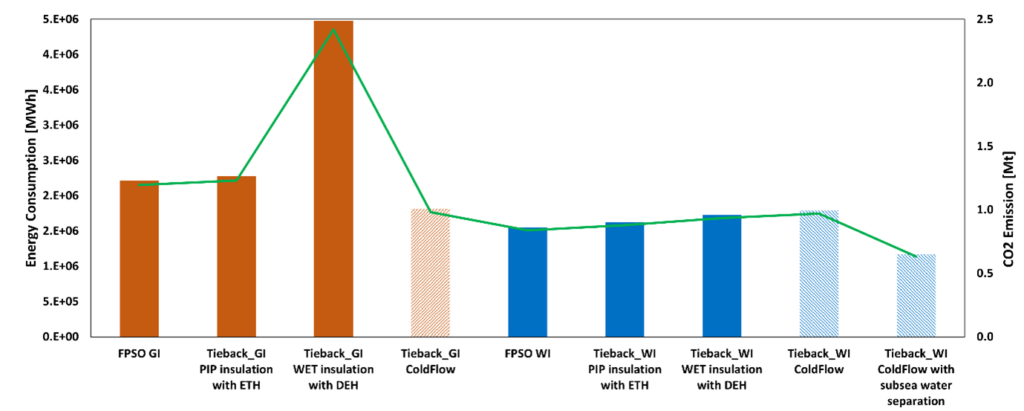

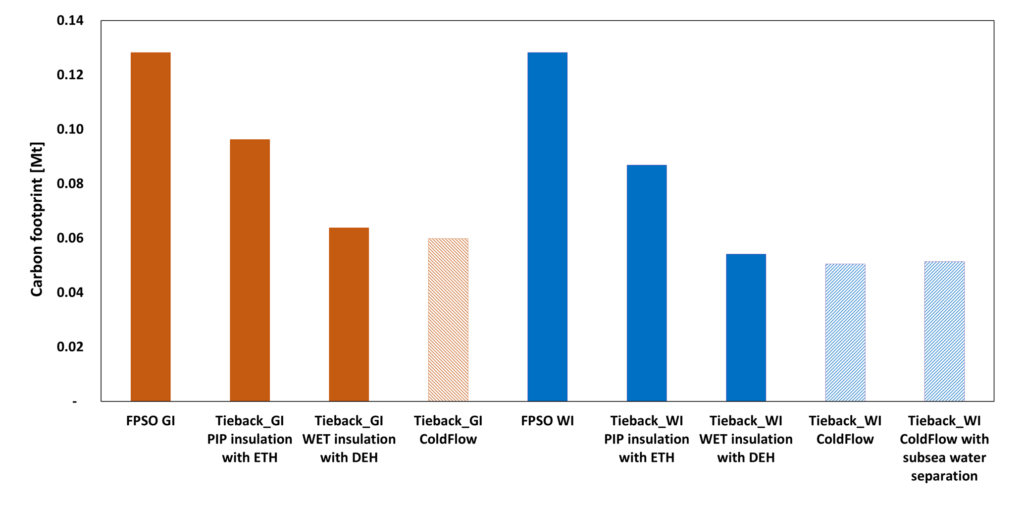

Results show that in comparison with traditional alternatives, this technology could reduce energy demand by about 385,500 MWh and 370,600 MWh for gas and water injection, respectively. This corresponds to reduced lifetime CO2 emissions of 22% and 30% for the gas and water injection scenarios when compared against a standalone FPSO development. These reductions are equivalent to around 0.3 MtCO2 for both scenarios, which is a great achievement. Please see Figure 1 and Figure 2 .

This technology offers many other advantages. Cold Flow can be more cost-effective and simpler to maintain and implement in comparison with traditional approaches. All large and costly subsea power consumers along the flowline (for heating and boosting, for example) may be removed depending on the scenario. In addition, results

indicate that the technology is not only relevant for liquid-dominated production (here water

injection, which was the initial design case) but also for production with higher gas rates. This

will extend the possible application area of the technology.

In summary, we can expect the Cold Flow technology to be an important option for many future field developments standing for a considerable part of the required emission reduction. In combination with a cost advantage, this will enable field developments that otherwise would have been discarded. For more details, we refer to our publications at OMAE 2022.

References

- OG21 – Norway’s oil and gas technology strategy for the 21st century, https://www.og21.no/

contentassets/1ba9f0520c0e449b89a429c8960b88d2/og21_rapport_innside_enkelt.pdf - Eyni, L., Stanko, M., Schümann, H., 2021, Methods for Early-Phase Planning of Offshore Fields

Considering Environmental Performance, http://dx.doi.org/10.2139/ssrn.3935491 - Schümann, H., Eyni, L., Fattahi, M., 2021, DSP8_2021_3 Feasibility and environmental analysis for

a 100 km tie-back solution with cold-flow, Project memo, LowEmission center, SINTEF - “Technical and environmental evaluation of a hydrate cold flow technique to produce an oil

reservoir using a ling tie-back and comparison against traditional development concepts” as part

of the 41st International Conference on Ocean, Offshore and Arctic Engineering (OMAE 2022) in

Hamburg, Germany in June 2022.

0 comments on “Environmental Assessment of the Cold Flow Technology”