In order to mitigate global warming we need to limit man-made CO2 emissions. One way of reducing emissions from fossil sources is to implement CO2 capture and storage (CCS) in industry. However, if we capture and permanently store CO2 from flue gases produced by burning partially or fully biomass fuels, we can go a step further and actually remove CO2 from the atmosphere. This is what the ACCSESS project will investigate, keeping in mind the importance of the sustainability of the biomass used for this purpose.

Textbook knowledge?

Many people today are aware, or have at least heard, that we are living in an ongoing climate crisis – but do we really understanding what is happening?

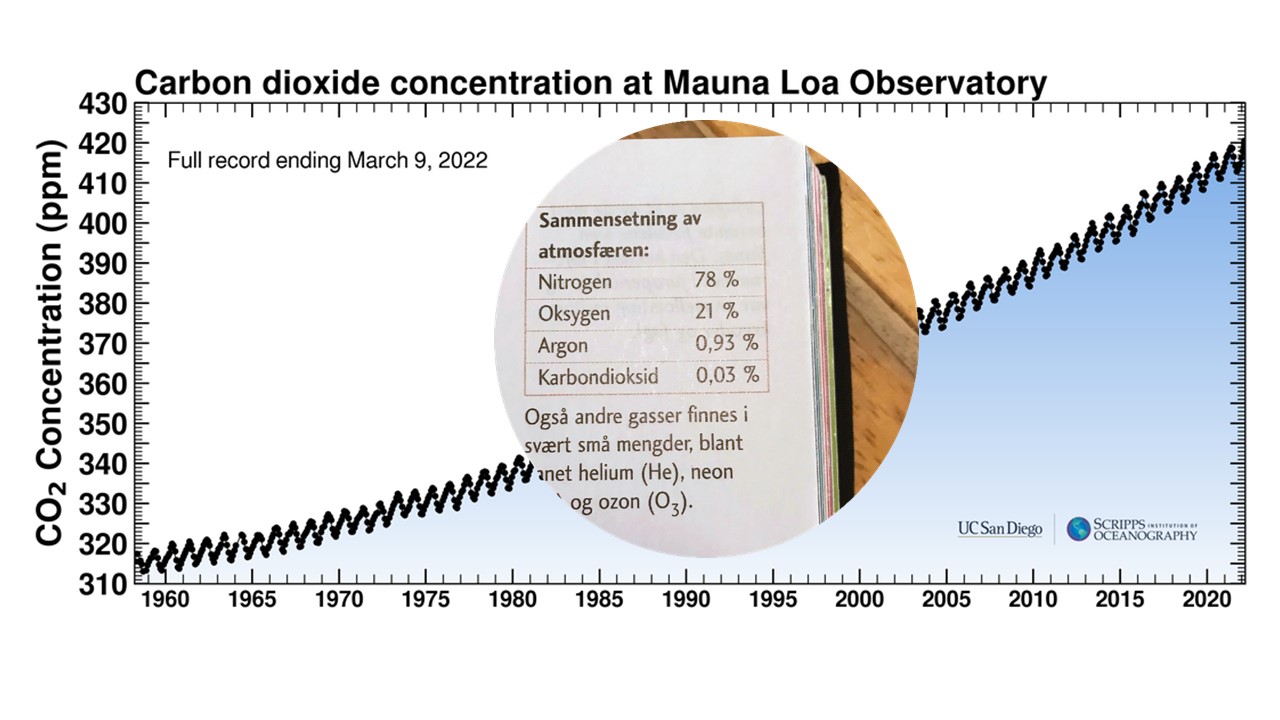

The key driver of climate change is the increasing amount of man-made carbon dioxide (CO2) emissions being released into the atmosphere, due to our increasing use of fossil fuels. According to the Keeling Curve, CO2 concentration in the atmosphere is well above 400 ppm (0.04%). This may seem like a small difference compared to the pre-industrial levels of 0.03%, but the relative difference is significant. As more CO2 is released into the atmosphere, more heat radiation from the Earth is trapped, which heats up the planet and causes climate change. According to the Intergovernmental Panel on Climate Change (IPCC), climate change is a threat to human well-being and the health of the planet.

Despite all the talk about climate change, and the fact that the Keeling curve has continuous records since 1958 that are publicly available, the ongoing increase in atmospheric CO2 concentration is not necessarily textbook knowledge. For example, according to my 14-year-old daughter’s science textbook, the CO2 atmospheric concentration is still at 0.03% – which it has not been since long before she was born. So, to repeat the initial question, do we really understand what is happening when fundamental scientific knowledge is not included in a basic textbook?

If we are to mitigate global warming, and limit the increase in global average temperature to under 1.5˚C, the IPCC points out that the time for action is now, and that we can halve emissions by 2030. The challenge may seem immense for some and very abstract for others. If the CO2 concentration has increased so much from pre-industrial levels, how can we possibly do something about it and still maintain the operation of industries that provide the jobs, goods and services that are part of our present way of life?

To make one of the possible solutions more concrete, I would like to tell you about what is happening in the EU-funded ACCSESS project. This project is not a silver bullet, but a small piece of the ongoing research and innovations needed for a more sustainable future with significantly reduced CO2 emissions.

How can we remove CO2 from the atmosphere?

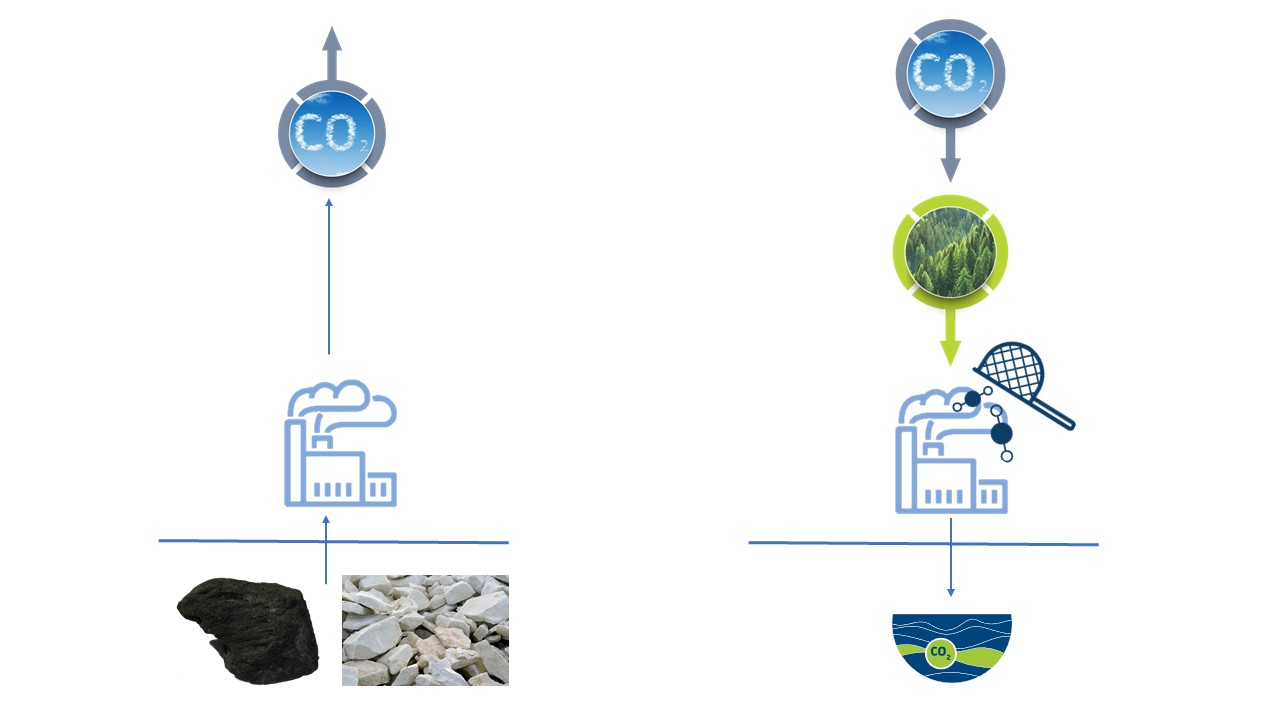

Carbon capture and storage (CCS) technologies enable us to capture the CO2 emissions from industries before they escape into the atmosphere, and store them safely underground. If we capture CO2 from industries that burn plant-based material, also known as biomass, we can actually remove CO2 from the atmosphere. This is becoming more and more known as one of the possibilities for achieving net carbon dioxide removal (CDR) from the atmosphere.

The reason for this is of course photosynthesis, where plants, with the help from sunlight, transform CO2 and water into energy-containing hydrocarbons (biomass). When the biomass is burnt, the CO2, water and energy is released again.

A European journey to demonstrate carbon dioxide removal

Testing an environmental-friendly enzymatic solvent

A main activity in the ACCSESS project is pilot-scale demonstration of CO2 capture technology at three industrial sites in three different countries, all with a flue gas that partly or fully comes from burning biomass.

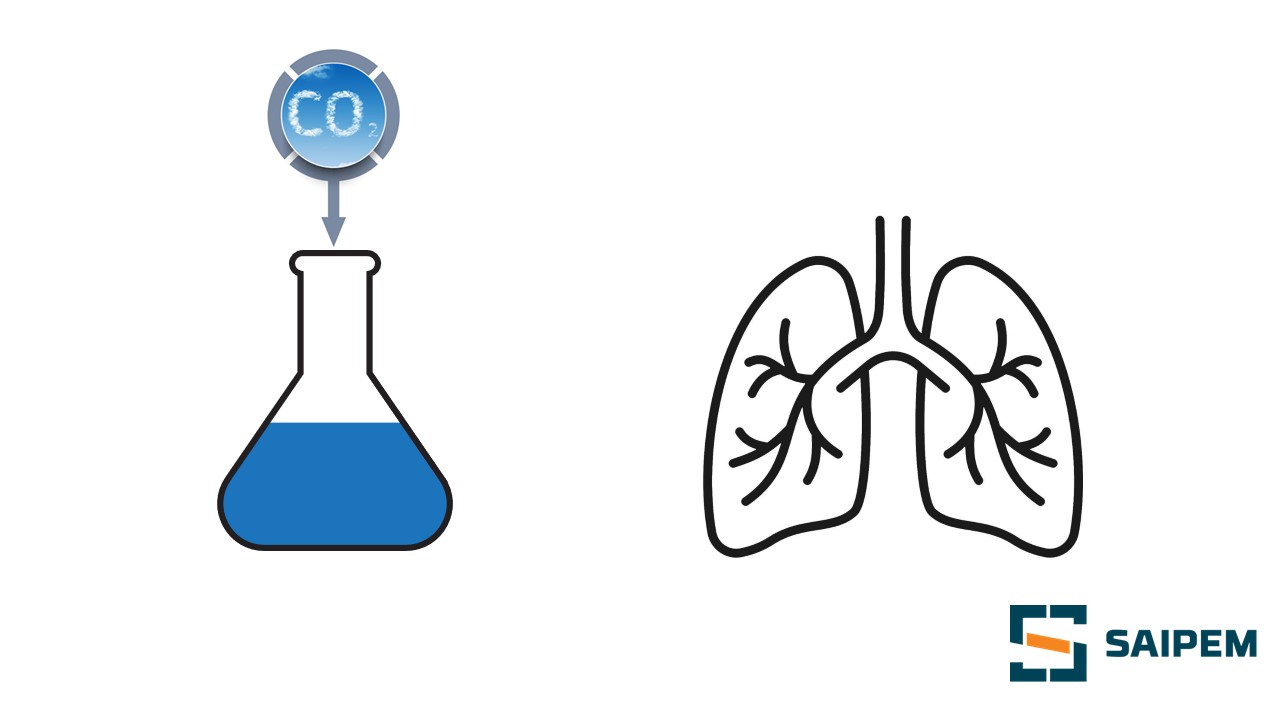

The capture technology to be demonstrated is a solvent consisting of potassium carbonate dissolved in water. Carbonic anhydrase will be added to act as catalyst for a quicker CO2 uptake and release. This technology comes from CO2 solutions by Saipem.

The first test campaign: Klemetsrud, Norway (Fortum Oslo Varme)

This enzymatic technology will be tested for the first time in Europe at Fortum Oslo Varme (future Hafslund Eco) in Norway, at the Klemetsrud waste-to-energy plant. A full-scale CO2 capture project using another technology has already been developed for the Klemetsrud plant, but its owners continue to support the realisation of CCS. This includes allowing their mobile CO2 capture test rig to be used in the ACCSESS project. As I’m writing this, this test rig is being adapted for operation with the CO2 solutions by Saipem solvent, and a test campaign is scheduled for summer 2022.

The Klemetsrud CO2 capture test rig is built in containers and therefore mobile. It hasn’t moved much so far, but this will change during ACCSESS. Let me take you on the journey…

The second test campaign: Mongstad, Norway (Technology Centre Mongstad) – adding a Rotary Packed Bed absorber

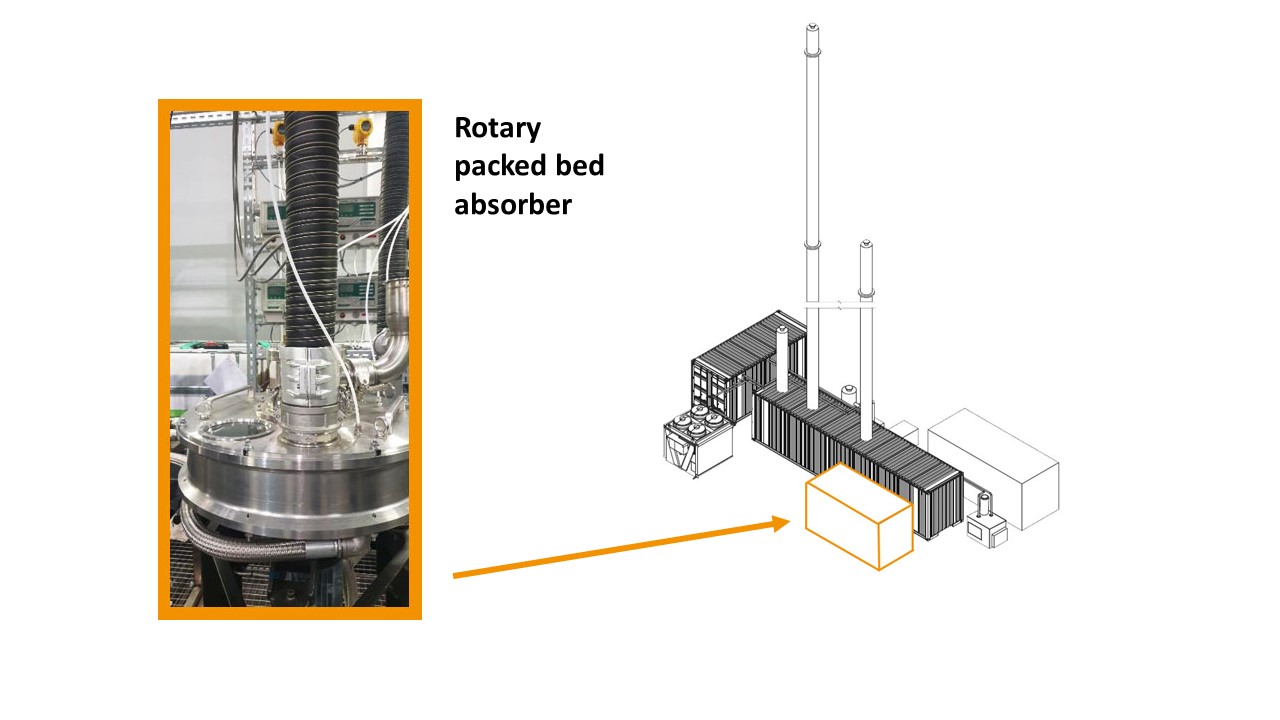

Following the Klemetsrud test campaign, the mobile test rig will be transported to Technology Centre Mongstad (TCM), where a novel piece of equipment will be added in its own separate container: a rotary packed bed (RPB) absorber.

The RPB absorber is currently being constructed by our Polish partner Prospin and its associated third party Proceler. The RPB absorber has the potential to further improve CO2 capture by generating centrifugal forces that will enable the enzymatic solvent to absorb CO2 even more quickly. The RPB absorber will be transported to TCM this autumn from Łódź in Poland. At TCM, we will run tests with both the conventional absorber and the RPB absorber in order to achieve the best possible comparison between these two types of technology.

The first 6-month test campaign: Skutskär, Sweden (Stora Enso)

After a few months at TCM, the mobile test rig and RPB will be transported to the Stora Enso kraft pulp mill in Skutskär, Sweden, for a six-month test campaign. The mill produces fluff, for e.g. diapers, from forest residuals such as treetops and branches. The biomass waste from the fluff production is burned as an integrated part of the production process, resulting in 1.2 Mtonnes of CO2 emission per year that are 100% from biomass, meaning that there is a very interesting potential for CDR here. A test run of around 6 months will provide valuable insights into how Saipem’s solvent combined with the Prospin/Proceler RPB absorber performs on this type of flue gas.

The second 6-month test campaign: Górażdże, Poland (HeidelbergCement)

Finally, from Skutskär, we will transport the technology to its final ACCSESS stop: the HeidelbergCement’s cement kiln in Górażdże, Poland – not very far from where the RPB absorber is developed and produced – where a second 6-month test campaign will be conducted. This is one of Europe’s largest cement kilns, with CO2 emissions of 2.5 Mtonne/year. In a cement kiln, roughly 2/3 of CO2 emissions are process inherent and come from the calcination of limestone, while the remaining 1/3 are from fuel combustion. When burning solid residual fuels (SRF), there will typically be a share of biogenic CO2 in the exhaust, but how much will depend on the fuel. So there is a potential for CDR from cement kilns, like the one in Górażdże.

A giant leap for industrial CDR; one of the many necessary small steps for saving the climate

Once this CO2 capture pilot testing journey is over in ACCSESS, knowledge will have been gathered across multiple levels: CO2 capture from three types of industrial exhaust gases with varying shares of biogenic CO2, as well as at TCM, using the CO2 solutions by Saipem technology. For all test campaigns, apart from the one at Fortum, we will also gain experience and insights from operating the RPB absorber.

This is a big, collaborative, European effort. But at the same time, it is only a small part of the huge efforts needed for CCS to actually be deployed at scale in industries and contribute to significantly reducing CO2 emissions.

Even if we succeed with scaling up CCS in the coming years, I don’t think my daughter will ever experience CO2 levels below 400 ppm, no matter what her textbook says. Regardless, we owe it to her and all other young people in Europe and the rest of the world, to do what we can to reduce CO2 emissions as much as possible, and even achieve a net removal of CO2 from the atmosphere. I hope that ACCSESS can serve as inspiration for more creative and collaborative CCS partnerships that can contribute to realising the necessary drastic reductions in CO2 emissions.

This blog post is based on a presentation given by the author at Trondheim Tech Port on 28 March 2022, but was not finalised until after the release of the third part of the Sixth Assessment Report, Climate Change 2022 by the IPCC.

The ACCSESS project spans over CO2 capture and use in industry, CCS chains and CCS in a societal perspective. The focus in this blog is on the demonstration of CO2 capture at pilot scale. You can discover more about the project on our website: projectaccsess.eu.

Want to hear more from the ACCSESS project? Subscribe to our newsletter on our website and follow us on LinkedIn to stay up to date on the latest news and developments.

0 comments on “ACCSESS: A Technology Collaboration for Carbon Dioxide Removal”