Most people can relate to wood stoves and wood-burning, and many enjoy lighting their stoves or warming themselves by the fireplace after a skiing trip. Wood-burning is all about the “hygge” factor and effective heating, whether in your living room, home or holiday cabin.

Many people think they know exactly how to light their stove or wood fire. But how should we burn the wood to ensure that we get the most heat out of it in an environmentally and climate-friendly way? And how environmentally and climate-friendly are wood stoves anyway? Well, it’s all down to you and the type of stove you have.

Lighting from above gives most benefits

Work by SINTEF Energy Research and other research communities has shown that if you light the wood in your stove from above, using logs at the base and kindling/chips at the top, you will reduce particle emissions by between 50 and 80 per cent and achieve a more even combustion process. This video shows how easy it really is:

I recommend that you take a look at the user manual that came with your wood stove. The manual will give you tips about the best way to light your stove. If you want to find out more about lighting your stove, I recommend that you read Vedfyringens ABC (The ABC of Wood Stoves, in Norwegian).

Lower emissions limits for wood stoves are being introduced

There is a close link between wood-burning and the “hygge” factor. No other combustion technology can provide the “hygge” experience while at the same time acting as the main source of heating in our homes and cabins. At a time when emissions have to be cut on all fronts – both polluting emissions and greenhouse gases – can we continue to cosy up in front of our wood stoves with a clear conscience? New legal requirements are constantly being introduced to regulate this traditional means of heating – in response both to pressures to reduce emissions, and to changes in the regulations governing energy efficiency in new-build homes. Of course, such requirements are very sensible, but they also mean that wood stove manufacturers have to think innovatively in order to keep both consumers and the public authorities happy.

Consumers need less heat to warm up their modern homes, and this puts demands on the heat output specifications for new wood stoves. You can still open a window if it gets too hot, but this is hardly the smartest thing to do if your new home is designed with a balanced ventilation system. This can make the economics of using your stove much less attractive.

Is wood-burning environmental and climate-friendly? The answer is yes – provided we do it right.

The public authorities want lower levels of polluting emissions and a reduction in greenhouse gas emissions. Since biomass is by definition CO2 neutral as far as the CO2 emissions are concerned, greenhouse gas emissions from wood burning stoves are comprised primarily of methane (CH4). New limits for polluting emissions are on the way in. The old and relatively high limits, which have remained unchanged for too long considering the technological advances, will soon be a thing of the past. This will also contribute to a reduction in greenhouse gas emissions.

Wood stove manufacturers are well aware of this situation and are battling for their existence in a world where alternative heating technologies are taking their share of the market (Link: blog in Norwegian). In the first instance, these alternative technologies have a major advantage – either because they are run on electricity or are electrically regulated.

Wood stoves, which involve a single batch of logs lit manually one at a time, are thus at an immediate disadvantage compared with these alternative heating technologies. This is because burning logs in a wood stove involves a so-called transient combustion process, in which the material being burned is constantly changing its nature throughout its combustion. This means that heat generation is also continuously changing, which in turn also means that the heat component conducted through the stove wall and finally transferred out into the room is also constantly changing. So, is wood-burning eco-friendly? This is a legitimate question and the answer is – yes, provided we do it right.

What will future wood stoves look like?

Thus the potential to balance the release of heat into a room, as well as the opportunity to extend the combustion cycle or increase the heat storage capacity of stoves are very interesting topics for research. Possibilities include the use of heat-storing materials such as soapstone, phase change materials (find out more about these in this blog) and, in some cases, water as a storage medium (water jacket – in Norwegian). Of course, stoves can be made smaller, but this places limits on their practicality, aesthetics and the “hygge” factor. Whatever you do, emissions must not increase. Ideally, they should be reduced.

Automatic control of the combustion process, which regulates the air supply to the stove’s various air inlets during the combustion cycle, provides greater opportunities for flexibility and reduces dependency on the person (operator) lighting the stove. In this way you kill two birds with one stone in that you achieve better combustion conditions while at the same time reducing the need for the operator to adjust the air damper.

Stove development Option 1 is to run to the labs operated by wood stove manufacturers or research institutes, and base the work entirely on experiments and empirical data. This is the traditional and by far the most popular method, carried out with little or no support from data-based computational tools, and without any consideration of automatic control. Such an approach can quickly become very demanding in terms of time and costs, and the result may be far from optimal.

Option 2 involves combining the experiments and empirical data applied in option 1 with automatic control of the combustion process. By regulating the air supply to the air inlets during the combustion cycle in response to flue gas temperatures and oxygen concentrations in the flue pipe, we create an opportunity to reduce the emissions of non-combusted components, both particles and gases, including the greenhouse gas methane (CH4).

The challenge linked to this option is to create a control algorithm, based on a so-called Proportional Integral Derivation (PID) controller that is flexible and capable of adapting to a wide range of stove designs, operating conditions, fuels and operators. A little electricity will also be needed, but systems are being developed that do not require access to mains electricity.

For two years, SINTEF, together with several wood stove manufacturers, researched into this option as part of the innovation project called AEOLUS, and developed a working concept. This concept is now being further advanced and generalised as part of a new project called AEOLUS+, with funding from the Research Council of Norway.

I can say with my hand on my heart that log combustion in a wood stove can be regarded as the most complex combustion process found in nature.

Option 3, which is no longer the stuff of science fiction, involves the use of simulation tools based on physical models that describe in detail what happens during the combustion process. Such tools offer us previously undreamt-of opportunities to study the influence of the fuel, stove design and operation on the combustion process, and thus also the emissions and heat output generated during the process. Theoretically, wood stove performance can be optimised simply by adjusting the key combustion parameters.

By combining Option 3 with Options 1 and 2, we will be able to produce the ultimate wood stove – based on a detailed understanding of the combustion process, which is controlled automatically by automated regulation of the air supply and the stipulation or validation of key control parameters, all based on a few experiments.

Unfortunately, there is probably still a touch of science fiction linked to Option 3 because I can say with my hand on my heart that log combustion in a wood stove can be regarded as the most complex combustion process found in nature. It requires a detailed understanding of what is happening during the combustion process, and an ability to construct models that describe the process in sufficient detail. Sufficient is the key word here, because when simulations become too complex, computing power places constraints on the level of detail we can achieve.

Clean-burning and efficient wood stoves – we’ve come a long way

The project WoodCFD was a skills development project funded by the Research Council of Norway and four wood stove manufacturers with the long title “Clean and efficient wood stoves through improved batch combustion models and CFD modelling approaches”. CFD stands for Computational Fluid Dynamics.

- If you want to find out more about WoodCFD, you can read the handbook issued by the project.

This probably sounds a little, or perhaps very, dull and tedious to many people. But it was in fact a very exciting 4-year project in which SINTEF Energy Research, together with NTNU, studied very closely the different factors that influence combustion in, and heat output from, wood stoves, as well as the impact of heat output on the levels of heat comfort experienced in different types of buildings and in a variety of climates.

Our work resulted in models and modelling approaches that have come a long way in making it possible to base future wood stove technology development on Option 3 simulations, and achieving optimal control of the combustion process by the introduction of automatic control devices.

We have created simulation tools for wood log combustion

Specifically, the WoodCFD project addressed both the development of a detailed wood log combustion model and the correct selection and use of a series of other models used to encompass all the component models that have to be included in the simulation toolbox.

Testing of the simulation tool involved simulations of the entire combustion process taking place in a real wood stove, including all essential design details such as the heat storage properties of the materials making up the stove. The effects of the resulting heat output profiles on levels of heating comfort in rooms and buildings were studied in detail.

In order to perform adequately detailed simulations throughout an entire season of stove use, models were developed for inclusion in building simulation tools, which also take sufficient account of heat circulation in individual rooms. A Ph.D. student, a post doctorate and a number of other students contributed to the project, together with their tutors and research scientists at NTNU and SINTEF.

Future research challenges

The most important thing we lack now in our attempt to obtain a detailed and comprehensive wood stove simulation tool is a fully integrated tool in which input is represented by start values only and all other values are computed during the course of the combustion process. This requires direct coupling between the decomposition of a wood log and its surroundings. There is also a need to optimise the simulation tool in order to make it as efficient as possible. This is demanding work and fully justifies a new research project, that will provide a comprehensive wood stove simulation tool that can make an effective contribution to the development of future wood stoves. This can be supplemented with precisely selected laboratory experiments and guidelines based on building integration simulations and input from consumer surveys in order to ensure the optimal integration of wood stoves in tomorrow’s energy efficient homes. Optimal control of the combustion process can be achieved by introducing automatic control devices. In this way, wood stoves will be able to compete with pellet stoves when it comes to emissions and heating comfort without any reduction in the “hygge” experience – which only wood-burning stoves can provide. The ultimate goal is the development of the sustainable wood stoves of the future through optimisation of the stove and its entire value chain, including its building integration.

What about your old wood stove? It may be releasing high levels of emissions.

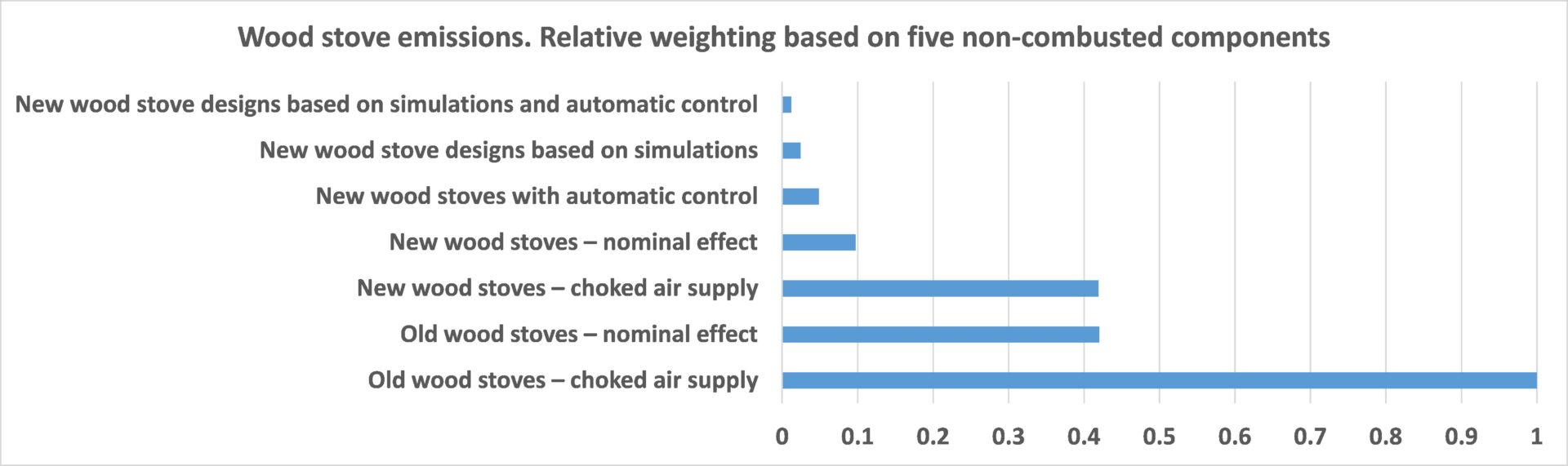

If you have a wood stove that was made before 1998, you stand to gain a great deal, both in terms of emissions and energy efficiency, if you replace it (Link: in Norwegian). It should be said that some antique and other old stoves can function relatively well under optimal combustion conditions, although far from as well as new stoves. This is because new stoves work according to a more advanced combustion principle based on staged air combustion. They are also designed to work significantly better than old stoves when you produce low levels of heat (choke the air supply). The diagram below is a simple but realistic illustration of emissions levels from old and new wood stoves, compared with anticipated emissions from the wood stoves of the future.

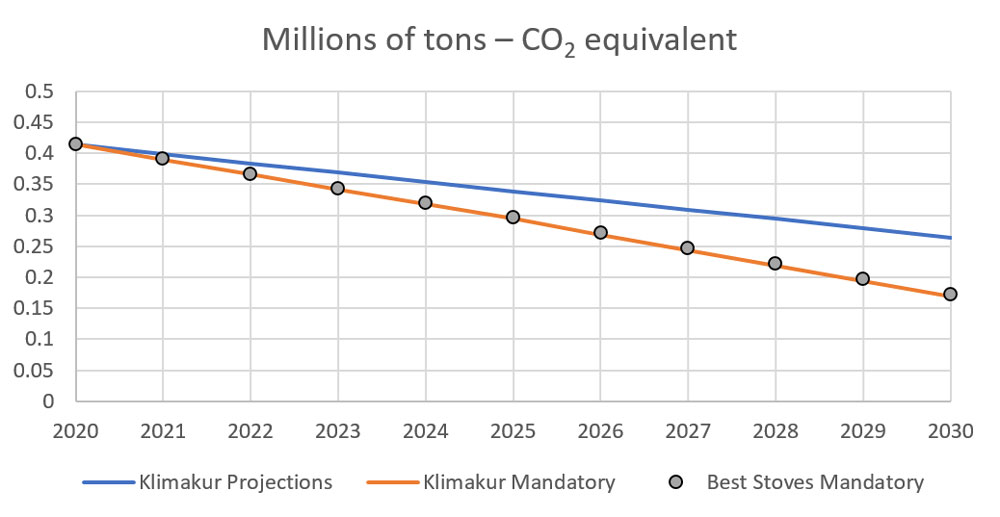

Greenhouse gas emissions from wood burning stoves, primarily methane, and the potential effect of mitigating measures have been thoroughly analysed by Klimakur 2030 (link in Norwegian). Old wood burning stoves are steadily being replaced by modern ones, which will over time contribute to a reduction in methane emissions. But there’s a wide difference between the average new stove and the absolute best one. Klimakur 2030 focused on two measures to further reduce greenhouse gas emissions from wood burning: 1- Upgrading old wood stoves to the best available ones (instead of a new but average one); 2- The mandatory replacement of old stoves (starting in 2021) and of more recent, average stoves (starting in 2026) by electric heating. However, since the best wood burning stoves now have very low methane emissions, a mandatory replacement of old and average stoves to the best ones will result in almost the same greenhouse gas cut as the proposed transition to electric heating.

Since Norway imports non-renewable (fossil-based) electricity – primarily during the wood burning season – a transition to electric heating will not necessarily result in a net reduction of greenhouse gas emissions compared to a transition to efficient wood burning stoves (especially when the electric heating is done with less than optimal electric radiators). The figure below shows the Klimakur 2030 projections, together with a curve showing the anticipated results of a transition to the best wood burning stoves instead of heating with electricity presumed to be renewable.

Wood burning requires no upgrades to the power network and contributes to energy security – while creating “hygge”. These factors speak in favour of the continued use of wood burning stoves in the future.

So, it is clear that you can do a lot yourself, both for the environment and the climate, by simply replacing your old wood stove (preferably with one of the best ones on the market) and avoiding reduced levels of heat production through choking the air supply. After that, it’s all about embracing our future opportunities – the introduction of automation and new stove designs based on a detailed understanding and simulation of the combustion process. However, this requires research – and development.

The ultimate goal is the development of the sustainable wood stoves of the future through optimisation of the stove and its entire value chain, including its building integration.

So, enjoy the wood stove season, but remember – don’t burn your Christmas tree in the wood stove when Christmas is over!

This article was originally published on December 20th, 2019 and updated on November 28th 2021.

Pingback: Don’t burn your Christmas tree in your wood-burning stove!

Great article Øyvind! Indoor pollution from stoves is responsible for deaths of thousands of people each year. Thankfully, those numbers are reducing, and are already quite low in Western world. Still, inefficient burning of wood releases toxic gases such as nitrogen dioxide, and carbon monoxide. These can be really harmful.

Get at better Chimney – problem solved ?

Pingback: Is heating with wood eco-friendly? - #SINTEFblog

Anyone who leaves near a neighbour that has a wood burner will be able to testify that these things are horrible pollutants. Burning wood when you have gas/electric heating is selfish and giives two fingers to the environment.

Efficient, modern woodstoves have virtually no smoke coming from the chimney once they reach normal operating temperatures and conditions. The simple fact is, and one rarely mentioned, that woodburning is way more affordable than gas or electricity. Depending on whether I have wood delivered or cut it myself I can heat my home all winter for what it would cost for anywhere from a few weeks to a few months worth of propane or electricity. Heating with wood is not a matter of selfishness for many, it is a matter of survival. Without the option of wood many families would be huddled under piles of blankets several months a year.

???

I’m with you. The air here is choking from log burners. The sooner these things are banned in built up areas the better.

Anybody that has a modern wood burner stove can testify as long as you burn seasoned wood there is no smoke visible from the flue and is also CO2 neutral,burning gas that has been locked away for a milenia is increasing CO2 levels and is responsible for warming the planet on an exponential level

Gas is a non renewable energy source, and electric might be renewable or then again it might not be, depending on how the electricity is produced. Local wood on the other hand is a renewable energy source. Electricity here in Spain is a very expensive heating option, fluctuating dramatically in price depending on demand. Storm Filomena brought 70 cm of snow to the Mediterranean, Covid poverty and the price hike in electricity and gas meant people went without heating for a month. People in the countryside were almost unaffected relying on alternative and sustainable energy sources. All is not bad as far as wood burning is concerned. We also burn almond and hazelnut husks as well as olive stone in specially designed rocket stoves which only produce smoke on ignition.

I live in a area designated as a “smokeless zone”. Every winter the air my family breathes is now loaded with carcinogens…. from log burner. It is impossible to walk my dogs and avoid the stench. I come home with my clothes and hair smelling of smoke. All the houses here have clean gas central heating so the log burners have been fitted for “entertainment purposes”. I’m sure the owners of these things would have not fitted them if they knew the real facts. These things produce massive amounts of pollution even when used “properly” which most owners won’t have a clue about doing. The sellers of these products don’t tell the truth. If you want the facts see woodsmokepollution.com

I’ll do a deal with you Colin,I think owning a dog is sticking 2 fingers up to the neighborhood because where I live there are a lot of owners that let their dog out into the garden unattended that constantly bark at each other across fences,so if you get rid of your dog I’ll get rid of my stove

If I see you walking your muts (horrible Creatures, creating foul smelling waste products) I’ll close the damper to smoke out. People such as you must live a life of permanent misery, looking to stop anything that you don’t agree with. I hate dogs, they should be used for meat. Happy moaning.

Like,Colin Tinker. The village I live in has all too many wood burning stoves and in the evening when I’m walking my dog the air is foul and full of smoke,so much so I’m considering taking the dog in the car where the air is safe to breath. You can see the wet logs piled up in their back garden and with all the rain ,no way are they burning kiln dried wood.Unlike Colin I don’t live in a smokeless zone. He should contact DEFRA as I think he has a legitimate case.

As far as I can see .Operating one of these stoves properly is quite technical so no wonder there’s so much smoke getting pumped out into the air.After all you don’t expect everyone who owns a car, to know the workings of the internal combustion engine.

A summary response on the above replies:

Poor wood stoves, wrong stove operation and poor wood quality give excessive emissions, and this is amplified in areas with dense population and especially for atmospheric and topographic conditions that prevents a proper dispersion and dilution of the emissions once emitted. Much can be improved by installing good wood stoves, operating them correctly and using good quality wood. In extreme cases, and not because of the wood combustion alone, pollutants concentrations can become too high, and a number of other emission sources can also be contributing to this, e.g. cars. In such extreme cases, the local authorities should evaluate the situation and take the appropriate actions to regulate the reasons for the high emissions. To improve the situation, get your national/state or local authorities to support the replacement of poor wood stoves and promote the education of the wood stove owners, in the proper operation of the stoves – for a brighter, healthier and eco-friendly future. This needs to be coupled with increased awareness among the wood stove owners themselves and willingness to make a real effort to contribute to this improved future.

Are council’s going to make bon fire night illegal.

Pingback: These simple tips will help you reduce your wood-burning stove's environmental footprint [with video] - #SINTEFblog

About 30 years ago I remember stopping for a drink at the pub, every time my eyes watered from cigarette smoke, when I got home my clothes stank of cigarette smoke, I didn’t smoke but I had to put up with the fact people smoked in pubs. I don’t mind the wintery smell of wood smoke in our village, it doesn’t make my eyes water nor my clothes stink, but then it is a small village. In fact I quite like the winter wood smoke scents the stoves produce, reminding me of the countryside and days gone by. I suppose that it depends on type of wood, stove and rate of burn among other things but I find diesel much more offensive.

Pingback: New project: Sustainable wood stoves through stove, building integration and value chain optimisation - #SINTEFblog

Just read this article and I can say these are awesome great tips on how to take care of your Wood Stoves in Claremore, OK. I will be using this tips for my own clients so that there Wood Stoves in Claremore, OK go smoothly!