Previous solutions are based on injection of chemicals, typically MEG. SINTEF Energy has developed Direct Electrical Heating (DEH); a cost effective (OPEX) and eco-friendly alternative.

The DEH concept is to apply an electrical current through the steel pipe itself, heating the pipe content above critical temperatures for hydrate/wax formation.

- Find out more about SINTEF’s expertise on Direct Electrical Heating (DEH).

Direct Electrical Heating is developed and qualified in close cooperation with Norwegian oil companies, cable manufacturers and installation companies. Since 2000, the method is field proven at more than 40 installations with very good performance and under various operating conditions (keep warm during shutdown, reheat from cold and continuous heating).

SINTEF Energy has participated in all previous DEH development projects. Our contribution typically includes:

- rating of the electrical system (DEH cables and topside power supply),

- anode design for the current transfer zones

- and interference analysis with regards ac corrosion risk.

Direct electrical heating – how it works

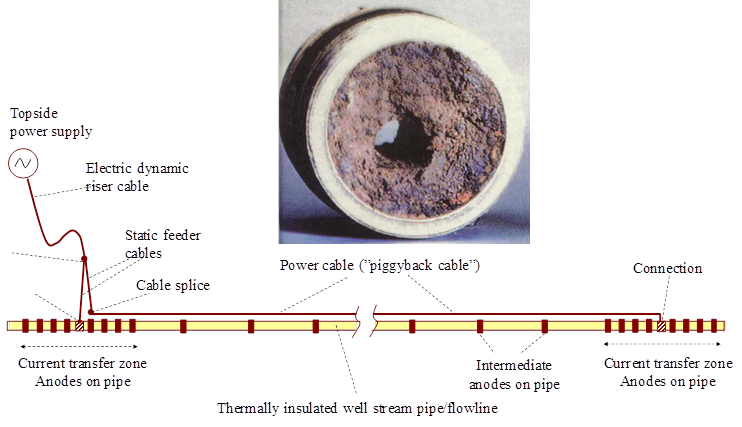

The DEH working principle is that the heated flowline is part of an electrical circuit, heating the pipe content above a critical temperature limits for hydrate/wax formation. The DEH system includes a riser cable down to the sea floor, a feeder cable towards the flowline and a DEH cable piggybacked to the flowline all the way along the heated section. At the far end, the piggyback cable is connected (grounded) to the pipe steel. Analogous, a return cable is connected to the steel pipe in the near end. Thus, the return current is divided between the steel pipe and seawater. The heat development (W/m) is caused by power losses in the steel pipe and piggyback cable, including the electromagnetic coupling between the cable and the steel pipe.

Read more on the DEH fact-sheet. Heating of pipelines (DEH)_small

Originally written by Harald Kulbotten/new version 15. June 2018.

Comments

I am working on a Project that plans to use permanent DEH for a 1000 metre deep 18″ Gas Production Flowline.

One of the main topics of discussion is the set up and Commissioning Phase and the requirements for Water to be in the Flowline when Load Testing and setting up the DEH Power Systems before Hydrocarbons are introduced.

Wartsila provided documentation to state that their system needed Water in the Flowline for initial Power Up, Capacitance testing and Full Load Testing, is this the case for all Topsides DEH Systems IE ABB, Siemens etc,

My experience with BP on SD2 was that Water was required to be in the Line for testing.

I am being told that that new Technology exists that may not require Water in the Line for Commissioning / First Test Run / Load Testing / Calibration

Could you possible provide any feedback on this

Hi Azam,

DEH is also used for continuous operation. The required heat input to the flowline is in this case lower, typically about 50% of the keep warm/reheat cases. Electrothermal analysis must be performed with information of flow conditions entering the DEH section (inlet temperature, flow mix, flow rate, thermal coefficient etc). The challenge is not to overheat the DEH cables and in the same time achieve sufficient heating to meet required target temperature of outlet flow. The analysis are based on predictions of future flow situation

Best Regards

Are Bruaset

Hello.. Based on the articles that I’ve read, DEH is typically utilized during the shutdown or intermittent condition. Is there any DEH technical limitation that I need to manage if I want to use it for a continuous operation? Appreciate your advise. Thanks.

Thanks, for sharing the information, it’s very informative post!

The longest DEH system installed and in service is 43 km. This system (single phase) is operated at approx

27 kV (terminal voltage). The primary limitation factor regarding length is the insulation level for the cables and accessories, but also the variation of the generated power in the pipeline the length should be limited to approximately 50 km. Heating of longer pipelines can be achieved by modifying the system, which can be done in different ways:

– By using a midpoint connection pipeline interface, such that the total heated length can be increased to

2×50 km.

– By using a three phase supply system, i.e. a common three core power cable feeding three sections. Thus the pipeline will be heated in sections, and separate transformers are required in order to split each section galvanically. A “subsea design” with a transformer and reactive compensation located subsea will reduce the size of the power supply cable considerably. A three phase DEH system with midpoint connection is possible for pipeline lengths up to 300 km. However, the required power for maintaining the target temperature in the pipeline will determine the maximum possible heated length.

I am looking at a 24in crude pipeline that needs to be heated and kept above 40Deg C and includes a 230km section subsea. What is the present technology limit on length of DEH subsea pipeline.

Hello Ennio, Sorry for the late reply. The answer to you question is below. Best regards!

Though the heat generation is determined by the resistive losses in the pipe steel, the efficiency depends on on the proximity effect related to the gap between the cable and the pipeline. Thus the magnetic permeability of the pipe steel is one of many parameters affecting the system impedance.

“supply cable laid as close as possible to the pipeline to achieve a maximum heating efficiency.”

I have experienced a common misconception in the industry, in that this technology exploits the process of induction heating. I don’t understand the point above. If the heat is generated by the AC current passing through the steel wall of the pipe, how is the efficiency of the system affected by the proximity of the supply cable to the carrier pipe?

This is a good company. If they have an article, I want to read it so I can have a knowledge about electrical.

Nhorman,

my apologies for late reply to your comment!

At an IEEE conference in 2005 we published a paper describing the method and requirements for designing the system.