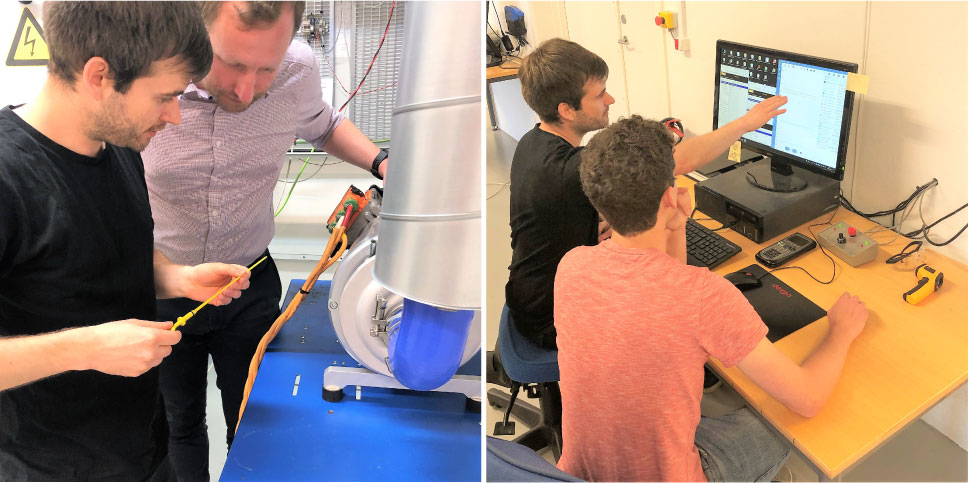

SINTEF employees joined the Factory Acceptance Tests at ROTREX A/S headquarter in Copenhagen, Denmark to inspect the improved turbo compressors for an open loop heat pump system.

The main component in an open loop heat pump system is the compression device

As part of the EU-project DryFiciency, SINTEF is developing and testing a novel compressor type together with ROTREX: a so-called turbo compressor. The challenge was to design a gearbox which results in a rotational speed of up to 80.000 rpm for an impeller size of 15 cm and at the same time seal the compressor room from the drive unit. This week the factory assembly tests were finalized successfully and the design is approved for a heat pump application and other steam compression processes.

This is an important step forward in achieving the main goals of the project: Improve process energy efficiency by up to 80%, reduce production cost by up to 20%/kg and reduce CO₂ emissions up to 75%.

The compressor will be used to recover the drying energy of steam drier and upgrade it into usable process heat. In steam drying processes, products are dried in a steam atmosphere. Today, steam is circulated and reheated by a natural gas burner, emitting the greenhouse gas CO2. The water removed from the product is present in the form of excess steam.

Usually, the energy in the excess steam cannot recovered, because there is no heat demand at this low temperature, and it is therefore wasted. Open loop heat pump systems, also known as Mechanical Vapour Recompression (MVR) systems, allow the reuse of the excess steam to heat the process. Compressors increase the pressure level of the excess steam to condense it at higher temperatures.

The consortium are developing MVR system

The MVR system developed by the DryFiciency consortium uses advanced, low-cost, turbo compressor technology originating from the automotive sector. Due to further development it is possible to achieve condensation temperatures of up to 160°C at a combined pressure ratio of 6.4, when steam is compressed over two stages. For comparison: with standard technology it is only possible to achieve a pressure ratio of 2 in a two-stage system. Thus, the new prototypes are pushing the limit significantly and enable completely new applications.

What’s next?

The upcoming assembly of the advanced turbo compressors will be followed by tests on the entire heat pump facility at SINTEF Energy Lab at Blaklia in Trondheim. Due to the successful compressor tests, the intended pressure ratio will be demonstrated. Site acceptance tests at Blaklia are planned for June 2019.

Pingback: Successful Factory Assembly Tests for novel Steam Turbo Compressors – Dry-F