SINTEF and the NGI have begun work on a CLIMIT Researcher project with the title: “SPHINCSS-Stress Path and Hysteresis effects on Integrity of CO2 Storage Sites”, where we will examine potential mechanisms that lead to increased stresses in and around the storage reservoir.

Laboratory testing and numerical modeling

As the project name implies, history is also important, and one would expect different stress patterns for an oil reservoir that was depleted and filled with CO2 than for a virgin, permeable formation with the pores initially filled with brine. The project will include both laboratory testing and numerical modeling, with a post doc as main investigator, Nicolaine Agofack.

In addition to SINTEF and NGI, project partners include Ecole des Ponts in Paris, Curistec in Lyon and Lawrence Livermore National Laboratory in California. All partners are world renowned research institutions in the field of rock mechanics, rock physics and geochemistry.

Simple and ingenious

To reverse the usual operations related to oil and gas extraction seems like obvious, when it comes to storage of CO2.

The idea is both simple and ingenious: hydrocarbons have been found and recovered precisely because the geology has done its job, and assured sealing of the reserves deep in the underground through millions of years.

Therefore, we can easily reverse the process and help the climate by quickly disposing of CO2 in the atmosphere by storing the gas in the subsurface for all eternity.

And it is precisely what has been performed with great success by Statoil on the Sleipner field for more than 20 years.

So why should we still need more research on CO2 storage?

Seen from the rock mechanics perspective, there are two reasons to continue the research:

- the first is that the Sleipner and all other storage pilots around the world are small scale operations

- for us to make a difference and contribute to the Paris agreement, it would take many more and much larger storage initiatives

Development of models

In future commercial operations, one would inject from many wells in large formations and aim to maximize volumes, suggesting that it is becoming more challenging to ensure that no leaks occur.

The second reason is that not all of the pilots experienced injection as expected:

- on the Snøhvit field increasing pore pressure was observed that was not in accordance with the models and the injection had to be stopped due to a heightened fracturing risk

- on the In-Salah field in Algeria this actually happened, with measurable heave of the surface directly above the storage reservoir

- in the Decatur-pilot in Illinois large (but harmless) micro-seismic activity was registered, far in advance of the actual CO2-front, etc.

These events point to the fact that our models still do not manage to predict entirely the events occurring in underground operations.

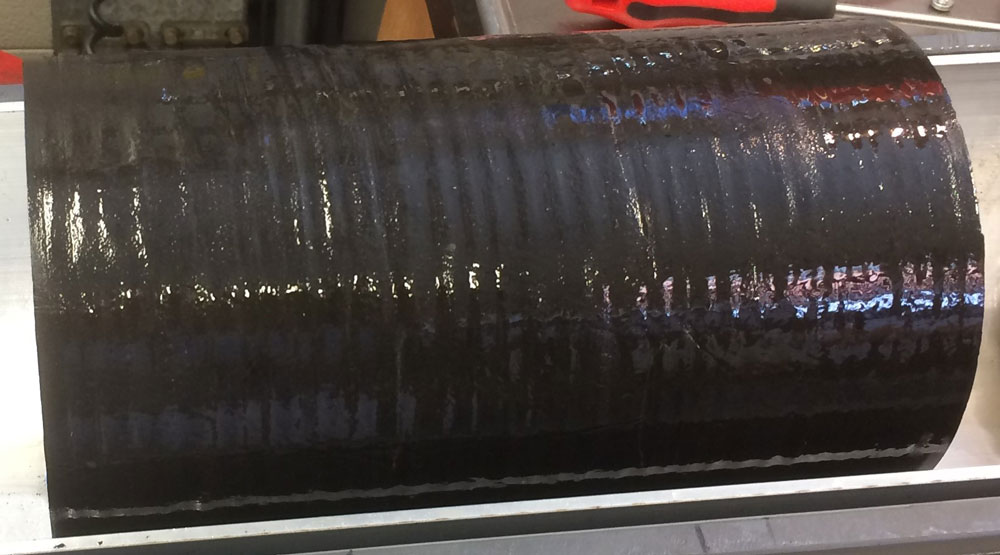

Statoil has an observer and adviser role in the project, and we have received donated shale core material being tested these days both in Oslo and Trondheim. The core is taken from the Draupne formation, which is the cap rock in the area that includes the Smeaheia field. Smeaheia is the storage location in the national pilot where the entire CO2-value chain (CCS: CO2 capture and storage) is being tested, with the capture of up to 3 industry sources, ship and pipeline transport as well as offshore storage.

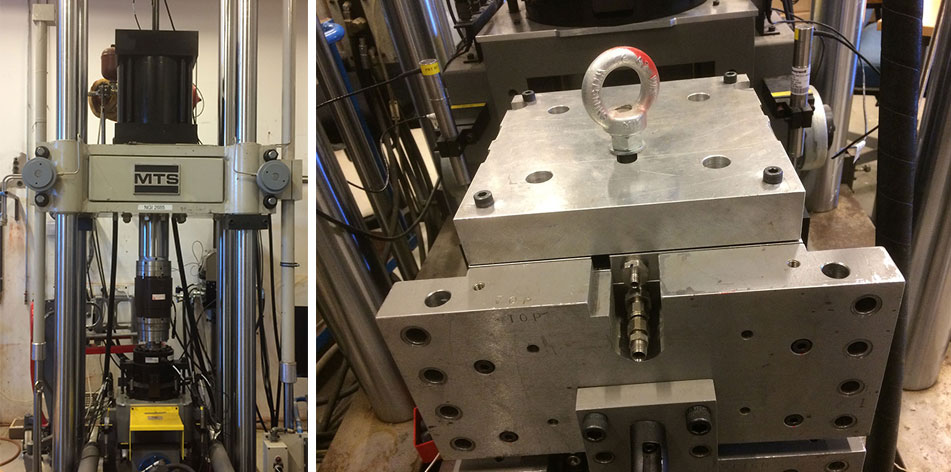

NGI uses its unique shearbox to test leakage risk as a function of stress in a natural fracture in the Draupne shale.

SINTEF is running:

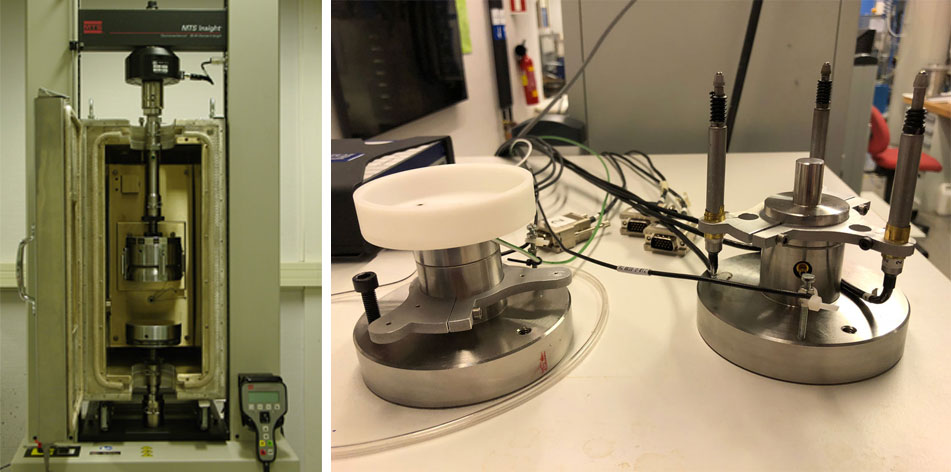

- compression tests on small specimens where we want to document potential strength and stiffness changes after exposure to CO2

- so-called creep tests, where one looks at slow deformation under constant applied stress (creep)

These tests have the ambition to test whether or not any fracture in the shale (and thus a leakage path upwards) can heal by itself with increased creep under contact with CO2.

Pingback: Geomechanics for CCS: A Positive National Collaboration - #SINTEFblog