Written by Chief Scientist Dr. Daryl Powell (SINTEF).

Eight experienced lean authors provide our views on the role of theory in lean research. We also identify several interesting avenues for future studies.

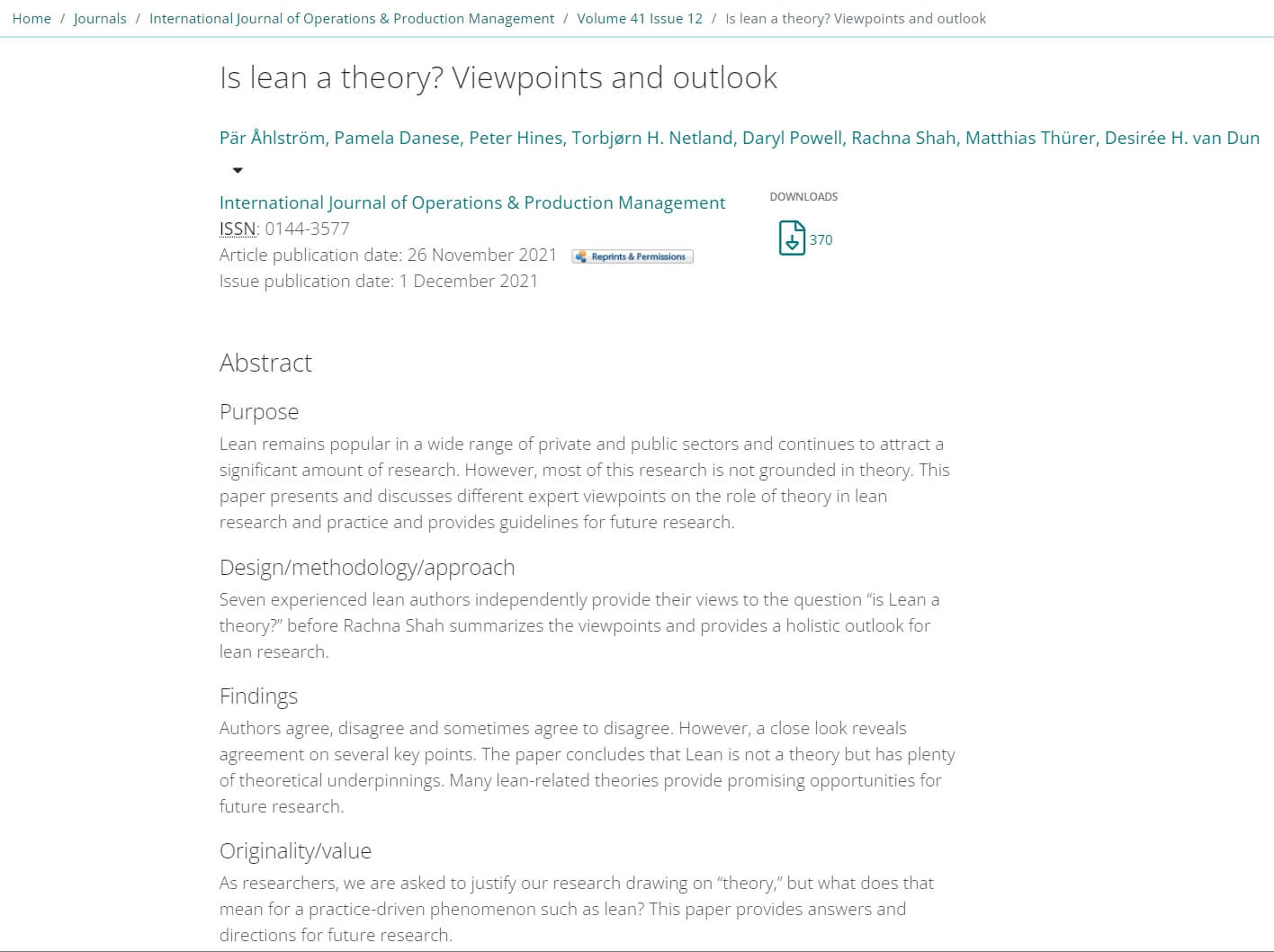

There are many views on what lean is. The article is published in the International Journal of Operations and Production Management (IJOPM).

The Midlife Crisis of Lean Research

It all started at the EurOMA 2020 Special session Lean Research: 30th Anniversary and Mid-life Crisis. During the session, a panel of five leading lean scholars engaged in deep discussion and shared insights to reflect over 30 years of lean research.

Following the conference, and being joined by an eighth lean researcher, the participants agreed to further develop the discussion – and set about writing a viewpoint article for IJOPM with the title Is lean a theory? Viewpoints and outlook. The article presents and discusses the different experts’ viewpoints on the role of theory in lean research and provides guidelines for future work.

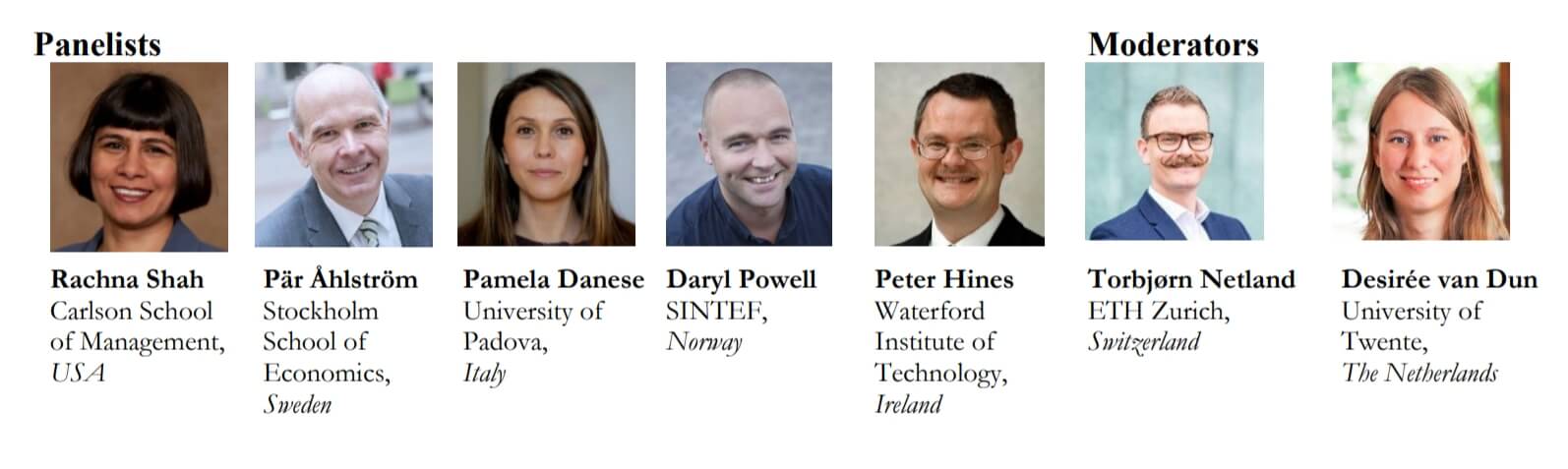

Panelists and Moderators of the EUrOMA 2020 Special Session Lean Research: 30th Anniversary and Mid-life Crisis.

Panelists and Moderators of the EUrOMA 2020 Special Session Lean Research: 30th Anniversary and Mid-life Crisis.

The Theories of Lean

Lean as an umbrella concept for business improvement (Åhlström)

In the article, Prof. Pär Åhlström kicks off the discussion by presenting lean as a practice-based umbrella concept for business improvement, with flow efficiency at the core.

He further presents three pieces of advice for future lean research:

- Build research on existing definitions of lean, that include a possibility for falsification

- Be explicit and consistent regarding which level of analysis is applied when designing research on lean

- Focus not only on means but also on the ends (i.e., the reasons for implementing the various lean practices, rather than the practices themselves).

Lean as a socio-technical system (Danese)

Prof. Pamela Danese then presents lean as a socio-technical system, based on specific managerial routines that are guided by the scientific method.

Placing lean thinking at the nexus with digitalization, her advice for further lean research is to firstly understand how lean and industry 4.0 will integrate, and secondly adopt established theories from different fields (e.g., psychology, sociology or organizational studies) to investigate the impact of lean on job characteristics and workers’ wellbeing in gemba.

Lean as a unified theory? (Hines)

Next up is multiple Shingo Prize winner Prof. Peter Hines, who states that it is hard to see that there could ever be a unified theory of lean as there is still no real agreement as to what lean really is.

He does, however, provide the following areas for future lean research:

- We must continue to study the leading lean organizations to truly understand lean, as in many cases, practice is still ahead of theory

- We should consider the role of enterprise excellence in the enterprises of the future. What are the boundaries and how might it be best implemented, managed and sustained?

- We should also consider further integration of people aspects, as most lean practitioners still come from an operations or engineering background. HR and psychology professionals in particular, as well as academics, must learn more about lean in order to make greater contributions to it.

Lean as a business phenomenon (Netland)

Fellow Shingo-prize winner Prof. Torbjørn Netland presents lean as a business phenomenon and, in a call for more rigorous field research, suggests that we should study it as it evolves in practice to update and develop our lean knowledge base.

Regarding the term “lean”, Prof. Netland states that it is not so important, but does help to build a community of practice. As such, he suggests we should not get hung up on lean definitions, but rather study important relations (and questions) within this business phenomenon.

Furthermore, he suggests that current lean research frontiers appear to be its integration with new technologies, as well as the behavioural and cognitive aspects of lean.

Lean as the law of just-in-time (Thürer)

In the eyes of Prof. Matthias Thürer, lean is a theory that explains the law of just-in-time. However, he suggests that the theory is ill-developed, and recommends that future work explore how different forms of organizational change interact when improvement programs are implemented. He also suggests that as scholars, we should introduce a strategic component to lean, rather than continue to focus only on low-level operational processes.

Lean as a collection of theories (van Dun)

Prof. Desirée van Dun suggests that although lean is not a theory, it encompasses a variety of existing theories from different domains. Exploring a variety of lenses (including industrial psychology and organizational learning), Prof. van Dun explains why lean remains undertheorized, and indicates that future work should creatively assemble and refine potential lean theory rooted in different domains.

These include:

- organizational behaviour

- organizational development and change

- operations management

She also points out that abductive field research and engaged scholarship may help to refine and integrate the various existing theoretical lenses to build a lean meta-theory.

Lean as a meta-theory (Powell)

And it is precisely here where I lay my case! From my perspective as a lean pracademic with over fifteen years’ experience with a foot in both the academic and practitioner camps, I presented lean as a meta-theory. As a set-of theories that might lead organizations to create better business.

These theories are:

- a better production theory with the Toyota Production System (TPS)

- a better product development theory, with the Toyota Product- and Process Development system (TPPDS), including the chief engineer (shusa) system

- a better management theory with Toyota-style total quality control (TQC)

- a better economic theory with Hoshin Kanri (to better understand the business challenge(s) and scope the true potential for problem-solving); and

- the underlying psychological theory with the Kaizen mindset

My advice for future lean research is therefore to explore (in practice) how each of these theories can be better used to guide enterprise excellence through adopting lean as a holistic education system, with both customers and employees at the forefront. Lean cannot simply be reduced to a theory of efficiency for operations excellence. Lean thinking goes much further.

In that sense, I am very happy to share the same view as Prof. Rachna Shah, who clearly states that lean is not the TPS. Seeing lean simply as TPS applied to other companies fails to capture the true essence of lean. Rather, lean is an attempt to generalize and replicate lessons from Toyota in different company-, industry- and country contexts. And to replicate such lessons requires us to continually develop and build the lean education system, where we reflect over the way in which we teach, in addition to the way we learn.

As such, we should carefully consider the role of theory in future lean research. Afterall, as Dr. W. Edwards Deming said “Experience teaches nothing without theory. Without theory, there is no learning”.

The article can be found here: https://www.emerald.com/insight/content/doi/10.1108/IJOPM-06-2021-0408/full/html

0 comments on “Lean Research – Is Lean a Theory?”