Battery manufacturing spans both manual laboratory work and automated pilot line processing. In the early stages, materials are weighted, mixed, and characterized through workflows that often involve manual steps and offline measurements. Once prepared, these materials are transferred to the pilot line, where they are processed by automated equipment such as coaters and calendaring machines.

On the pilot line, machines operate with setpoints and dense sensor systems. Temperatures, pressures, speeds, and flow rates are continuously recorded, often with hundreds of parameters logged every second. This data is typically exchanged through OPC UA based networks and managed by software systems designed around machine communication and control. As a result, pilot line trials generate large volumes of detailed process data.

While this machine data is essential, it rarely explains outcomes on its own. It can show how equipment behaved during a trial, but it does not explain why one trial succeeded while another failed, or how the material changes affected the battery performance.

True clarity comes from connecting process data to the underlying material context.

Why material context is critical for trials

To interpret pilot line trials meaningfully, full visibility into the material’s history is required. This includes where the material originated, how it was formulated, which preparation steps were applied, and which recipe was used. Without this information, trial results are difficult to compare, and root cause analysis becomes unreliable.

In many pilot line setups, material preparation data and machine data are stored in separate systems. Laboratory workflows focus on flexibility and experimentation, while pilot line systems focus on automation and data collection. As a result, the connection between a trial and the exact material that was processed is often weak/missing or not machine-readable/accessible.

BATMACHINE and the role of Kadi4Mat

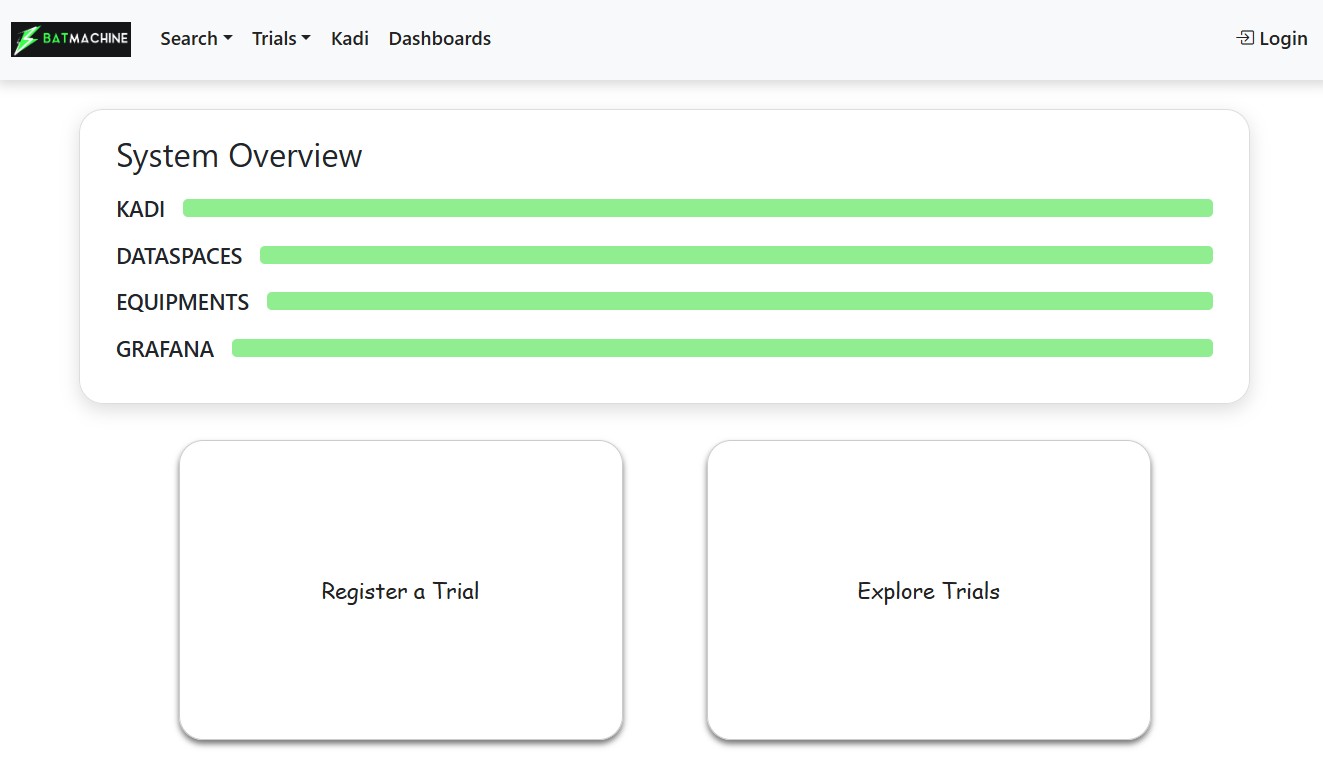

This challenge is addressed in the EU project BATMACHINE, which focuses on end-to-end data integration in battery pilot line environments. As described in a previous blog, BATMACHINE provides a shared dataspace (dashboard shown in Figure 2) that aggregates timeseries machine data, semantic knowledge graphs, visualization tools and process control interfaces, enabling consistent access to data across the pilot line.

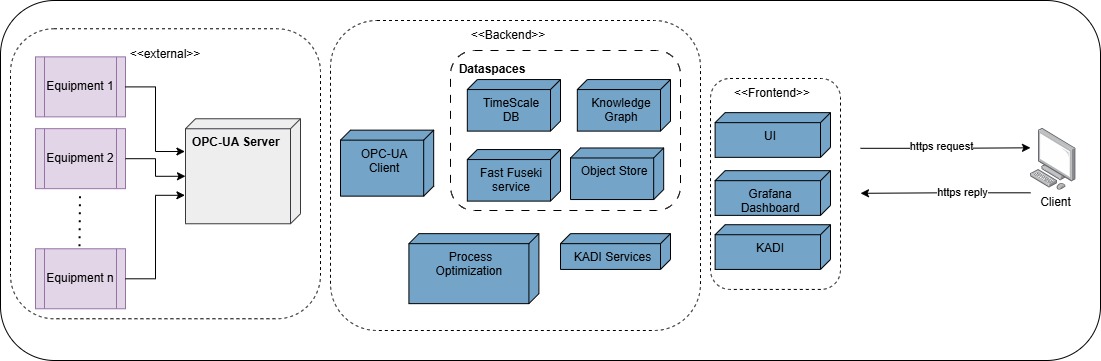

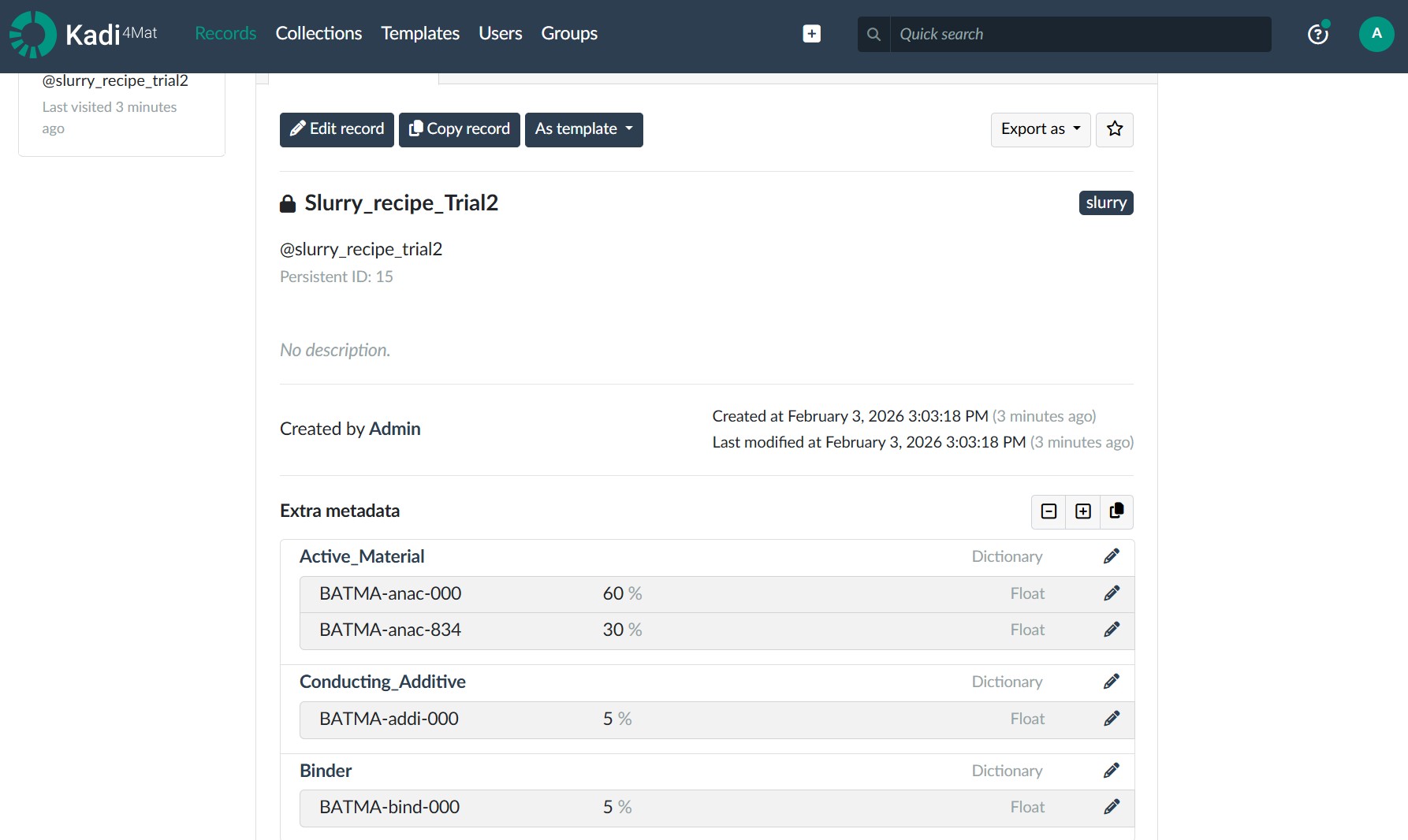

Within this architecture shown in Figure1, Kadi4Mat(Figure 3) is used as the system responsible for material management. It is a research data management tool, that can be used to track material provenance, thus providing the material metadata link that was missing earlier. Each pilot line trial is linked to a KADI4MAT recipe and material batch, ensuring that machine data is directly traceable to the underlying material preparation and process context.

Linking trials to recipes and material batches helps teams compare experiments based on real material changes. It makes learning from pilot line trials easier by clearly showing how material preparation affects the process and final cell performance. This supports faster optimization, improved reproducibility, and smoother scaleup from pilot to production using a data-driven approach.

Comments

No comments yet. Be the first to comment!