Have you ever heard of a heat battery? Or a cooling battery? If so, there is a good chance that you, like us at SINTEF, have an interest in new environmental technologies that is higher than the average. Heat and cooling batteries, also known as thermal batteries or thermal energy storage, have received undeservedly little attention as an enabling technology for a greener society, and that is something we intend to change.

When hearing the word “energy”, most people think of the electricity that keeps their lights on. Many are unaware that more than 50% of the energy we use in Norway and Europe actually goes to heating and cooling. Just as batteries provide flexibility to the power grid and the individual electricity consumer, thermal batteries can provide increased flexibility for heating and cooling. They can also relieve the power grid by reusing heat or shifting electricity consumption, depending on the energy systems around the battery.

Thermal batteries have significant advantages over their electrical counterparts when it comes to raw materials and ecological footprint. We hear a lot about critical raw materials and mining for metals used in electrical batteries, but thermal batteries rely merely on uncontroversial raw materials – often biomaterials, salts, or even very simple materials like stone and water.

We typically differentiate between sensible materials like stone and water, which get warmer the more energy you put into them, and phase change materials like biomaterials and salts, which me melt and solidify to store and retrieve heat. The SINTEF blog has previously had articles about how phase change materials can be used to make Norwegian and European industry greener and more efficient, or reduce emissions from the cruise industry. This article will take a closer look at how ordinary consumers can become more familiar with thermal batteries.

NTNU’s Gløshaugen campus in Trondheim is home to a unique and fascinating building that is commonly referred to as the ZEB building. ZEB stands for Zero Emission Building, and behind this acronym lies a range of technological refinements that contribute to maintaining a comfortable indoor climate while minimising the climate footprint. Among these technologies is a thermal storage system based on biowax as a phase change material, which has proven over a period of three years, as the first of its kind, to effectively buffer heat from heat pumps and the district heating system, thereby helping to reduce electricity consumption. For the last months, the daily excess production of solar energy from the building’s PV panels was stored every day in the form of heat, which then was delivered to the building when the sun was gone, providing pretty much free heating.

This same technology will soon be coming to an apartment block or office building near you. Based on the success of the ZEB building’s heat battery, two of SINTEF’s research scientists have started the spin-off company Cartesian, which can already offer heat and cooling batteries with a low climate footprint. We would love to see this technology adopted as quickly as possible, but its development shows even more promise.

Further development of thermal batteries

Through a collaborative project between Cartesian and SINTEF, we will continue to further develop the heat batteries to become more efficient and more flexible in how they integrate with the rest of the energy system. The work is happening in several areas: For example, we know that one of the biggest challenges with such heat batteries is getting the heat in and out of the battery quickly. How fast these processes occur depends on both the materials used and the geometry of the whole setup.

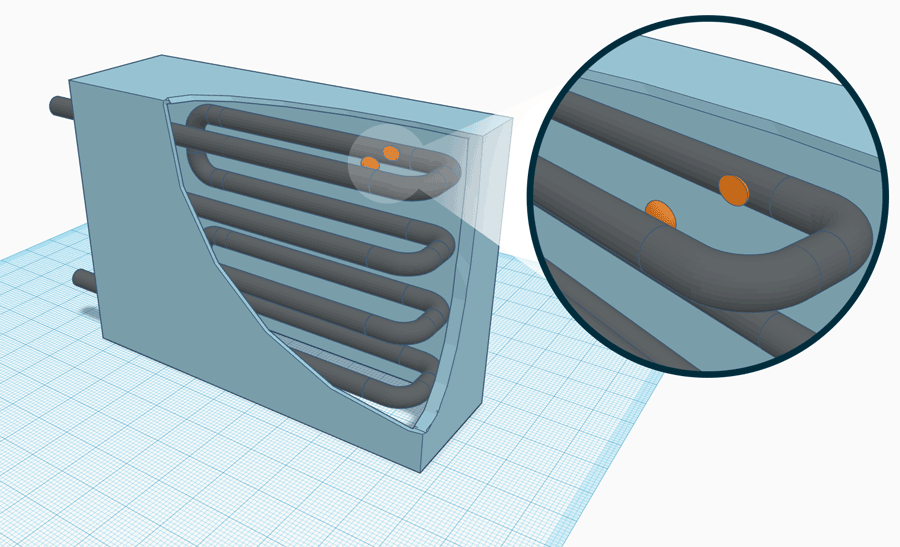

By addressing the latter and designing so-called heat exchangers that can transfer heat into and out of the storage more quickly, the battery will provide greater effect – that is, more heat per unit of time. Moreover, smart designs can not only increase efficiency but also reduce the total weight and volume of the storage, thereby reducing its footprint.

Another relevant area of research is the development of technology to know how much heat or cold the battery contains– in other words, its state of charge. How else can we know if the battery is about to run out, or if it is fully charged? Currently, indirect techniques are used to determine state of charge, such as keeping track of how much heat has been put into or taken out of the system. But after many cycles, this becomes more and more uncertain, which is why we need more direct ways to measure the remaining heat.

Since the thermal battery operates by storing heat in the transition between solid and liquid material, for example biowax, the challenge is to find methods to measure how much the biowax has melted or solidified. This might not sound difficult, though it is anything but simple, considering the rather complex geometry of the heat exchanger and biowax inside the tank.

Sensors can detect how much wax has melted in a specific area or along a specific line of sight inside the storage tank, but estimating this for the entire tank without filling it with sensors is no easy task. To solve this, we are working with Cartesian on improving both the sensors used and the processing of the sensor data.

The illustration above shows a thermal battery with its heat exchanger. Sensors (in orange) measure how much phase change material is melted in a specific area, to estimate how much energy is stored in the battery.

Thermal batteries soon in private homes

While thermal batteries are currently most useful in large buildings, where they can be integrated with a comprehensive energy system, there is also a type of heat battery that is more aimed at houses and apartments. In fact, it is easy to forget that thermal storage systems are already installed in most homes, in the form of hot water tanks. These are admittedly much simpler than heat batteries based on biowax or other phase change materials, which have an advantage over hot water tanks in that they can deliver heat at a specific temperature regardless of how much energy is left in the tank.

By comparison, if you want to store more energy in your hot water tank, you essentially have two options: either you increase the temperature of the water, or you increase the volume of the tank. SINTEF is therefore collaborating with hot water tank manufacturer Høiax, to see how phase change materials could be integrated into hot water tanks to reduce your electricity bill while maintaining or even improving the tank’s size and effectiveness. With a smart management of the tank, it can function as a flexible energy storage system, just like your electric car battery; charging when there is abundant or cheap electricity available, and thereby cutting both demand peaks and your electricity bill. It’s a triple win: for your wallet, for the power grid, and for the environment.

We believe that thermal batteries will eventually become as well-known as electrical batteries, through projects that bring thermal storage closer to people’s daily lives and helps them realise that heat and cold are important pieces of the larger energy puzzle. The above is just a snapshot of what we at SINTEF are working on to develop thermal storage for a variety of applications, for both industry and private use.

If you find, for example, that we have already talked too much about heat batteries and too little about cold batteries, check out this article: Cold thermal energy storage

If you’re interested in taking a deep dive into new, exciting materials for thermal batteries, you can read more about thermochemical materials here: Termokjemisk energilagring: Neste generasjons termiske batterier?

If you want to know more about our work, have questions or perhaps a good idea for a new application for thermal batteries, feel free to contact us or use the comment section below!

Comments

Great overview! This SINTEF post on thermal batteries is enlightening, well‑explained, and truly inspiring for smarter, greener energy use.