The cost and footprint of our future floating wind parks must come down, and being able to share mooring lines and anchors could be a game changer in that respect. But how do we test new shared mooring concepts that are too large to fit into existing hydrodynamic labs? By combining cyber- and physical spaces, in real-time!

What is shared mooring?

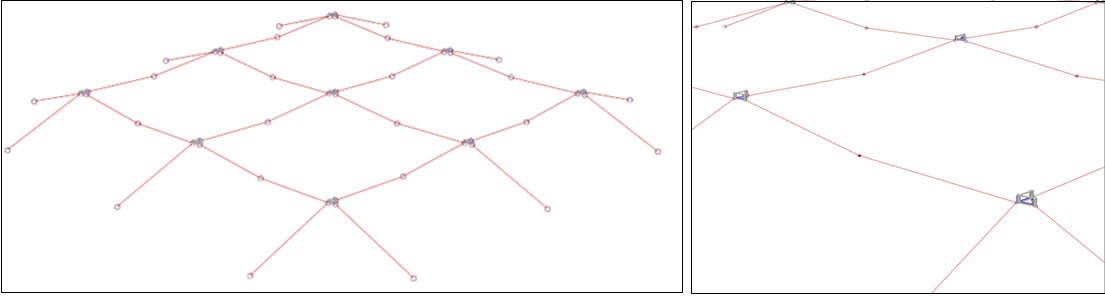

If mooring lines were shared between floaters in a floating wind park, the number of mooring components could be reduced drastically. In the example shown below, the number of anchors needed is more than halved compared to a farm with individually moored floaters. Less anchors to purchase, install, proof-load and recover, means significant cost and emissions savings.

But shared mooring systems also come with their drawbacks such as installation and maintenance challenges, and also: what is the dynamic behaviour of an interconnected park? And what if one of the lines breaks?

Understanding the behaviour of shared mooring systems

To address these questions, we had to improve our numerical models (simulating such wind parks is demanding), but also find out how to validate them against experiments. But how can you fit a whole floating wind park in an ocean basin?

Well, in practice, you can’t: the park shown below is more than 4 km wide, and to fit it in our (large! 80mx50m) ocean basin would require using a scale factor of about 1:100. This means small motions and very small forces in the lab – resulting in too big inaccuracies.

Cyber-physical testing of a 3×3 floating wind park, with shared mooring: a world first!

What we did was “simply” to make a numerical model (based on the best of our knowledge) containing 8 out of the 9 floaters. These 8 interconnected “cyber” floaters interacted in real-time with the 9th , which was the physical one, being tested in the basin. Loads resulting from the 8 were applied to the 9th using a cable-driven robot. The resulting motions of the 9th turbine was fed back to the simulator. This is what we call cyber-physical testing.

Using this technique, we simulated intact floating wind parks of various sizes, as well as line breakage scenarios. In the video below, you can see what happens when one of the downwind mooring line suddenly snaps.

This enables validating the predictions by our numerical models (did we capture resonances, did we model the damping correctly, etc.), and ultimately making more informed decisions about shared mooring systems.

Kudos to the team that made this possible!

Stay tuned

The CYBERLAB research project is a collaboration between Equinor, Mainstream, APL, Sevan SSP and Delmar Systems, NTNU, the University of Aarhus, and is headed by SINTEF Ocean. The floater used in our case study is the INO Windmoor 12MW open design.

More details about this project and our test campaign will be presented in conferences and journals in the near future. There should be a presentation about this in the upcoming Deepwind 2025 Conference (if abstract is accepted).

0 comments on “First hydrodynamic tests of a 3×3 floating wind park with shared mooring”