The advantage of industrial parks is that they provide possibilities for improving the utilization of waste heat.

Waste heat

Every industrial process produces energy which is not used in the process, in the form of waste heat. Instead of emitting this heat to the environment, as is frequently done today, it is preferable to use it within the process or in other industries. This will improve energy efficiency and hence reduce greenhouse gas emissions. The metallurgical industry in particular produces enormous amounts of excess heat that currently see limited application owing to the lack of users.

- SINTEF has expertice on Surplus heat utilization

The challenge and potential of low temperature waste heat

The utilization of high temperature waste heat is quite straightforward as it may be economically viable to generate electric power from it. That is unfortunately not the case for low temperature waste heat. There is therefore a need to come up with matchmaking strategies for co-location of businesses that could utilize some of the excess heat from large metal production plants.

Potential applications could include heating water, direct utilization in other processes in the plant, or for example fish farming, swimming pools, or greenhouses. This results in overall improved energy efficiency and, compared with upgrading or conversion to electric power, a higher energy utilization rate.

To date, low temperature waste heat is used internally and in several industry clusters as shown in the table below. The direct use of waste heat is the most economically viable but upgrading can often be profitable as well. The waste heat from dairy production can be upgraded internally for heating using heat pumps or cooling using absorption chillers or used externally for greenhouse heating. Hot water from the manganese production is furthermore used for smolt farming.

| Low temperature waste heat sources | Low temperature waste heat users |

| Waste heat, 35-40 °C, Tine | HTHP Tine can use heat from 90-180 °C. Upgrade for heating and cooling, Byrkjelo (200 kW cooling, 400 kW heating) and Frøya (430 kW heating) |

| Water at 35 °C, Tine, Kviamarka | Greenhouse, tomato and bell pepper |

| Water (75 °C) Glencore Mn production, Mo Industripark | Smolt farming |

“Industry dating” for waste heat utilization

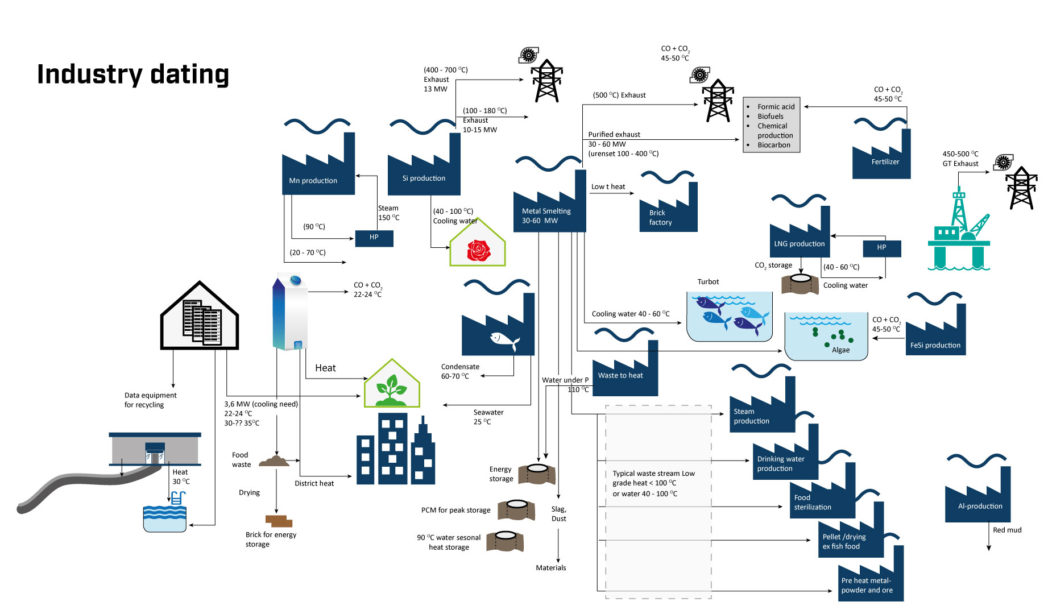

Aside from the existing utilization, how can we identify further users for low temperature waste energy streams, or in other words find suitable industry clusters? HighEFF introduced “industry dating” to identify potential matches between producers of low temperature waste energy and users of said energy. This approach allows the different industry sectors to talk to each other and identify business cases, in a manner similar to speed dating. Resulting synergies between the industrial sectors and ideas for low temperature waste heat integration can be found in the figure below.

Owing to the large number of different industrial sectors, the next step in this work is now a systematic approach which first calls for the identification of sources of low temperature waste heat, their energy content, and their temperature.

Secondly, potential users with a corresponding temperature requirement have to be identified. Furthermore, the location of the existing process with waste heat and the corresponding available space has an influence on which users are viable. The successful identification of potential inter-process energy integration will therefore be an important ongoing task for HighEFF.

Comments

No comments yet. Be the first to comment!