As we work towards operating cruise ships with zero emissions, it is important that we reduce the energy use of the hotel systems on board. We have modelled the hotel system of a cruise ship in a building simulation tool in order to evaluate various energy efficiency solutions, including passive measures, heat pumps and thermal energy storage. Passive measures utilise the building’s structure or materials to reduce energy consumption, for example by increasing or decreasing solar heat gains.

Reducing cruise ship emissions requires reduced hotel energy use

The International Maritime Organization (IMO) aims to reduce greenhouse gas emissions from international shipping by 50% by 2050 compared to 2008. In order to achieve this goal, it is necessary to reduce emissions from cruise ships. The focus of such efforts is often on the propulsion system of the cruise ships, for example, evaluating alternative fuels. However, on average, 40% of the energy use on board is related to the hotel system, and most related heating demands (space heating, tap water etc.) are currently met by using waste heat from the diesel engines. Many future cruise ships will instead use batteries or fuel cells, which provide very little waste heat. Therefore, in order to effectively reduce emissions, we must also reduce the energy use in the hotel systems on board. The aim of this study was to assess how various innovative energy-saving solutions can decrease the annual energy use of a cruise ship’s hotel system in a Nordic climate.

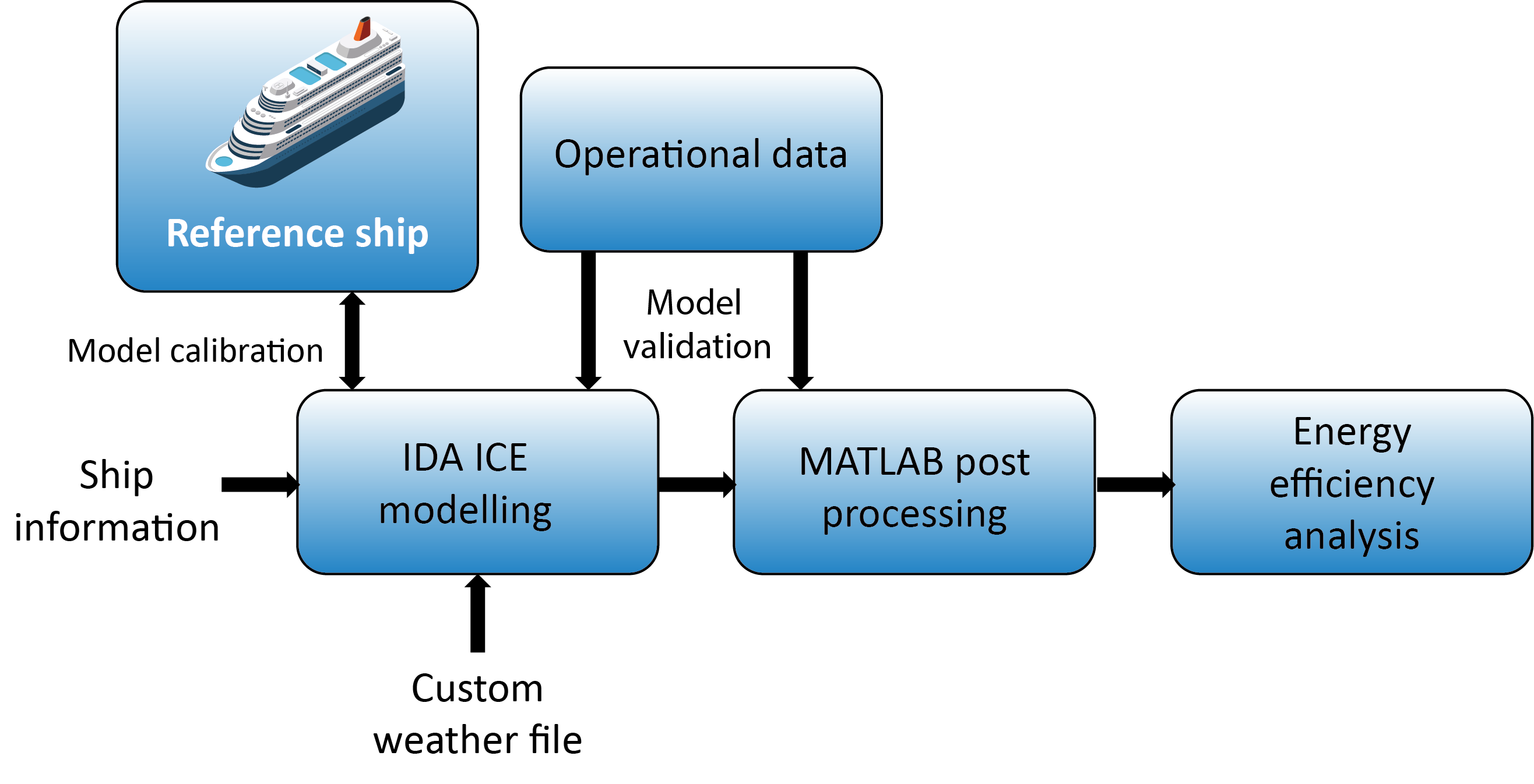

Adapting a building simulation tool to cruise ships

IDA Indoor Climate and Energy (IDA ICE) is a building simulation tool, traditionally used to simulate the energy use and indoor climate of buildings. Since cruise ships share many similarities with buildings, we decided to apply IDA ICE in a completely new way by modelling the hotel system of a cruise ship. However, there are also obvious differences between buildings and cruise ships, such as the ship’s engine system, which is used for both propulsion and supplying electricity and heat to the hotel system. This could not be easily implemented in IDA ICE and was therefore accounted for by running the results through a custom-made MATLAB script.

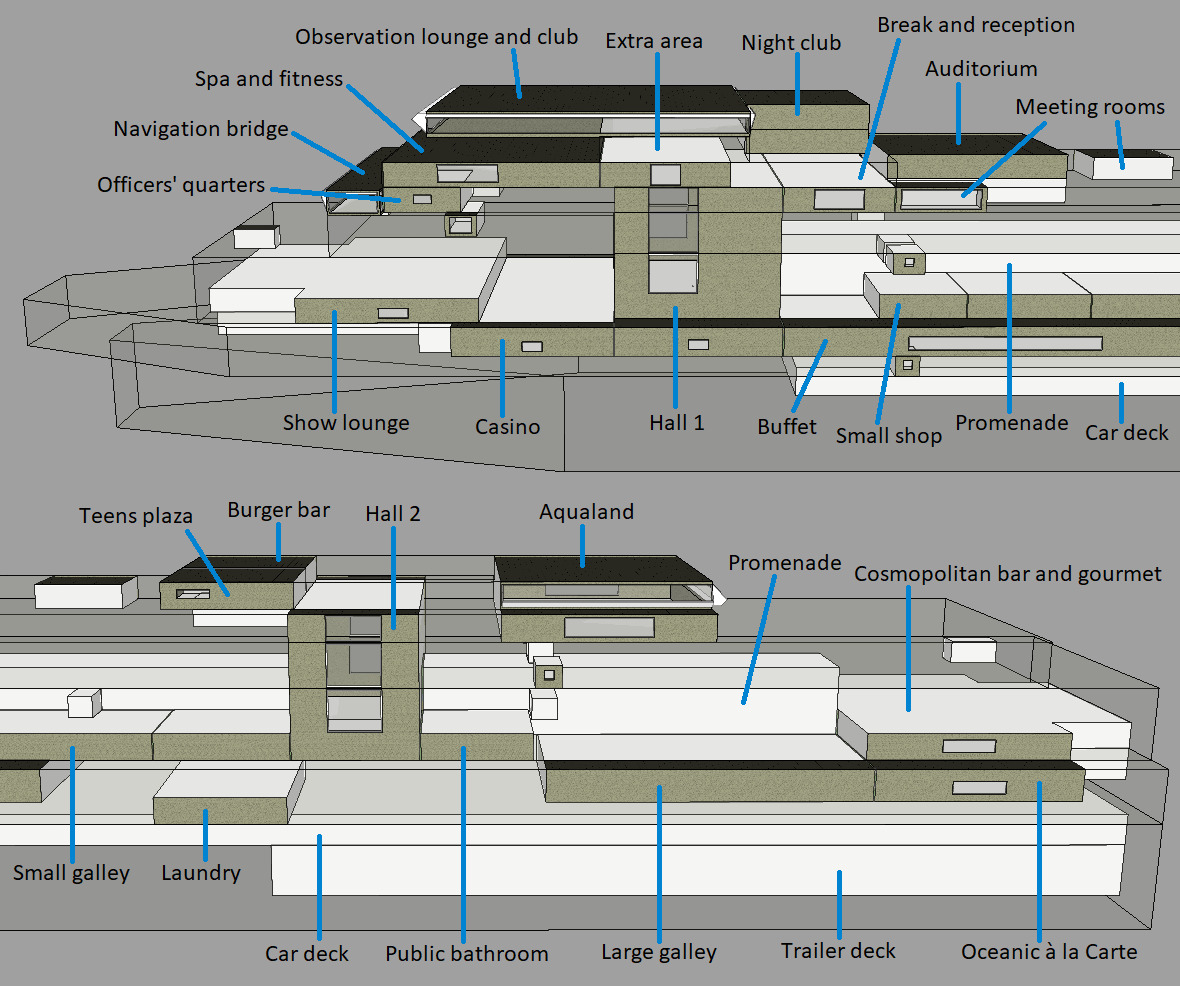

The model was based on the cruise ship Color Fantasy, which sails between Oslo, Norway and Kiel, Germany. We used design data from the ship to build the IDA ICE model, and we made a custom weather file by combining weather files from six different locations on the ship route. To reduce the modelling and simulation time, we modelled similar zones together as one zone, which were then multiplied.

We then added construction materials for the ship, and heat gains attributed to people, lighting and electrical equipment on board. Finally, we included systems for ventilating, heating and cooling cabins and public areas, and producing domestic hot water (DHW). We validated the results from IDA ICE and MATLAB by comparing them to the actual fuel consumption on Color Fantasy.

The ship model described above is considered the base case, representing the ship as it is today. Using the base case model, we evaluated the effectiveness of these energy efficiency solutions:

Case 1: Increasing insulation thickness in external constructions from 150 to 300 mm.

Case 2: Increasing the insulating capacity of all windows and reducing the size of large windows.

Case 3: Adding a 2 cm thick layer of phase change materials (PCM) in all walls, aiming to reduce fluctuations in indoor temperature and thereby reduce the cooling demand.

Case 4: Reducing heating during port stays and at night during winter.

Case 5: Turning off heating on the vehicle decks when in port.

Case 6: Increasing the efficiency of the ventilation heat recovery from 50% to 80%.

Case 7: Implementing variable air volume (VAV) ventilation, controlled by motion sensors or temperature and CO2 sensors.

Case 8: Installing an air-to-water heat pump with a heating capacity of 3.1 MW.

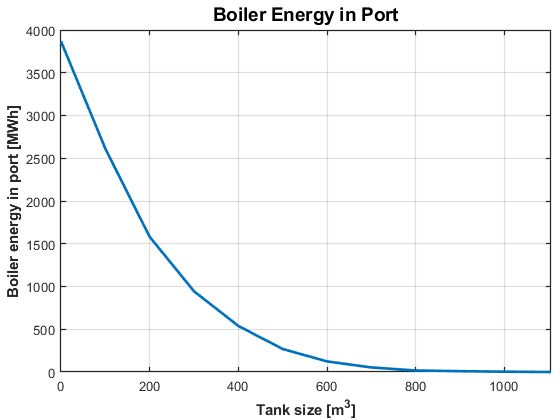

Using the MATLAB script, we also evaluated the use of a hot water storage tank to store waste heat recovered from the engines to be used later when the ship is in port. In this way, we can reduce the local pollution caused by the current use of fuel boilers for heating.

Air-to-water heat pump saved the most energy

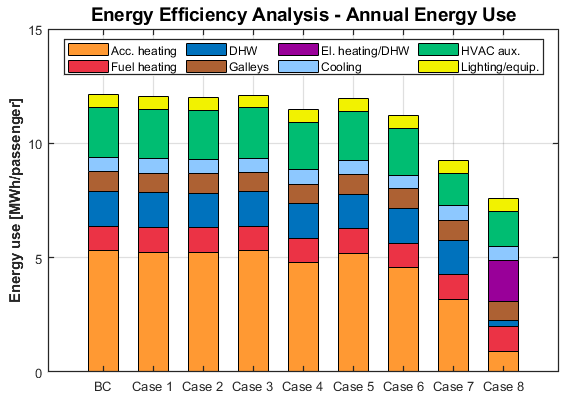

The base case had a total annual energy use of 54.7 MWh/passenger, with the hotel system accounting for 20% (11.0 MWh/passenger). This is similar to the energy use per guest in Norwegian and Swedish hotels.

The figure below shows the energy use, excluding propulsion, for the different energy efficiency scenarios and the base case (BC). “Acc. heating” refers to the accommodation heating and vehicle deck heating supplied by fuel boilers and engine heat recovery. “El. heating/DHW” refers to the electricity used by the heat pump in Case 8. “HVAC aux.” includes the electricity used by fans and pumps in the heating, ventilation and air conditioning (HVAC) systems.

The three passive measures (Cases 1-3) reduced the annual energy use by less than 1%. The improved insulating capacities had a limited impact on the heating demand, as much more heat is lost through the ventilation system than through the external facades of the ship. PCM layers in walls were ineffective due to small variations in indoor temperature during the summer.

Case 4, with heating turned down in port and at night during winter, reduced the energy use by 5.3%. These energy savings could be increased by expanding the solution to include the summer months. In Case 5, where the vehicle deck heating was turned off in port, the energy use was reduced by 1.4%. An alternative option could be to lower the heating setpoint temperature on the vehicle decks by 1-2 degrees at all times.

In Case 6, with improved ventilation heat recovery, the heating demand was reduced by 14%, the cooling demand by 2%, and the electricity use for HVAC fans and pumps by 8%. For Case 7, with VAV ventilation, the reduced ventilation led to a 40% reduction in heating demand, a 9% increase in cooling demand, and a 37% reduction in energy use for fans and pumps. Cases 6 and 7 were relatively effective due to the large amount of heat that is lost through the ventilation system.

Case 8, with a heat pump, showed the largest energy savings of all the solutions and is the only case that resulted in reduced energy use for DHW. The total energy use for DHW and accommodation heating, including electricity for the heat pump, was reduced by 57% compared to the base case. Excluding electricity use, the energy use for accommodation heating was reduced by 83%. The electricity use for fans and pumps was reduced by 30%, while the total electricity demand was increased by 33%.

Hot water storage tanks could be used to cover heating demands in port

Finally, we examined a case with a hot water storage tank. In order to cover all the heating demands in port, the tank size had to be 1105 m3. In this case, the tank was optimised to reduce the use of boilers in port, which meant that it sometimes had to be charged by boilers during sea passage in addition to being charged with waste heat recovered from the engines. Despite this, the 1105 m3 tank still managed to reduce the amount of heat delivered from boilers by 14%.

For the majority of ships, a tank of 1105 m3 is unreasonably large, and we therefore investigated the effect of using a smaller tank. The boilers’ annual heat supply in port can also be significantly reduced when using a smaller tank, which would therefore be a more reasonable alternative, unless it is crucial to ensure zero emissions in port. An electric boiler running on shore power could also be used in combination with a small tank in order to achieve zero emissions.

Reducing energy use, costs and emissions for existing and future cruise ships

To make sure that the IDA ICE model produces accurate results for all the energy users on the cruise ship, it would be useful to collect more data from real operation and validate the model in more detail. This would open the door for using the model to design future low-emission cruise ships.

Simply by changing the weather file, the model can be used to investigate energy-saving solutions for similar cruise ships sailing in any climate zone. In combination with a profitability analysis, we could use the model to find the best solutions that reduce energy use, greenhouse gas emissions and operational costs, both for existing cruise ships and newbuilds!

This blog post is based on the scientific article “Energy use and energy efficiency in cruise ship hotel systems in a Nordic climate” by August Brækken (SINTEF), Cecilia Gabrielii (SINTEF) and Natasa Nord (NTNU). The presented research was conducted within the projects “LowPass – Future low-emission passenger ships” and “CruiZE – Cruising towards Zero Emissions”.

0 comments on “Preparing for zero-emission buildings at sea”