Subsea “hybrid cables” have been the subject of much debate in Norway these past few months, but what are they exactly and what makes them such a hot topic of discussion?

The word “hybrid” usually means that two different things are combined. Hybrid cars, for example, can run on both petrol and electricity. But the “hybrid kabler” that are talked about so much in Norway these days are hybrid in another sense. They transmit only power.

In English, “hybrid cable” typically refers to cables that serve two functions, such as transmitting both data and power. For the purposes of this article, “hybrid cable” will refer to the hybrid kabler that have been the subject of debate in Norway these past few months. These cables are subsea cables that transmit only power.

In short, the cables being referred to as hybrid cables in Norway right now are simply DC cables. These cables transmit power in the form of direct current (DC), as opposed to alternating current (AC). What differentiates a hybrid cable from a subsea interconnector joining two countries or regions is that the hybrid cable has, in addition, a point of production or consumption somewhere in between. To be able to send and receive power, the DC cable has to be connected to a converter station. But let us get back to that later; first we must explain why the need for hybrid cables arises.

Electrification requires us to generate more power

The oil and gas industry and the mining industry account together for almost half of all Norwegian greenhouse gas emissions. These are energy-intensive sectors and there is a broad political consensus that the electrification of these and other industries is the most important key for Norway to reach its climate targets. But even with our access to electricity from existing hydro and wind power, we need to increase production substantially to achieve this transformation.

In our opinion, building offshore wind power is one of the most important measures that can be taken to ensure a sufficient production of renewable energy. Many of the solutions that need to be implemented are currently being developed at the NorthWind research centre and at the LowEmission research centre. The technical potential for offshore wind is enormous. According to the International Energy Agency (IEA), it can meet the world’s electricity demand 18 times over.

For offshore wind power to be used by both the oil and gas industry and land-based industry, we need cables to transmit the electricity to where it’s needed. This is where hybrid cables come in, as well as various other solutions to transport energy over long distances.

The electricity must be stored or used

If wind farms are to supply electricity to offshore platforms, the electricity will have to be either used immediately or stored. One typical way to store electrical energy is by using a battery. But batteries are large, heavy and it would be expensive to install them on offshore platforms that have been optimised and certified for the loads that they are bearing today. This means that distributing the power efficiently is a better solution.

Read more about our research on emissions reductions in oil and gas at the LowEmission research centre

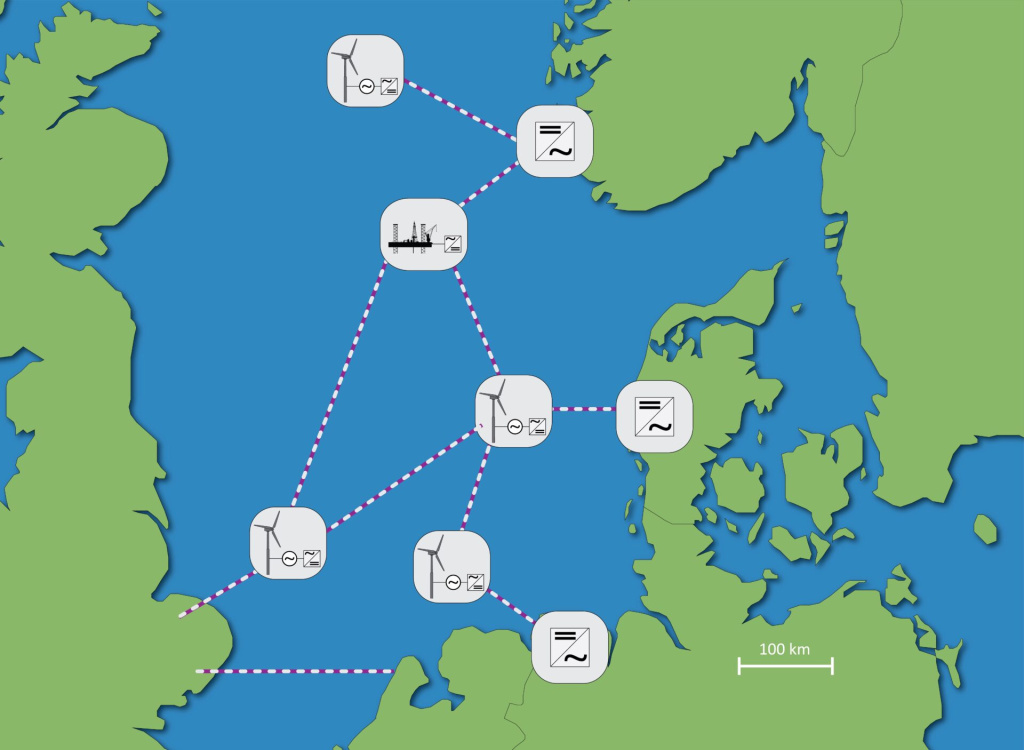

One area that’s earmarked for offshore wind development by the Norwegian government is Sørlige Nordsjø II, which lies approximately at an equal distance from the shores of Norway, the UK and continental Europe. If cables can be run to connect this point to all three markets, the potential for profitability of a future offshore wind farm at this location increases, since it will be connected to a greater number of potential consumers of the electricity being generated.

We will not get into the political choices that can be made about regulating how much electricity should be used locally, and how much should be sold abroad. But the fact is that as long as we don’t store the power generated by wind farms, it has to be sent where it can be used if it’s not going to go to waste. The renewable energy we get through hydropower today is easy to control, through the management of the water reservoirs. Hydropower used together with wind power gives us a robust energy supply, by enabling us to use wind power when the wind is blowing, and switch to hydropower when the wind stops. In that way, the water reservoirs become less vulnerable to periods of drought.

Read more: The North Sea as a springboard for the green transition

Radial connections or hybrid connections

There are two ways to connect an offshore wind farm to the market: through a radial connection or through a hybrid connection. A radial connection is a cable that links the offshore wind farm to a point on the main power grid. As an example, an offshore wind farm in Norwegian waters linked by means of a radial connection would be sending its power to the Norwegian power grid.

We can also imagine a scenario in which offshore wind farms would be connected to oil and gas installations on the Norwegian continental shelf. These wind farms could operate either in a completely isolated system, together with the oil and gas platforms, or have a connection to the mainland. In an isolated system, the oil and gas platform’s gas turbines would have to be on standby continuously, as a backup solution against wind variations. But if you add a connection to the mainland, the gas turbines are suddenly not needed anymore. If the wind farm is large enough, there could even be a surplus of power that would be sent ashore.

A hybrid connection connects the offshore wind farm to two regions (for example Norway and the United Kingdom). So when we say “hybrid cable”, what we really mean is “hybrid connection.”

Long distances require high tension and direct current

How far a wind farm is from shore determines the type of cable that should be used. For instance, the Utsira Nord area, earmarked for offshore wind development by the Norwegian government, is relatively close to shore and can be connected with an alternating current cable (AC).

Larger wind farms located further offshore than 100 km will typically need to be connected to land with a high voltage direct current cable (also known as a HVDC connection). This reduces transmission losses and has other technical advantages, but it requires installing expensive HVDC substations both at sea and on land.

AC: alternating current

Alternating current changes directions periodically, such that on average, there is as much current going in either direction on a transmission line. Before it is delivered to the consumer, the electrical energy goes through a transformer, which reduces the voltage to 230 V.

DC: direct current

Direct current does not switch direction and flows at a constant rate. This results in minimal transmission losses and large transmission capacity.

HVDC: High-Voltage Direct Current

High-Voltage Direct Current refers to a transmission system that uses DC current to transmit power at a high voltage. Alternating current gets transformed to direct current at the point of entry, and then transformed back again to alternating current upon exit, before being sent to the power grid.

Pros and cons of AC and DC

AC cables transmit alternating current and have significant losses over long distances. We have the technology to reduce these losses through installing series compensation stations along the line. But this means breaking up the cable at regular intervals, which is expensive and technically challenging. An advantage of AC is that it makes it relatively simpler to interrupt the current, and thereby makes it easier to isolate faults so that they don’t create a domino effect on the grid – these kinds of safeguards are crucial to grids. With DC, interrupting the current is more difficult, and more research and development is needed to realise a DC grid. The fact that AC does not require transformers at either end of the cable is another advantage, while DC can transmit larger amounts of energy, over longer distances.

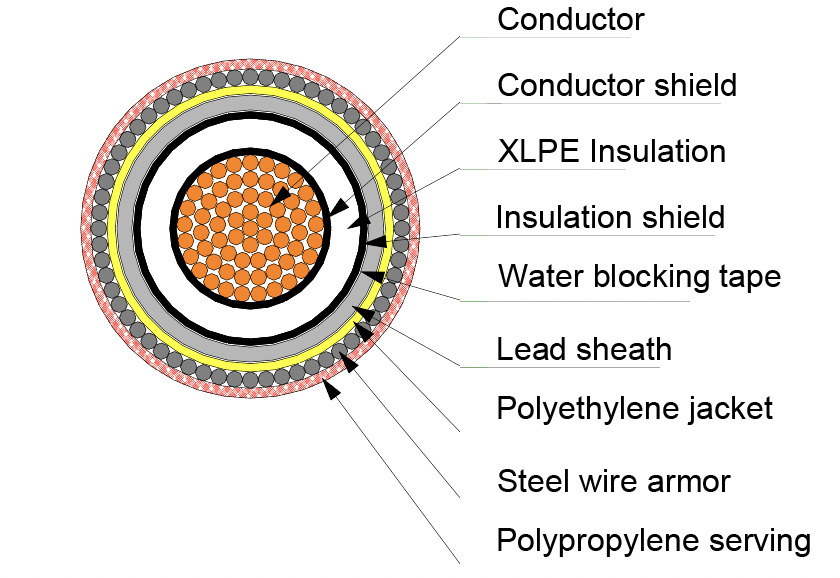

Both AC and DC subsea cables have a relatively simple build, consisting of a conductor, an insulation system, a water barrier (typically a layer of lead) and an external armouring, designed to provide mechanical protection during installation, as well as protection against external elements. For DC cables, the insulation system consists of either paper impregnated with a very viscous oil (mass impregnated cable), or plastic (cross-linked polyethylene). These types of cables have to meet high standards, and there have been rapid improvements in their transmission capacity over the last few decades.

High voltage subsea cables: reducing costs by simplifying design

Cables are typically the most expensive component of the electrical infrastructure needed to electrify oil and gas installations, or to connect offshore wind farms to the mainland. Researching new technological solutions therefore offers a promising potential to reduce costs without compromising on reliability.

One such solution would be to remove the lead layer that is currently used to prevent water ingress inside the insulation. This would constitute a more cost-effective design, reduce installation costs (because the cables would be lighter) and enable the cables to better withstand dynamic mechanical stresses (the lead sheath can easily crack when the cable is moved around a lot). The disadvantage of removing the lead layer is that water can come in the insulation system and cause degradation over time, through the growth of what is called water trees. Water trees are a dense network of extremely small water-filled channels. They slowly reduce the reliability of AC cables and can lead to breakdowns. Water trees have also been observed on DC cables, but the effects of water ingress in such cables is not as well known, so there is uncertainty regarding the extent to which water trees reduce the life expectancy of DC cable systems.

Electrification is relevant for all countries

To exploit the immense potential of offshore wind, and get the necessary energy for the green transition, we depend on a well-functioning infrastructure. Subsea cables are a central part of this infrastructure. The main focus of cable manufacturers and their partners (including SINTEF) is to develop better cables that can transmit even more energy than the ones in existence today.

Another important driving force in the development of tomorrow’s subsea cables is the need to use more sustainable solutions to make all the life stages of the cable more environmentally-friendly. This includes, naturally, looking at alternative materials to ensure that the components of a cable can be reused or recycled after its decommissioning.

The debate surrounding hybrid cables is ultimately about the balance between Norway being self-sufficient and contributing to the European transition towards a sustainable society. By connecting our national grid and offshore wind farms with hybrid cables, we lay the groundwork for future energy trading with other markets.

Comments

Forvirrende og unødvendig begrep – hybridkabel.

I den senere tiden har et nytt begrep dukket opp i diskusjonen om utbygging av offshore vindkraft og de kablene som skal bygges for disse anleggene; nemlig ‘hybridkabel’. Forklaringen på begrepet er ‘kabel/kabler fra en vindpark mot to ulike land’, f.eks. mot Norge og UK (eller Danmark) for en vindpark i Nordsjøen. Begrepet promoteres (dessverre) av både fagmiljøene (f.eks. Statnett og SINTEF), og journalister og politikere.

Dette er et litt merkelig begrep og ganske forvirrende. Det samme gjelder alternativet som av en eller annen grunn kalles ‘radialkabel’.

Hybridkabel har alltid, i alle fall mens jeg jobbet i kabelbransjen, betydd en kabel med to ulike bruksområder; f.eks. en telekomkabel med både kobberpar og optiske fibre, eller en kraftkabel med integrert fiberkabelement. Dette stemmer godt med begrepet ‘hybrid’ som noe ‘som er framkommet ved krysning eller sammensetning av flere elementer’ (Bokmålsordboka); da med ‘elementer’ tradisjonelt i betydningen plante- eller dyrearter. Vi kjenner begrepet også innenfor bil&motor der en hybridbil har to ulike motortyper (el og forbrenningsmotor) og her gir det god mening.

Men det nye begrepet slik dette er forklart (av SINTEF her) er på ingen måte analogt med denne tradisjonelle forståelsen. I tillegg vil jo begrepet bli enda mer forvirrende hvis kablene får integrerte fiberkabelementer, noe til trolig vil få (for telekommunikasjon eller temperaturovervåking).

Det man forsøker å forklare med begrepet er jo – som i artikkelen her – strukturen i kabelnettet, dvs. som ‘kabler i to ulike retninger’. En kabel kun til ett sted, f.eks. Norge, kalles da en ‘radial’ (Bokmålsordboka: ‘som hører til, faller sammen med en radius, stråleformet’) som heller ikke gir noen mening som kabeltype og alternativ til ‘hybridkabel’, men derimot også kan si noe om strukturen i nettet.

Jeg har de senere årene vært involvert i mange offshore windfarms i UK og kablene til land er utelukkende kalt ‘windfarm export cable’; det gir mening fordi de eksporterer kraften (energien) fra vindparken inn til land. Et forvirrende element her blir jo da at ‘eksportkabel’ i manges øyne i dag forstås som en utenlandskabel som brukes til å ‘eksportere vannkraften vår’, så da blir det viktig å kalle utenlandskablene for ‘mellomlandskabler’ eller ‘interconnector cables’ som er de tradisjonelle begrepene.

Et kjapt søk på nettet (DuckDuckGo) viser at de fleste av de få som bruker ‘hybridkabel’ eller ‘hybrid cable’ i den nye betydningen er norske medier (NRK, Nationen, SINTEF m.fl.), så vi må kunne si at dette er et typisk norsk fenomen. Vi som er fagfolk på området kan jo håpe på at begrepet dør ut så snart som mulig, men siden media og politikere nå har begynt å bruke det med støtte fra fagfolkene i Statnett så er vel det et fåfengt håp.

Men; ingen kritikk uten alternative forslag: En bedre beskrivelse – og som samsvarer med tradisjonelle begreper – vil være f.eks. ‘vindparken vil få eksportkabler både til Norge og UK’ (hybridkabel), eller ‘vindparken vil få eksportkabel bare til Norge’ (radialkabel). Kablene i seg selv er ikke forskjellig fra dagens kabeltyper.

Dette omfattende og kompliserte fagområdet er vanskelig å forstå for mange allerede – noe alle medieoppslag og debatter klart viser oss – så vi som er fagfolk bør bidra til folkeopplysningen ved å bruke lettforståelige og ikke-forvirrende begreper.

Sverre K. Myren

teknolog/elektroingeniør

Oslo

(innholdet ble foreslått som debattinnlegg i Teknisk Ukeblad men det ble – etter først positiv tilbakemelding – ansett som uinteressant av redaktøren uten nærmere forklaring eller tilbakemelding…)