- Guest blogger: Juliana Monteiro, TNO

Valuable products such as plastics and fuels can be derived from CO2, in a circular manner, as a replacement for fossil fuels. Following this line of thinking, CCU appears to be the silver lining in the climate change cloud.

The stable CO2 molecule and the climate challenge

To make an impact on the climate, the amounts of CO2 to be avoided are massive. In the cement industry alone, a target of capturing and storing 552 MtCO2 per year by 2050 was recently proposed by IEA and CSI.

Additionally, CO2 is a rather stable molecule. This means that for CO2 to react and be transformed into high energy products such as fuels, a lot of energy must be provided. Therefore the CO2 utilization reactions normally take place at elevated pressures and temperatures, and using high energy reactants such as hydrogen.

Large quantities of CO2-free renewable hydrogen will need large quantities of renewable power

CO2-free renewable hydrogen may be produced from water, using wind electricity to power electrolysers. Safely storing and distributing hydrogen is a challenging task. By reacting CO2 and hydrogen, drop-in fuels like ethanol or gasoline can be manufactured. However, about 1GW would be needed to produce the hydrogen required to convert 90% of the CO2 emitted from an average cement plant to ethanol. For the sake of comparison: this is the nameplate capacity of the Fosen Vind complex in Norway, comprising 278 wind turbines – a project with expected cost of 1.1 billion euros.

Of course, building a dedicated Fosen Vind per cement plant is out of question. However, in a scenario with multiple renewable energy sources (e.g. solar and wave power) integrated in the grid, excess power is expected to be available periodically, not at the 1 GW scale, but a scenario in which dozens of MW become available is likely. This power can be used to generate relatively low cost renewable hydrogen, which can be reacted with CO2 to generate fuels.

CCUS – a viable compromise for CCU and CCS

Therefore, the extent to which CO2 may or should be utilized will depend on multiple factors such as the market size of the final product, the availability of renewable feedstock, and of course on the economic and environmental impacts of the technology chosen. Taking these factors into consideration, it is unlikely that CCU could ever completely replace CCS. Instead, the combination between the two approaches – CCUS – may be the optimal solution. For large scale applications such as cement plants, most of the CO2 will need to be sequestrated, but utilization of a fraction up to 10% of the CO2 may be beneficial.

In deliverable 5.1 of the Horizon2020 CEMCAP project we have evaluated how the addition of a CO2 utilization component to the CCS chain –thus making it a CCUS chain – affects the CO2 avoidance costs. The report shows that the outcome can be either positive (lowering the cost of CO2 and even turning the full CCUS chain into a profitable business) or negative, depending on the final product characteristics.

Amongst the main characteristics affecting the CCUS chain performance are the product price, the market size, and the CO2 avoidance of the technological route. While this performance evaluation has to be made case by case, the routes described in D5.1 may serve as guidance for the evaluation of similar products.

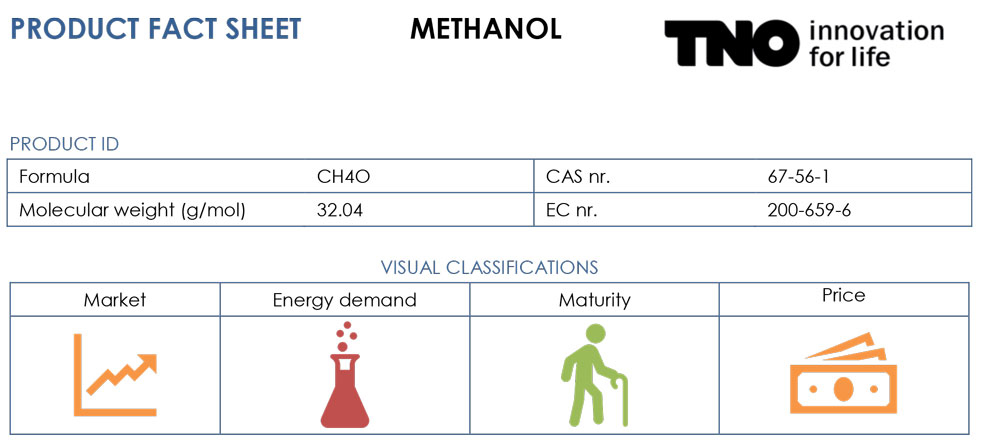

CO2 product fact sheets

Given the large number of alternatives of CO2-based products, we have collected some key information on each product in “CO2 product fact sheets” (Links below), intended to serve as a guiding instrument when evaluating a utilization route. By presenting key factors such as market size, energy demand, technology maturity level and price of various CO2 derived products, the fact sheets give a quick overview of the possible products and how they are related to the alternatives.

The collection of CO2 fact sheets published in the CEMCAP website is extensive, but not exhaustive. Beyond CEMCAP, it is TNO’s intention to update the fact sheets on a regular basis, to provide as complete as possible figures in supporting the evaluation of CCUS routes.

Comments

No comments yet. Be the first to comment!