“With high-density and high-frequency recordings of both pressure and temperature, we can put transient multiphase flow models to the test. This will help us deploy efficient and safe CO2-transportation systems,” says Munkejord.

The safety of CO2 transport

CO2 capture, transport and storage (CCS) is recognized as a key climate change mitigation technology, both in the short-term before fossil fuel use is reduced and in the long-term to mitigate emissions inherent in industrial processes.

If and when CCS is implemented at scale, several gigatonnes of CO2 will have to be transported via pipeline to the storage sites in order to meet the challenging climate targets of 2050. This requires a better understanding of processes that may not be covered by existing engineering tools and methods.

A better understanding of depressurization in CO2 pipelines

One of those processes is the depressurization of the CO2 pipelines. To better understand the process, accurate transient flow models capturing the occurrence of gas, liquid and solid CO2 are needed. These in turn rely on experimental validation.

The new article published in Energy presents the new experimental facility designed to capture pressure and temperature during the depressurization of CO2 and CO2-rich mixtures in a tube at high spatial and temporal resolution.

Lead author Svend Tollak Munkejord says the article’s three main contributions are:

- The presentation of new depressurization experiments for CO2 in a tube. Accurate and dense measurements of pressure and temperature are reported. Such temperature measurements have not been reported before.

- The data used in the study is available openly via Zenodo. The authors believe that such a dataset has never before been made openly available.

- The experimental data are compared to calculations performed using a homogeneous equilibrium model (HEM), which is well known and well defined. This allows interpretation and discussion of the results against a firm reference.

“Existing models work for some of the observations, but not for all. We have just employed a PhD candidate in the NCCS centre who will delve into these challenges,” says Munkejord.

Successful demonstration of the new ECCSEL lab

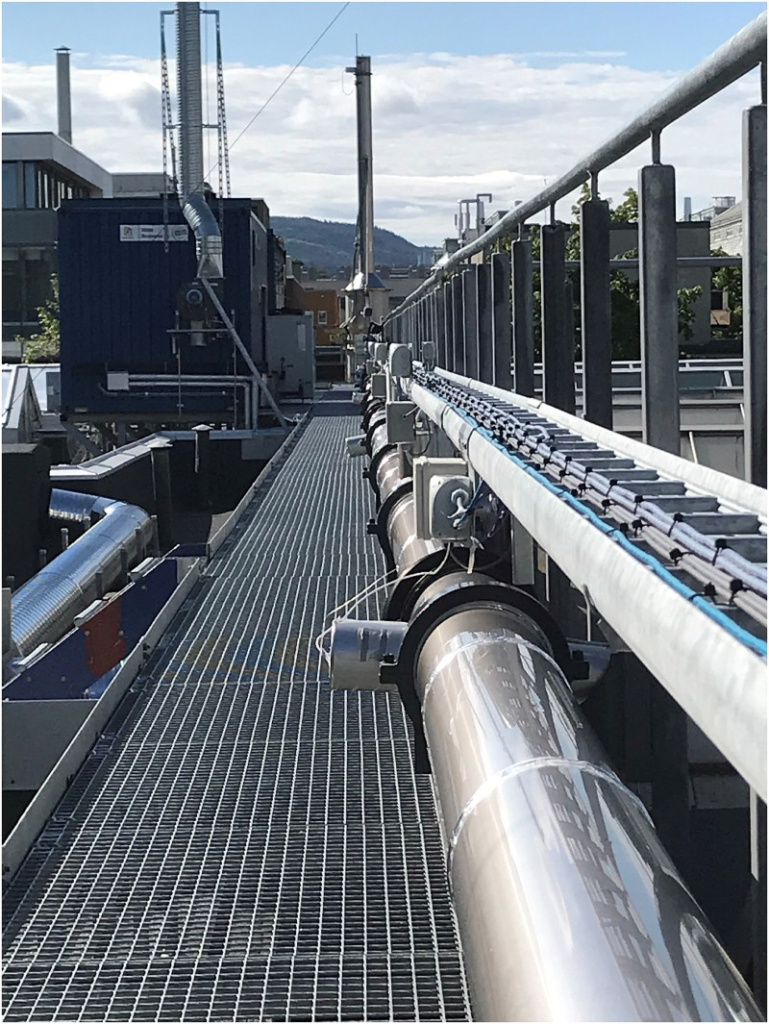

The study used the new depressurization facility DEPRESS in Trondheim, Norway. Part of the European CCS Laboratory Infrastructure (ECCSEL), DEPRESS can measure the transient multiphase flow of CO2 mixtures to see what happens during start-up, shut-down, depressurization, and varying CO2 supply.

Consisting of an interconnected depressurization pipe and tank, DEPRESS supports the development and validation of physics-based pipeline integrity models and flow models.

The pipe has dense instrumentation for both pressure and temperature. There are several temperature sensors that can give an indication of the flow regime. Care has been taken in the design of the facility to allow the upscaling of models, and to achieve full opening without inducing pressure disturbances.

DEPRESS is one of several ECCSEL facilities based in Trondheim, Norway. Within the initial 5 European founding Member countries of ECCSEL (France, Italy, the Netherlands, UK and Norway), 21 service providers offer open access to more than 79 world class CCS research facilities across Europe.

Comments

No comments yet. Be the first to comment!