Carbon Capture and Storage (CCS) is widely accepted as one of the viable solutions to the greenhouse gas problem. An important part of CCS is underground storage of the captured CO2. In order for an underground reservoir to serve as a long-term CO2 repository, leakage of the stored gas must be prevented. It should be noted that CO2 storage is safe with little leakage today. But there is still room for improvement in the way we use cement to seal off wells.

In this blogpost we look at how long the cement sheath in the well construction should be to ensure there is no leakage, based on a study conducted in The Norwegian CCS Research Centre (NCCS).

Potential escape routes and CO2 leakage prevention

There are several potential escape routes for CO2 stored in geological strata. One of these routes is through the injection wells themselves. If an injection well is poorly cemented, leakage of CO2 might take place already during the injection.

Learn more about CCS

Join our newsletter to stay updated with all the latest research results and news from NCCS: The Norwegian CCS Research Centre.

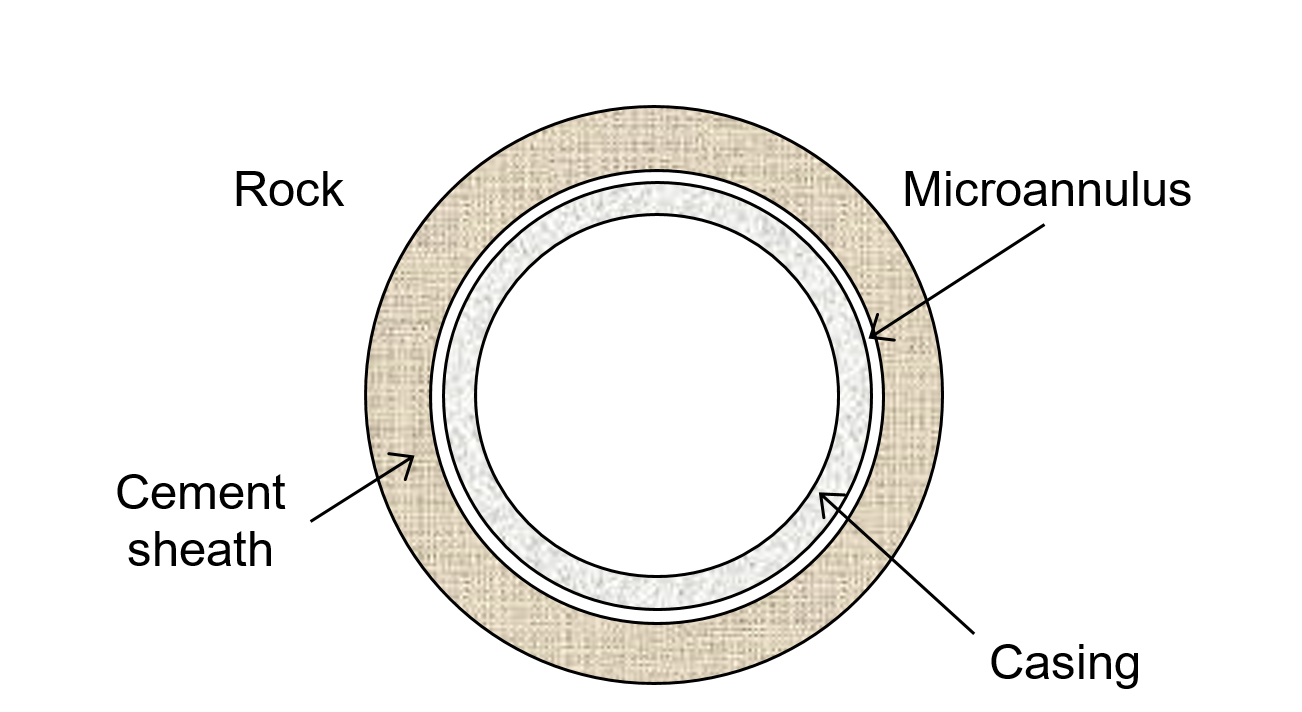

For instance, a thin uncemented channel (called microannulus) running along the interface between the casing and the cement sheath may serve as an escape path (Figure below). The gap (also called aperture) of such a microannulus could be just a few thousandth of a millimeter. Microannulus could be caused by a poorly executed cementing job. It could also be created later, e.g. when the well is subjected to heating-cooling cycles during CO2 injection. In any event, a microannulus is bad news since it creates a flow path along the well that was supposed to be tight.

The importance of high-quality well cementing has been recognised for a long time not only in CCS, but also in geothermal and oil & gas sectors. Efforts are made to improve cement compositions and cementing practices. Today’s well cementing is not what it used to be 30 years ago. But some challenges still remain. One of these challenges, ubiquitous in geosciences, is uncertainty.

A challenge in well construction is uncertainty

Information about downhole conditions is limited; there is no direct access, geological formations are heterogeneous, etc. This inherent uncertainty has a bearing on leakage predictions and risk analysis. In a recently published article, scientists from NCCS recognise this uncertainty and use a stochastic approach to gain a deeper insight into well integrity in CCS. In particular, they address the following question:

Is it possible to assign a minimum length of cement sheath that would ensure that leakage does not occur in e.g. 95 % of injection wells?

If the answer to this question is “yes”, then preventing leakage should be easy: the regulator just needs to make it mandatory to cement wells up to a certain length, and the probability of leakage will be less than e.g. 5 %.

How should we define CO2 leakage?

The Monte Carlo approach was used in this study, whereby thousands of fast, simple leakage simulations were performed. In each simulation, leakage through microannulus was modelled. The aperture of microannulus was a random parameter varying along the well.

In order to call a well “leaking” or “non-leaking” in each of these simulations, as in real life, a threshold for the flow rate needs to be chosen. Wells that produce flow rate above the threshold are “leaking”, others are not. One of the outcomes in Monte Carlo simulations was that the recommendation on the safe cement sheath length strongly depends on how we chose this threshold, i.e. how we define CO2 leakage.

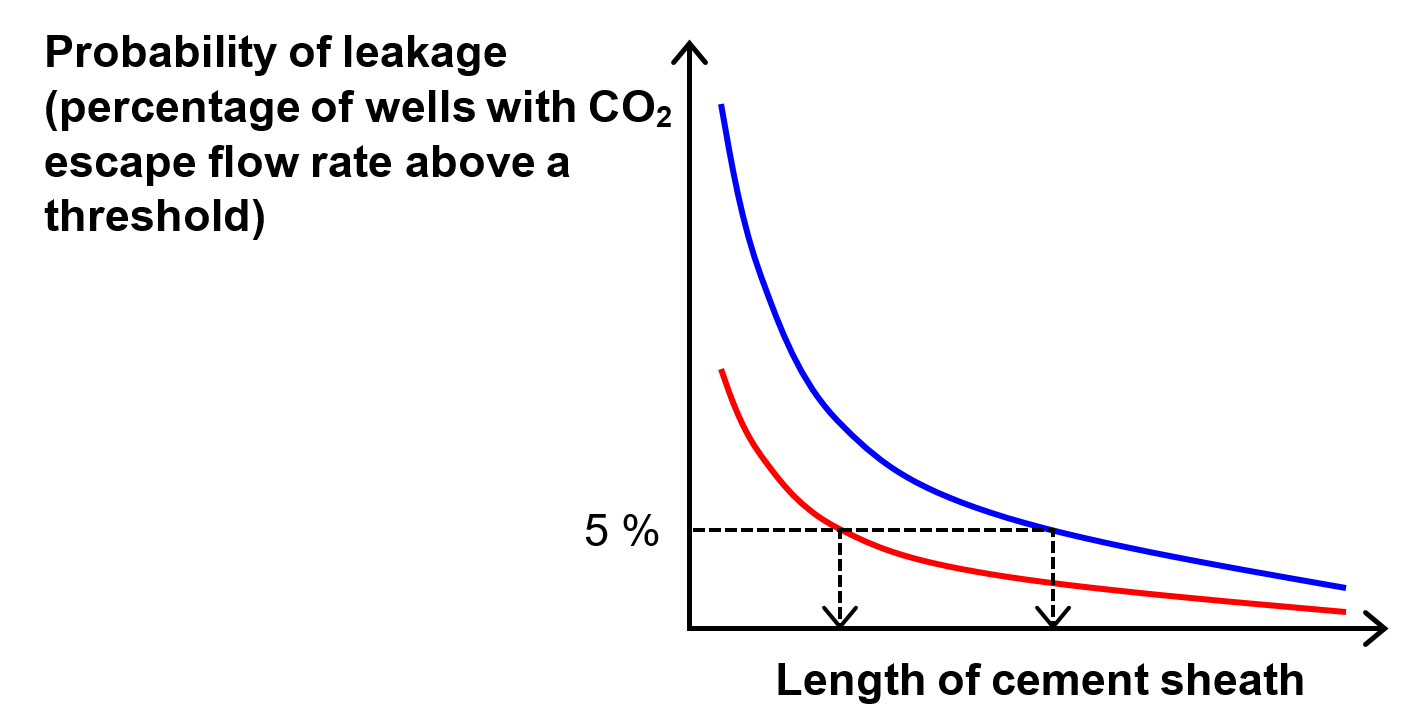

Take a look at figure below. It shows two curves, each representing hundreds of thousands of Monte Carlo simulations. The only difference between the two curves is how we define leakage: The threshold is set higher for the red curve, i.e. higher escape flow rates for CO2 are allowed here without recognising the well as leaking.

How we define leakage substantially affects the recommended cement sheath length.

Monte Carlo simulation is a powerful tool that accounts for uncertainty in complex systems like CO2 storage sites. However, there are some inherent uncertainties in the method itself. In particular, properties of the microannulus aperture distribution are unknown. A sensitivity analysis has shown that the properties of the distribution may affect the simulation results substantially. In particular, when the variation in the microannulus aperture increases, a shorter cement length is needed to ensure well integrity. The reason is that there is higher probability, in this case, that the microannulus will be completely closed at some location along the well, thus preventing leakage altogether.

Mont Terri Experiment: Studying Caprock and Fault Sealing Integrity

Can we assess a minimum length for safe well cementing?

Stochastic approach sheds new light on leakage prediction and risk analysis in CCS. The risk of leakage is difficult to predict and the minimum allowed cementing length is almost impossible to assign. A unique minimum allowed length of cement sheath does not exist since a slight variation in model parameters may lead to a different recommendation for such length. That said, increasing the cement sheath length does reduce the probability of leakage in a given well. However, it is impossible to say with certainty at what cementing length the well will always be non-leaking.

On top of that, stochastic modelling puts more advanced and accurate numerical models of well leakage into new perspective. What could be the real value of advanced leakage models? The Monte Carlo study suggests that it is naïve to expect that the value of more accurate and advanced numerical models is an exact prediction of leakage. Given the uncertainties involved in the real-life CCS, such an accurate prediction will hardly ever be possible. The value of advanced numerical models of leakage lies elsewhere.

In particular, these models enable to quantify the effect of different parameters on the leakage risk and to isolate the most crucial factors. Such parametric studies are one of the ways numerical modelling has been used in geosciences for the past decades.

Questions for further research

The stochastic approach also poses some new questions

- Can we come up with an objective, science-based definition of leakage? Should such definition be based on the resolution of monitoring techniques currently available? Will this definition change in the future?

- How could best well-construction practices be established, e.g. the minimum allowed cementing length?

- How can we gather more input data for numerical models, given that there is no direct access to the downhole?

Further work should address these issues.

Learn more about CCS

Join our newsletter to stay updated with all the latest research results and news from NCCS: The Norwegian CCS Research Centre.

Acknowledgement

The research was performed within the project “Studying moving fluid interfaces during cementing of CCS wells” (268510/E20) funded by the Research Council of Norway through the CLIMIT program.

Pingback: SINTEF builds a new Hele-Shaw cell to understand two-phase flow in natural fractures - #SINTEFblog