The BATMACHINE project, where SINTEF plays a key role, addresses this issue by introducing the equipment Wrapper: a lightweight digital interface that gives every machine a standardised “passport”, enabling easy integration into the project’s data ecosystem.

Functions of the wrapper

The wrapper acts as a harvester, translator, and enhancer for machine data. It performs three essential functions:

Data ingestion

The system is designed to capture data from any source, whether it’s a live production line or an offline lab environment. Online machines stream real-time OPC UA data directly into a time-series database, ensuring immediate availability for analysis. Meanwhile, offline machines, such as lab testers, are given structured schemas so their output looks similar to any other sensor streams. This unified approach ensures that all data—live or batch—is collected in a consistent and usable format.

Data discovery

To make data more accessible, the wrapper maps technical tags like “T_SetPnt_03” to clear, human-readable terms using a shared battery manufacturing ontology. This allows engineers to search using intuitive language, such as “Dryer bottom temperature,” and retrieve relevant data from different machines and production lines.

Context-rich data

Beyond raw values, the system adds meaningful context by embedding metadata such as machine function, subcomponents, and physical dimensions (e.g., dryer length). This contextual information enriches the data, making it easier to interpret and enabling more accurate analysis and better decision-making.

Building a wrapper

Creating a wrapper is a collaborative process that brings together expertise from multiple domains. Machine experts begin by identifying the key operational parameters that define how each piece of equipment functions.

Next, semantic expert maps these parameters to existing ontologies or extend them to include new, battery-specific concepts. The result is a compact set of JSON/CSV files, deployed in lightweight containers with visual dashboards layered on top for easy access to information for process tuning and optimisation

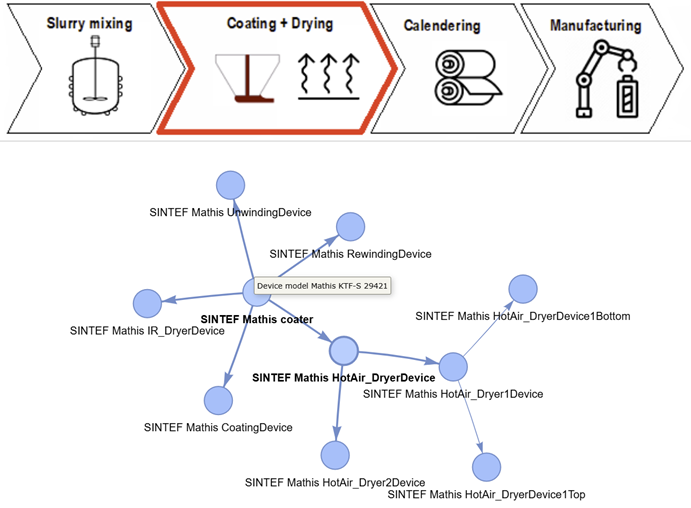

Pilot run: Wrapping the Mathis slot die coater

We tested the wrapper on a roll-to-roll coater machine that lays down 200mm electrode films. From hundreds of available signals, we selected key set points like web speed and global readings like dryer temperature.

These were categorised into “control” and “state” groups and mapped to EMMO-compliant terms. The pilot also revealed gaps in the domain ontology, which we addressed to support future scalability.

Why this matters

By giving machines a shared digital language, wrappers make data traceable, reusable, and ready for automation.

This allows for:

- Automated recipe tuning

- Faster ramp-up of greener European battery production lines

- Seamless integration of lab insights into factory control

Standardising machine semantics is key to integrating equipment from various manufacturers. The equipment wrapper makes this not only possible—but practical.

Comments

No comments yet. Be the first to comment!