Well construction in oil & gas and geothermal industries becomes increasingly complex and costly as the target depths increase. New ways to reduce costs and improve safety are therefore actively researched. Electrophoresis , a physicochemical effect known from the early 1800s, may help in reducing costs in drilling and well construction. In particular, it may facilitate cleaning of the equipment. It also may reduce energy consumption when drilling fluid and cement are pumped into the well.

Electrophoresis 101

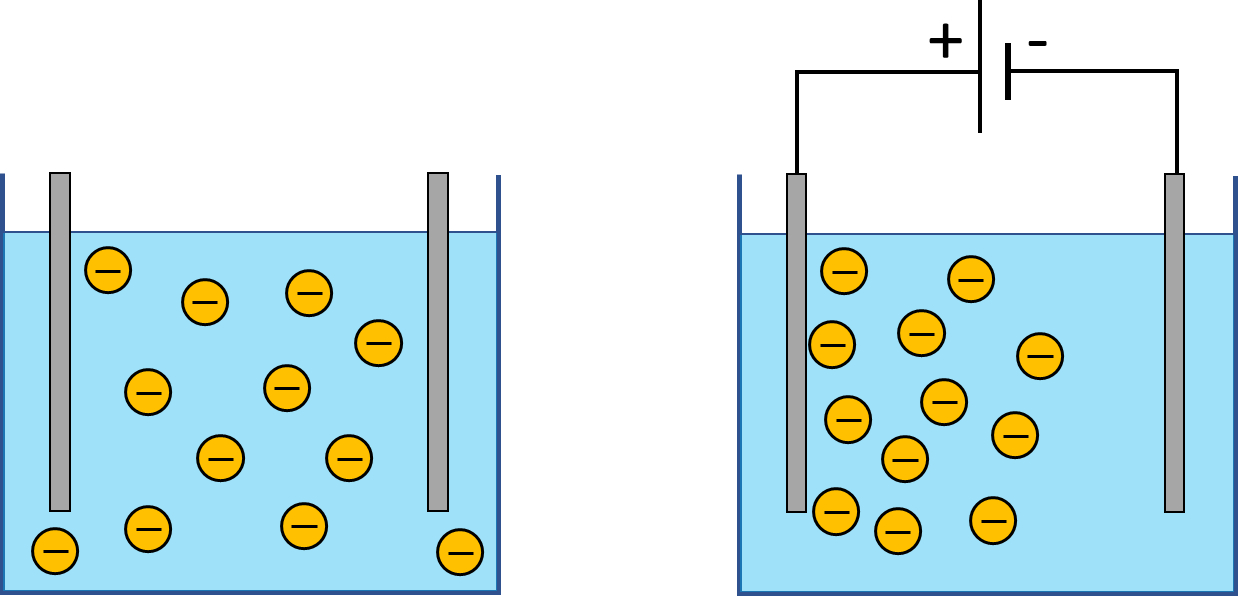

Many fluids used in drilling and well construction are suspensions of small particles in a liquid. Often these particles carry electric charge. For instance, clay particles present in drilling fluids usually carry negative charge. This charge appears e.g. when ions in clay minerals are substituted with ions present in the carrier fluid. Similarly, cement particles often carry charge as well.

If an electric field is applied to such a suspension, charged particles tend to move towards the electrode of opposite polarity. This effect is known as electrophoresis. Perhaps the best-known application of electrophoresis is in forensic science where it is used to separate DNA molecules.

Electrophoresis and wells

Our recent experiments suggest that electrophoresis could find new applications on a larger scale, namely when fluids are pumped into wells during drilling and well cementing. Pumps, mixers, and other equipment used to handle drilling mud and well cement need to be cleaned up in the meantime. Applying negative potential to metal surfaces might facilitate cleaning, reduce the amount of water and improve the cleaning efficiency, thus saving time and money.

Laboratory tests look promising for the ElectricCleaning technology: Steel electrodes were immersed in cement slurry; after application of 18 V during 18 minutes, a clump of cement accumulated at the positive electrode, while the negative electrode was almost clean (see photo below). A reference test with no voltage showed intermediated results.

Electrophoresis might also be found useful for reducing frictional losses and wear while pumping fluids into the well. For instance, during drilling, a particle-laden fluid is normally pumped down the drill pipe, and it returns to the Earth’s surface in the annular space between the pipe and the wellbore wall or casing.

Mud pumps need to overcome frictional pressure losses that the fluid experiences on its way down and up. If electrophoresis can indeed reduce the frictional pressure losses, by repelling particles from the pipe wall, it may be an easy way to lower the energy consumption and emissions on the rig.

Ongoing research in SINTEF Industry

Electrophoresis is a complex process. Applying this process requires multidisciplinary expertise in well technology, drilling, fluid mechanics, and electrochemistry.

Several fundamental questions must be answered before this technology can be evaluated for the field:

- How does the fluid composition affect the cleaning efficiency and friction reduction? Can additives used in cement and drilling fluid be finetuned to control the effect?

- Is AC or DC more effective?

- What are the optimal field parameters, such as voltage and spatial shape?

- Should gas development be avoided? Could gas development be exploited in order to enhance the cleaning effect?

Ongoing research at SINTEF Industry should provide answers to these questions and quantify the observed effects.

Comments

No comments yet. Be the first to comment!