CO-author: Pål Ystgaard in SINTEF Manufacturing

The development process of a product consists of different phases, including concept generation, concept and product development, detail engineering and testing. We often talk about rapid product development but seem to forget that setting up a production with the desired cost efficiency and yield is a time-consuming task.

In manufacturing, assembly is one of the more complex tasks and there is often a need for cheap labor. If your assembly is based on manual labor, you can rapidly adapt your production to new products. In high cost countries, like Norway, to heavily rely on manual labor is not preferable and labor cost is the key driver to out-source production. On the other hand, there are plenty of reasons that you would like to keep or re-shore your production; intellectual property, quality, control of value chain, short lead times, time-to-market, etc.

Flexible assembly

Traditionally automation is cost efficient on high volume products, but cost reduction on equipment. Technological advances in the field of robotics have allowed for the automation of medium and small volume production series. With flexible assembly cells, several products can be assembled with the same hardware and the investment cost can be divided over more products. However, we still see that the engineering cost to implement new parts in a flexible system is a large part of the total cost. Mechanical designers and product development engineers seldom understand how an automated assembly process works making use of feeders, machine vision, grippers and robots. This can render in a situation where a finished product, ready for production, becomes very complicated to assemble using robots and automated assembly technology.

In the FREM project, Barco and SINTEF Manufacturing are joining their forces in order to narrow the gap between design, product development and production. The main goal is to integrate the design process with production and to a much larger extent adapt the product design to existing production process, rather than adapt the production process to the product.

Design for automated assembly

Design for manufacturing and design for assembly are well known techniques that have been around for a long time. The concept of design for automated assembly (DFAA or DFA2) was introduced in 2001. Specific challenges with automated assembly are highlighted in this approach.

Examples of these challenges are assembly direction, tolerances and feeding of parts to the assembly. The DFAA design rules are aimed at automatic assembly, but a product designed for automatic assembly will also be easy to assemble manually. In fact, in several of the cases that were evaluated during the FREM project, a redesign based on DFAA-techniques led to a so large reduction of manual work that automation of the process was not feasible.

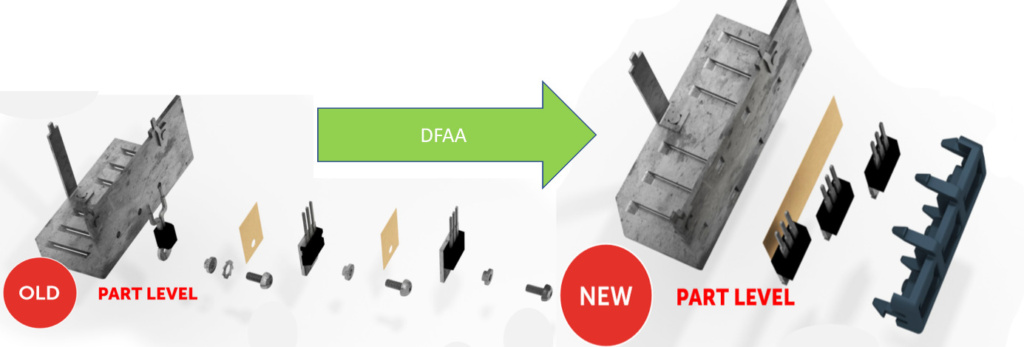

Bellow you can see an example from Barco where DFAA was used on a heat sink assembly. The number of parts has been reduced from 13 to 6 and the total cost of subassembly was reduced by almost 50%. Reduction of parts and simplification of the assembly process, like seen bellow, will reduce the need for feeding systems to the manufacturing cell and need for special tooling, fixtures and jigs and therefore reduce the cost of the assembly cell. Both equipment and engineering cost.

Some extensions and modifications to the established DFAA-technique were made in the FREM project. One example is the use of machine vision for the detection and feeding of parts. Use of machine vision for the feeding of parts to cell is a key element to allow for flexible assembly. Input parts to an assembly cell can be semi-structured or unstructured (in a bin) and the parts can be located with a machine vision system. There are some considerations that can be done in design that would improve the ability for a machine vison system to locate parts. For example, a part with a large shiny surface can be very difficult to detect for a machine vision system but by adding a well-chosen design feature the part can be accurately located.

Automate automation

A tool has been developed in the FREM-project for use in the design process. The designer can evaluate the product based on DFAA-techniques and as early as possible decide how the specific part should be fed and manipulated based on the equipment already present in the production facility. Parts are analyzed and rated on how the equipment used in automated assemblies will handle the parts and how the design is done to allow for automated assembly.

We are now in the final stage of the project and aiming to take this to the next level with the help of a demonstrator. Here the assembly sequence and skills needed by the assembly system will be defined in a 3D design tool. By defining the assembly tasks, assembly direction and what tool and skill to use in the assembly process, the system will generate robot paths and logic to perform the assembly. The assembly can be simulated in a digital twin of the assembly cell and verified “on-the-fly”. When the design is complete, the assembly sequence can be implanted in the physical cell. The goal is to minimize the engineering tasks needed to set up an automated assembly process and thereby make automation cost-efficient for products with small production volumes.

From No-Go to Go-Go!

A design review of your product with focus on assembly is the first step to automate your production and this can dramatically change the preconditions for automation.

SINTEF has supported Norwegian companies in several projects to understand how to design and allow for a product to be assembled using today’s automated assembly technology. We analyse the components in a typical assembly/product and rate the parts using methods to understand how the parts will function in an automated assembly set up. As an independent technology solution provider, we can give guidance to support companies for a more cost efficient and productive manufacturing and assembly system in Norway rather than look for production capacity abroad.

SINTEF is the first step towards automation of both production and assembly. We will support the initial proof of concept and give input on the decision to, or not to automate. The next step will be to get an automation integrator to take responsibility for hardware and finalization of an automated assembly line.

Comments

No comments yet. Be the first to comment!