You’re probably wondering what the concept of “hygge” has to do with the acronym WoodCFD, and from time to time so do I. The Scandinavian concept of “hygge” has come to mean that warm cosy feeling you get sitting in front of a wood stove or built-in fireplace. It is literally feeling the warmth from the flames dancing behind the glass, and hearing the tiny explosions made by the logs giving off sparks.

No other form of combustion technology can provide the “hygge” experience while at the same time acting as the main source of heating in our homes and cabins.

But the world is changing, and change means more restrictions on this traditional method of heating – introduced both in response to pressure to reduce emissions, and to changes in the regulations governing energy efficiency in new-build homes. Of course, such requirements are very sensible, but they also mean that wood stove manufacturers have to think innovatively in order to keep both consumers and the public authorities happy.

Old emissions limits on the way out

Consumers, who still crave “hygge”, needless heat to warm up their modern homes and this puts demands on the heat output specifications for new wood stoves. You can still open a window if it gets too hot, but this is hardly the smartest thing to do if your new home is designed with balanced ventilation. This can make the economics of using your stove much less attractive.

The public authorities want lower levels of polluting emissions and new emissions limits are on the way. Older and relatively high emissions limits are now on the way out. They have been fixed for too long now, and no longer reflect advances in heating technology.

Wood stove manufacturers are well aware of this situation and are battling for their existence as alternative heating technologies advance into the market. In the first instance, these alternative technologies have a major advantage – either because they are run on electricity or are electrically regulated.

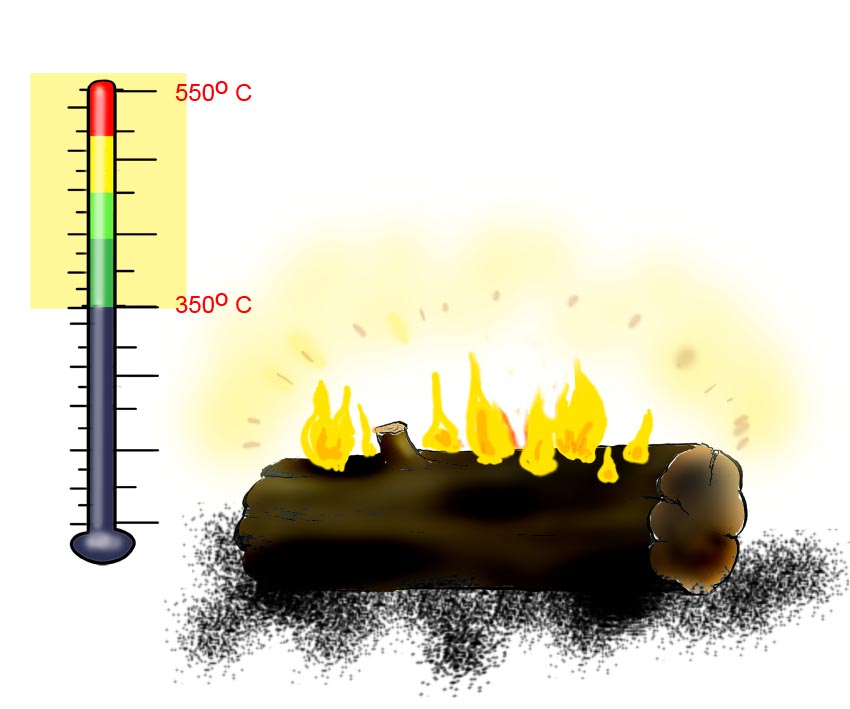

Wood stoves, which involve a single batch of logs lit manually one at a time, are thus at an immediate disadvantage compared with these alternative heating technologies. This is because burning logs in a wood stove involves a so-called transient combustion process, in which the material being burned is constantly changing its nature throughout its combustion. This means that heat generation is also continuously changing, which in turn also means that the heat component conducted through the stove wall and finally out into the room is also constantly changing.

What will tomorrow’s wood stoves look like?

The potential for levelling out the output of heat into a room, as well as the possibilities of extending the combustion cycle or increasing the heat storage capacity of stoves are thus very interesting topics for research. Of course, stoves can be made smaller, but this places limits on their practicality, aesthetics and the “hygge” factor. Whatever you do, emissions must not increase. Ideally, they should be reduced.

So, we have two options for the development of new wood stoves. Option 1 is to run to the labs operated by wood stove manufacturers or research centres, basing our work entirely on experiments and empirical data. This is the traditional and by far the most popular method, carried out with little or no support from computer-based computational tools. This approach can quickly become very demanding in terms of time and costs, and the results may be far from optimal.

Log combustion in a wood stove can be regarded as the most complex combustion process in nature.

Option 2, which is no longer the stuff of science fiction, involves the use of simulation tools based on physical models that describe in detail what happens during the combustion process. Such tools offer us previously undreamt-of opportunities to study the influence of the fuel, stove design and operation on the combustion process, and thus also the emissions and heat output generated during the process. Theoretically, it becomes a simple matter of changing the key parameters as a means of optimising wood stove performance.

Unfortunately, there is still a touch of science fiction involved because I can say with my hand on my heart that wood log combustion in a wood stove can be regarded as the most complex combustion process found in nature. It requires a detailed understanding of what is happening during the combustion process, and an ability to construct models that describe the process in sufficient detail. Sufficient is the key word here, because computing power places constraints on detail when the simulations become too complex.

WoodCFD – clean-burning and efficient wood stoves

Back to the acronym WoodCFD. It belongs to a skills development project funded by the Research Council of Norway and four wood stove manufacturers with the long title “Clean and efficient wood stoves through improved batch combustion models and CFD modelling approaches”. CFD stands for Computational Fluid Dynamics.

- If you want to find out more about WoodCFD, you can dip into the handbook issued by the project.(In Norwegian)

This probably sounds a little, or perhaps very, dull and tedious to many people. But it has in fact been a very exciting 4-year project (now coming to an end) in which SINTEF Energy Research, together with NTNU, has been studying very closely the different factors that influence combustion in, and heat output from, wood stoves, as well as the impact of heat output on the levels of heat comfort experienced in different types of buildings and in a variety of climates.

Our work has resulted in models and modelling approaches that have made great advances in making it possible to base future wood stove technology development on Option 2 simulations.

Simulation tools for wood log combustion resulting from the WoodCFD project

Specifically, the project has addressed both the development of a detailed wood log combustion model and the correct selection and use of a series of other models used to encompass all the component models that have to be included in the simulation tool box.

Testing of the simulation tool has involved simulations of the entire combustion process taking place in a real wood stove, including all essential design specifications such as heat storage in the materials making up the stove. The effects of the resulting heat output profiles on levels of heat comfort in rooms and buildings have been studied in detail.

In order to perform adequately detailed simulations throughout an entire season of stove use, models have been developed for inclusion in building simulation tools, which also take sufficient account of heat circulation in individual rooms. A Ph.D, a post doc., and a number of other students have made contributions to the project, together with their tutors and research scientists at NTNU and SINTEF.

Future research challenges

The most important thing we lack now in our attempt to obtain a detailed and comprehensive wood stove simulation tool is a fully integrated tool in which input is represented by start values only and all other values are computed during the course of the combustion process. This requires direct coupling between the decomposition of a wood log and its surroundings. There is also a need to optimise the simulation tool in order to make it as efficient as possible. This is demanding work and fully justifies a new research project.

This is why the WoodCFD consortium sees an essential need for a follow-up project that will provide a comprehensive wood stove simulation tool that can make an effective contribution to the development of future wood stoves. This can be supplemented with precisely selected laboratory experiments and guidelines based on building integration simulations and input from consumer surveys in order to ensure the optimal integration of wood stoves in tomorrow’s energy efficient buildings.

If you have any questions, please contact Project Manager Øyvind Skreiberg.

And finally – two tips on how to use your stove

You have by now probably started to use your stove and of course you know everything about how it works. Or perhaps you only think you do? If you feel that you belong to the second group, why not take a look at the user manual that came with your stove. Here you will find some tips about getting the best out of your stove. If you’ve lost the instructions, you can always find some excellent tips online. For example, why not check out this Gemini article.

So, enjoy your wood stove season, but don’t burn your Christmas tree in the wood stove when Christmas is over!

Comments

No comments yet. Be the first to comment!