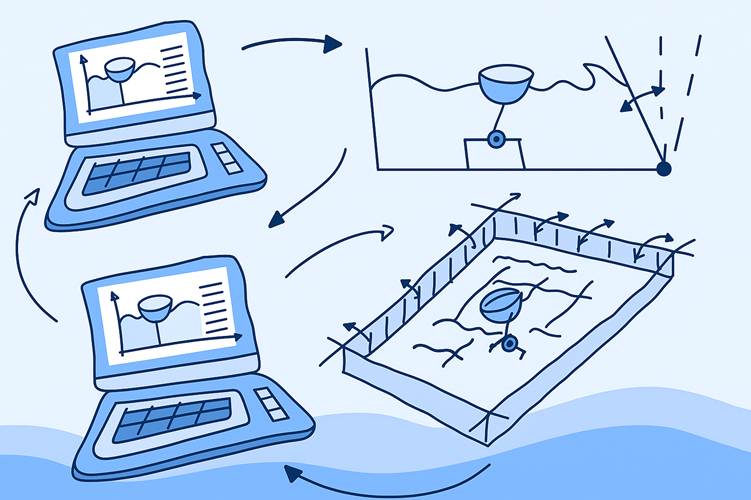

So how do you go from a notebook sketch to generating real power from the ocean? Where do you begin? And how can SINTEF support you along the way?

The 6 stages of technology development

The IEA-OES “Evaluation and Guidance Framework” shows us a structured path for developing ocean energy technologies — and it’s especially relevant for wave energy. It divides development into 6 stages, from spark-of-an-idea to a working power array.

| Stage | Description | TRL (Technology Readiness Level) |

| 0 | Concept Creation | TRL 1 |

| 1 | Concept Development | TRL 2–3 |

| 2 | Design Optimisation | TRL 4 |

| 3 | Scaled Demonstration | TRL 5–6 |

| 4 | Commercial-scale Single Device | TRL 7–8 |

| 5 | Commercial-scale Array | TRL 9 |

Each stage has specific activities and evaluation criteria within 10 Evaluation Areas:

Power Capture, Power Conversion, Controllability, Reliability, Survivability, Maintainability, Installability, Manufacturability, Affordability, Environmental Acceptability.

Progress is NEVER linear — you’ll test, revise, and loop back more than once!

What happens at each stage?

Let’s walk through them in the context of a wave energy project…

Stage 0: Concept creation

“Can my idea work at all?”

This is where you define your idea for a Wave Energy Converter (WEC): what it does, what problem it solves, and how it interacts with ocean waves. Use basic physics to estimate its wave energy capture potential and compare it to existing wave energy technologies.

Your concept must be grounded in sound physical principles: basic understanding of water wave physics is obviously essential. Creativity is key here, but it must be backed by logic and simple, reliable, calculations. A compelling wave energy concept is one that translates into the language of engineering: clear, physics-based reasoning – not just intuition!

A small, functional, Wave Energy Converter (WEC) prototype tested in a small tank (bathtub?) or accessible body of water is more useful at this stage than expensive wave tank testing, which is not designed for early idea visualization.

Thousands of patents exist for wave energy devices that merely absorb energy. What sets your WEC apart must be its novelty and potential to “do better”.

Stage 1: Concept development

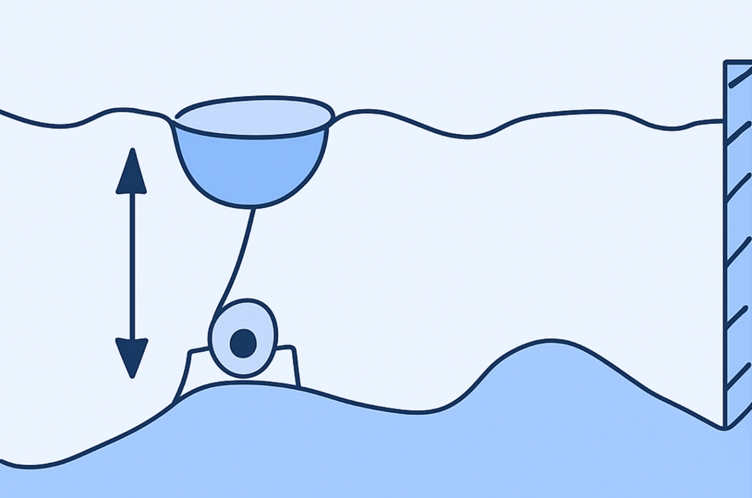

“Can I develop a reliable numerical model, supported by targeted experiments?”

At this stage, you develop your first numerical model to simulate the device’s performance under various sea conditions. You begin wave tank testing of small-scale physical models to validate and calibrate your simulations.

You also start exploring key engineering aspects such as mooring, control strategies, and incorporate basic models of the Power-Take-Off (PTO) system. Preliminary estimates are made for energy absorption, system forces, and motion responses.

By the end of Stage 1, you should have specific, simulation-based, insights into your Wave Energy device’s performance. These are far more refined than earlier back-of-the-envelope calculations and helps bridge the gap between theoretical design and real-world behaviour.

Stage 2: Design optimisation

“Can I design this for real-world conditions, with manufacturing and control in mind?”

At this stage, (advanced) engineering takes the lead. The fundamental principles have been established, and the focus shifts to refining your design for real-world application. Your numerical models are improved, and more realistic scale prototypes are built to run more complex, integrated, experiments.

The R&D effort now centres on performance optimisation of the Wave Energy Converter. Key systems, such as mooring, structural layout, and material selection, are designed and fine-tuned. Simpler placeholder models are replaced with higher-fidelity simulations. You may begin working closely with PTO (Power-Take-Off) developers, while control systems, especially for the PTO, are fully integrated and tested.

These systems are developed in parallel, making this phase highly iterative and time intensive. Testing becomes more demanding, with extensive wave tank experiments and dry testing of components like the PTO.

By the end of Stage 2, the WEC design must be fully engineered for real-world use, having passed qualification tests that demonstrate it is ready for scaled ocean trials. Testing in the lab under extreme wave, current, and wind conditions is essential to validate both performance and structural integrity.

Stage 3: Scaled demonstration

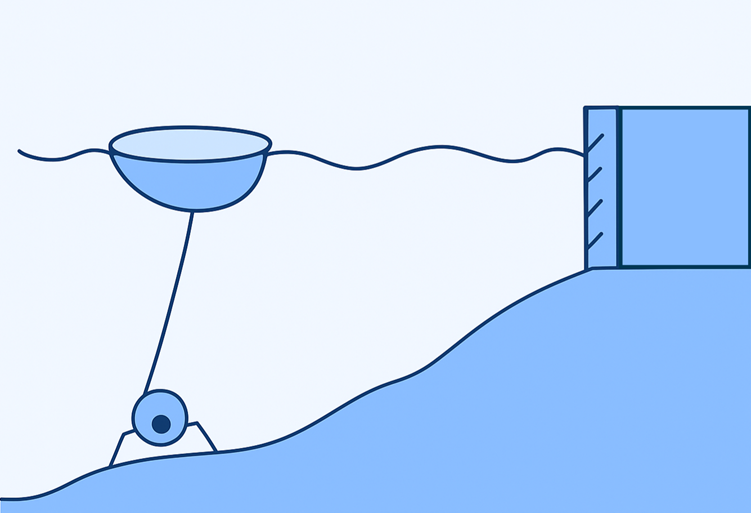

“Does it work when exposed to real waves, weather, and currents?”

Now you’re in the sea. Your tech is still scaled down, but you test it in real sea states. Data collected here is vital for validating models and understanding survivability and reliability.

Stage 3 marks the shift from controlled laboratory development to the unpredictable conditions of the open ocean. At this point, the design has been validated through simulations and tank tests, and a partially scaled prototype –typical scales are between 1:4 and 1:2 scale – is deployed at sea. The primary aim is to demonstrate the Wave Energy system’s survivability, stability, and basic performance in real wave, wind, and current conditions. While not yet focused on commercial energy production, this phase is essential to verify that the system behaves as expected under real-world environmental loads.

The demonstration allows for detailed observation of system response, control strategies, and energy conversion under dynamic marine conditions. It’s also the first opportunity to evaluate practical aspects such as installation, maintenance procedures, biofouling, corrosion, and general durability. Critical data is collected to assess performance, efficiency, and identify potential failure modes, guiding further design refinement and reducing uncertainty for future upscaling.

In many cases, the WEC prototype may be connected to a test grid or load bank to assess power quality and consistency. Regulatory compliance, environmental assessments, and maritime permits become an important part of this phase.

By the end of Stage 3, the technology should have proven itself in a marine environment, providing strong evidence of its potential and greatly increasing its credibility with investors, partners, and regulatory bodies.

Stage 4: Full-scale single device

“Can I run a real machine continuously and safely?”

At this stage, you’re no longer asking “Can it work?” but rather “Can it survive? Can it deliver power continuously?” Real-world wave climates, including in Norwegian waters, are demanding!

This is the moment when a wave energy concept first proves itself in the real ocean — at full size! After years of simulation, tank testing, and scaled demonstrations, Stage 4 is where everything comes together: the mechanical design, the control systems, the mooring strategy, the power take-off unit. It’s the first true commercial-scale deployment, and it often takes place at a designated test site with grid access and monitoring infrastructure.

The focus now is on collecting high-quality WEC operational data over time. You’re assessing energy yield, uptime, environmental interactions, and maintenance cycles. You also begin testing support operations like vessel access, remote control, and fault diagnostics.

Many technologies never reach this point, and for good reason: Stage 4 is expensive, risky, and complex! But it’s also where credibility is earned. Investors, regulators, and industry partners often look at successful full-scale testing as the clearest sign that a product is ready for serious consideration. A successful Stage 4 deployment means you’re close to a bankable product.

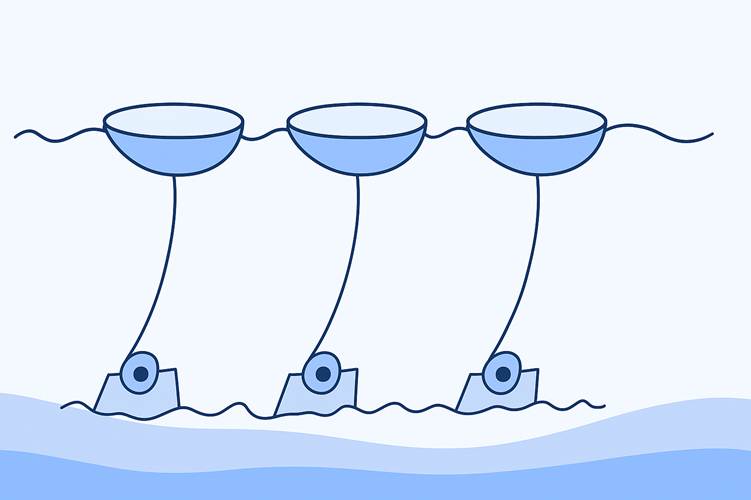

Stage 5: Commercial array

“Can I make this competitive with other renewable energy sources?”

Now it’s about scaling up: multiple devices, shared infrastructure, and energy delivery at scale. You’re solving system-wide issues like grid connection, cost optimization, and long-term maintenance.

Stage 5 marks the transition from innovation to infrastructure — the point where wave energy technologies aim to operate as part of a real-world power system. Here, multiple WEC devices are deployed as an array, sharing infrastructure and delivering electricity to the grid at meaningful scale. It’s not just about proving technology anymore — it’s about demonstrating coordinated system performance, operational stability, and long-term viability.

Reaching this stage demands much more than simply scaling up. Hydrodynamic interactions between Wave Energy devices, shared cable systems, and array-level maintenance strategies introduce new engineering and logistical challenges. It’s also where cost assumptions meet reality: construction, operation, and support must all be balanced to show a credible path toward competitive energy production. While full-scale arrays are still emerging, each step toward them strengthens the case for wave energy’s role in a future energy mix.

This stage brings together more than just hardware. Planning, permitting, insurance, supply chains, and environmental compliance all become central. The focus expands from “can this work” to “can this be built, repeated, and financed?” Success here lays the foundation not just for one project, but for a deployable Wave Energy technology class.

A non-linear journey

The process isn’t always clean. WEC devices often go back and forth between stages. Why? Because testing reveals new insights, systems evolve, and ocean conditions throw surprises.

Setbacks and doubts are normal and expected. Iteration is a sign of quality, not failure!

However, the fundamental aspect of this approach is that you should not progress to the next stage without having completed successfully the stage you are in, including all relevant evaluation areas.

For students and early-stage innovators: How can you start?

- Study the basic physics of ocean waves and how energy can be extracted from their motion.

- Build simple scale WEC models to test your ideas. Even small experiments at home can teach you a lot.

- Learn to use basic tools for design and analysis, such as spreadsheet calculations, sketching software, and simple simulation programs.

- Explore the vast amount of knowledge available online concerning Wave Energy. From technical reports and public data to tutorials and past project results. A Prime source is the THETHYS Marine Energy Knowledge Base, while the (still) relevant 2008 practical review Wave Energy, and the open access Handbook of Ocean Wave Energy are also worth mentioning. Read widely and often!

- Start small and stay curious! Progress comes from consistent learning, listening to feedback, and building on the work of others.

How SINTEF can help you?

Whether you’re refining your Wave Energy concept, testing a prototype, or preparing for deployment, SINTEF is here to help you take the next step with confidence.

At SINTEF, we support wave energy developers through every stage — from early concept to commercial deployment — with deep technical expertise and world-class facilities:

- Feasibility studies, concept validation, and design guidance

- Wave resource assessment and environmental modelling

- Numerical modelling, including multibody and hydro-elastic analysis

- Tank testing, rig testing, and Hardware-in-the-Loop experimentation

- Wave-to-grid and control system modelling

- Lifecycle analysis and sustainability, and grid integration studies

- Independent evaluation and stage gate reviews

Visit our Wave Energy Research Area to learn more!

Comments

No comments yet. Be the first to comment!