2050 is now less than 27 years away – when the world has set a goal for becoming climate neutral. Capturing and storing gigatons of CO2 annually is a crucial part of achieving this goal – but to do that, we need more open innovation. We need to collaborate and share knowledge, even if we are competitors. We might have the money, but we do not have the time to fail.

We need to scale up our efforts on CCS

Scaling up CO2 capture, transport and storage (CCS) is crucial for avoiding the climate and biodiversity crisis. Investments in CCS are picking up, but a lot more is required – particularly in relation to CCS research. We are entering an energy revolution, and if CCS is to meet its expectations as a required climate mitigation tool, the CO2 storage capacity needs to reach the gigatonne scale.

The vision of the Norwegian CCS Research Centre, NCCS, is to fast-track CCS deployment through industry driven, science-based innovation. NCCS is the largest CCS research centre in the world, and we are extremely proud of our international partnership. We have end users, vendors, universities, and research institutes in the centre. NCCS covers the full CCS chain, and associated issues like business models, the cost of CCS, and the legal and regulatory framework are crosscutting topics in the centre.

Longship’s success proves we need more research

A full-scale CCS project like Longship has been developed on the knowledge base generated over decades of open innovation in Norway. It is due to set sail next year (2024). Does this mean that we do not need more research? NO.

Future, full-scale projects will continue to pursue more effective CCS value chains. Engineers will have important questions for these types of projects, such as “what is the condition of the CO2 mixture at the various locations in the system?” and “Which phases do we have in the system?”. In order to answer these questions, we need models, and models need data for their development and verification.

Sigurd Løvseth and the CO2Mix facility: creating value for CCS deployment for decades to come

One person who understood this need all too well was my colleague, Sigurd Løvseth, who sadly passed away unexpectedly from cancer last year. The first facility Sigurd planned was the vapour-liquid equilibrium (VLE) facility: CO2Mix. Planning for the facility started back in 2009, but it took seven years, and a lot of challenges on the way, before the results were published.

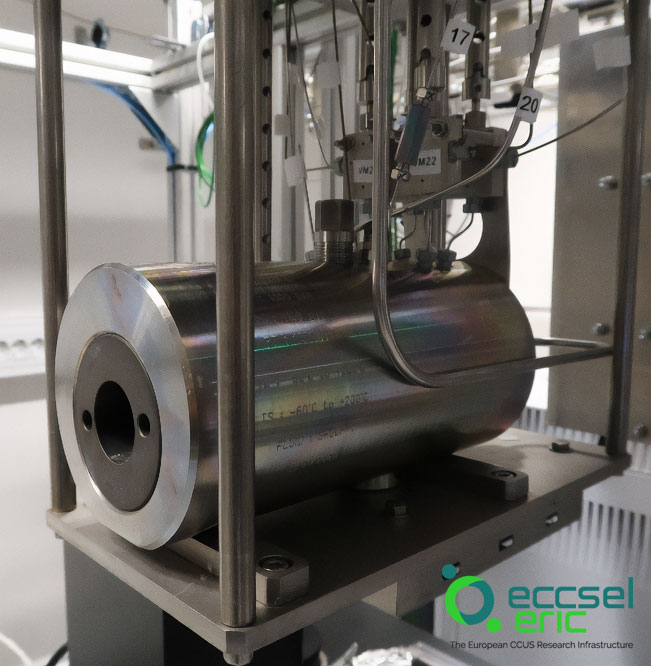

I believe we can learn something from Sigurd’s work with this facility. His strategic approach, combined with world-class research and a bit of stubbornness has produced direct value for CCS deployment. Every data point from this facility is published and used in models and simulations tools. The picture below shows a new phase equilibrium cell. It can operate up to 1000 bars of pressure and handle complex fluids, including salts. It will create value for CCS deployment for decades to come.

Sigurd left behind a legacy of CCS research facilities, know-how, colleagues, and publications, with the potential to impact the CCS deployment for decades. Thanks to Sigurd and his co-workers.

We need closer collaboration between research and industry

Since the pace of CCS implementation is of the utmost importance, industrial actors must make use of existing CCS knowledge to secure the necessary investments. One way to do this is to join gigaCCS, the new Centre for Environment-friendly Energy Research that will take over NCCS’ mission when the Centre comes to an end next year.

We need to bring research and deployment closer together. We need more research and closer collaboration with industry. We need to collaborate and share experiences. We need to secure knowledge that can be used for deployment as well as research new questions that arise from deployment activities.

The future of our children is at stake. We do not have time for failures.

This blog post is based on the keynote speech of the same name given by Mona Mølnvik at the 12th Trondheim CCS Conference (TCCS).

Comments

No comments yet. Be the first to comment!