According to our last study, the definitive answer to this question is no; based on our results, we concluded that, under steady-state conditions, wind energy cannot be used solely to power the processing system, and another power source must be employed to compensate for intermittent wind power generation. However, another question arises: Is it worth utilizing wind energy for oil and gas platforms? Certainly, based on our findings, the integration of wind energy could reduce CO2 emissions significantly. We studied this issue in our last journal article, which you can find summarized here.

- Find out more about LowEmission research centre.

Wind Power as an Alternative to Gas Turbines

Gas turbines that use natural gas or diesel to power compressors and pumps account for approximately 85% of CO2 emissions in offshore oil and gas facilities. As a result, the oil and gas industry seek a suitable alternative to gas turbines in order to improve the environmental friendliness. and sustainability of offshore platforms. However, gas turbines have the advantage to provide significant power (in the order of tenths of MW), in a stable manner with low footprint. It is therefore important that the alternative provides significant amounts of power in a stable manner. Our research examined how wind power can be used as an alternative since it has been exploited on a large scale in recent years and proved as competent source of energy.

Utilizing Dynamic Process Simulation with K-Spice SimExplorer

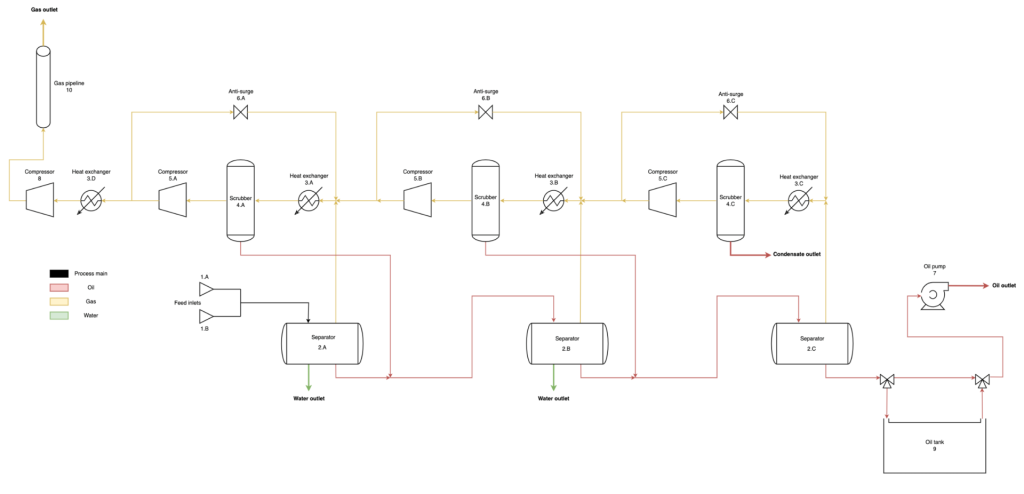

Nevertheless, using wind power is challenging because offshore oil and gas installations require a fairly constant and reliable source of power, while wind power typically exhibits significant fluctuations. Therefore, the possibility of supplying the necessary power for the system through wind energy was investigated. First, a dynamic process simulation tool, K-Spice SimExplorer by Kongsberg, has been used to model the processing system (shown in Figure 1) and to calculate the overall power consumption trend for our case study. We considered three options. The first is producing and consuming wind power simultaneously with small backups of gas turbines.

Figure 1. Process flow diagram of the topside processing system.

In the second option, wind power can be produced, stored in the subsurface for example, by generating hydrogen or ammonia during periods of high wind generation, and then consumed during periods of low wind generation.

In the third option, gas turbines can be integrated with these two green energy sources to provide power when there are power deficits. For the last two options, a numerical optimization was formulated to determine the minimum size required for the energy storage system and the highest possible constant power that can be delivered. In the optimization, for the second option, it was assumed that the energy storage is completely charged at initial time. We have developed the formulation in such a way that it is possible to add any additional constraints or parameters to the optimization model.

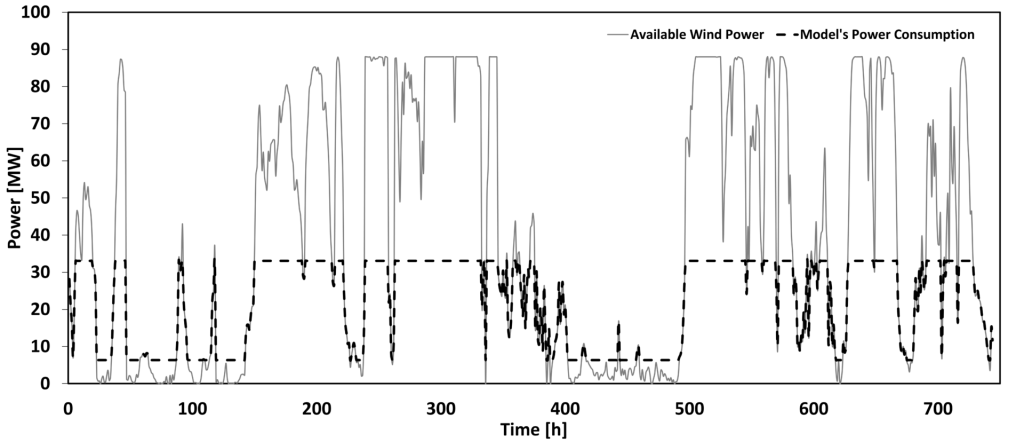

For the first method, power consumption by the processing facility fluctuated according to the amount of wind power available, shown in Figure 2.

Figure 2. The model’s power consumption time series data together with the available wind power.

Seeking Alternatives with Stability and High-Power Output

While theoretically it is possible to reduce production to adapt to wind power constraints, such a sudden change from maximal to minimal power may not be technologically feasible. It usually takes some time for the processing system to adapt to new operating conditions and settings. Very often the wind power was either higher or lower than the required processing power. Therefore, a stable and constant power supply for the processing system needs to be ensured through an auxiliary system (energy storage).

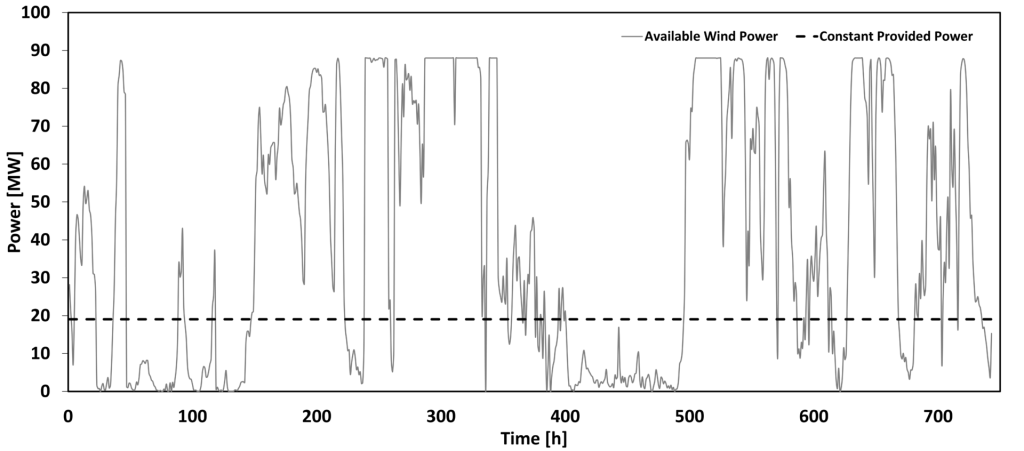

Figure 3. Constant power supply from wind power and energy storage methods.

Figure 3 shows that by utilizing energy storage methods, wind energy can be continuously used for the entire month, providing a reliable and constant source of power for the case study. The amount of energy storage required in this case was of 3,500 MWh. However, it is highly dependent on the energy conversion efficiencies assumed (from wind power to storage, and from storage to processing facilities). Moreover, it allows wind energy to be utilized to its full potential.

Comparing Integration with Gas Turbines

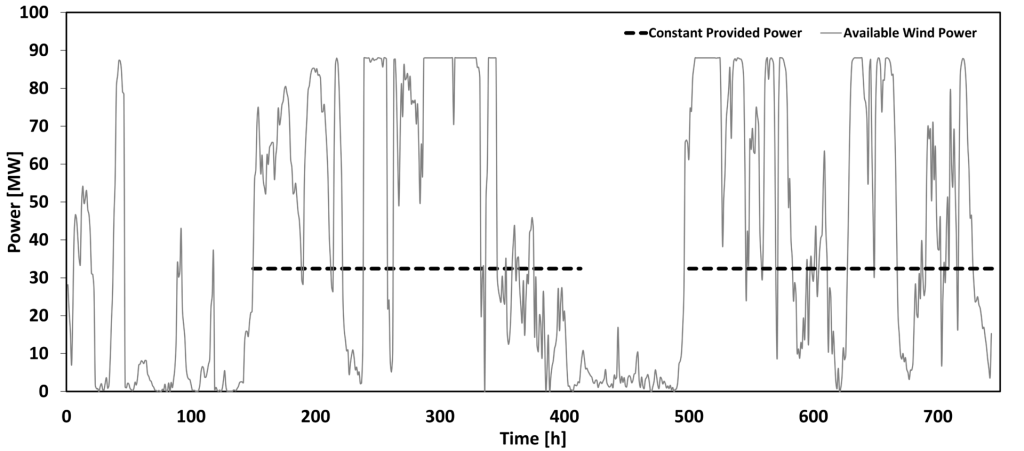

By integrating gas turbines into the previous method, even higher power can be provided with a lower amount of energy storage, as shown in Figure 4. The required storage capacity required for this case was of 1,800 MWh.

Figure 4. Constant power supply from wind power, energy storage and gas turbines.

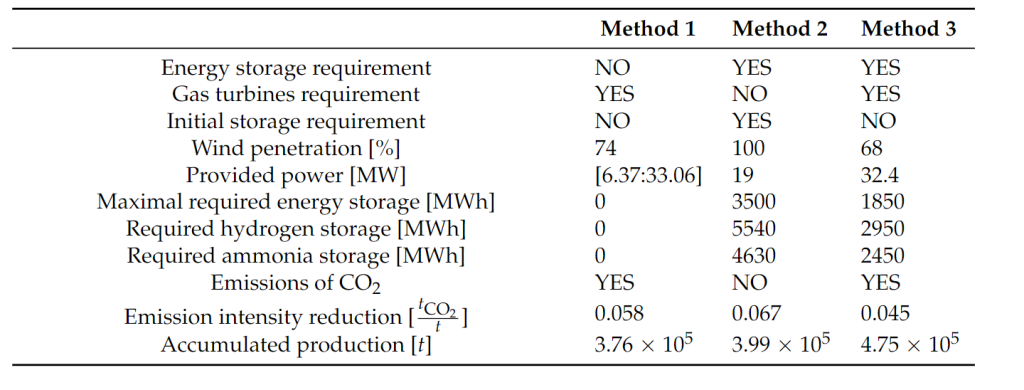

Table 1 summarizes all the assumptions and findings from the different sections of the study. Comparing hydrogen and ammonia storage volumes with conventional oil and gas reservoirs, the required average underground storage volume is not unreasonable for option 2 and 3 although its feasibility should be further investigated. Storage and gas turbines for the system require space and are associated with financial burdens in case they are required.

Table 1. Key results of the methods.

CO2 emissions are reduced by all methods, but at different rates. If the required energy storage capacity is too high, expensive and economically unfeasible, it may be more practical to rely more on gas turbines, even though emitting more CO2.

Other factors should be considered as well, such as the maximum energy storage requirement, the feasibility of providing a gas turbine, the required amount of production, and the maximum emissions permitted. Therefore, a comprehensive feasibility study is necessary to determine the optimum method for a particular case study.

Continuing Research into Offshore Wind Energy Integration

This study is only the beginning of an optimization investigation into offshore wind energy’s potential for powering offshore oil and gas installations. Several operational and economic considerations need to be taken into account when designing a workable technical solution to integrate offshore wind farms with offshore platforms. We invite you to read our paper, and we would also appreciate your comments and suggestions for future work.

Read more from the same author on this topic:

Eyni, L., Stanko, M., Schümann, H., & Qureshi, A.H. (2022). Dynamic Process Modeling of Topside Systems for Evaluating Power Consumption and Possibilities of Using Wind Power. Energies, 15(24), 9482.

Eyni, L., Stanko, M., Schümann, H. (2023). Maintaining constant export oil and gas rates in offshore installations powered by fluctuating wind energy. 42 International Conference on Ocean, Offshore and Arctic Engineering (OMAE).

Comments

No comments yet. Be the first to comment!