Offshore oil and gas activities require large amounts of power, which is traditionally generated with gas turbines running on part of the natural gas produced at the site, since this is a convenient and inexpensive fuel that is normally available in large quantities. Moreover, gas turbines are well fitted to offshore operational requirements and are relatively compact. This aspect is also very advantageous, as space and weight capacity are very limited offshore, and installation of large and heavy equipment is associated with high costs.

Due to their widespread presence, gas turbines are also the main greenhouse gas emission source offshore. This is the case particularly in regions where emission reduction measures, such as limiting non-emergency flaring, have already been implemented. For example, gas turbines fuelled with natural gas are responsible for approximately 85 % of the Norwegian oil and gas sector’s CO2 emissions1. Putting this into context, these emissions are responsible for around 27 % of Norway’s overall emissions2. Therefore, decarbonising offshore operations, especially those from power generation, is necessary for reaching net-zero emissions goals.

Innovative concepts for low carbon offshore solutions

There are several different alternatives to reduce the need of natural gas fired turbines for generating power offshore. However, there is not one solution that fits all installations, and the most appropriate solution will depend on various factors, such as location, remaining lifetime, and type of installation, among others3. It is now becoming clear that there is a need to develop low emission technologies not yet on the market.

In the LowEmission Research Centre, some of these innovative concepts are being developed within the subprojects, each of them dedicated to a group of technologies. A key tool to explore potential synergies among the concepts developed and the resources available within the centre are the Case Studies, where we study potential applications and solutions, also considering the industry’s interests.

One way to fully decarbonise offshore activities is to operate the gas turbines with carbon-free fuels such as hydrogen (H2) or ammonia (NH3). With this alternative, we could still have the operational advantages of gas turbines, but without producing CO2 when generating power and heat. The use of carbon-free fuels is particularly interesting for installations where implementing other effective emissions reduction solutions such as electrification is not possible, for example, due to location.

Ammonia as an alternative fuel

Ammonia is an attractive alternative fuel because it is already transported commercially in a large scale, and shipping technology is mature, so we know that it would be possible to transport ammonia produced onshore to offshore facilities. In addition, ammonia is energy dense, meaning a small volume contains a higher amount of energy compared to other fuels. Ammonia is produced combining three hydrogen (H) atoms and one nitrogen (N) atom. The overall carbon footprint to produce ammonia can be low if the used hydrogen comes either from steam reforming with carbon capture and storage (CCS) or from electrolysis using renewable energy sources.

However, operating gas turbines on ammonia is not completely straightforward. Pure ammonia is not a convenient fuel for gas turbines because it has combustion limitations. Therefore, the fuel should be a blend, and this is studied in the LowEmission Centre. In 2020, SINTEF Energy Research researchers studied the effect of small and large shares of ammonia in methane in the LowEmission Case Study “Partial decarbonization of the Johan Castberg FPSO by ammonia addition in fuel”4. This would only achieve partial decarbonization because the fuel would still contain the carbon in the methane, but it could be a first step.

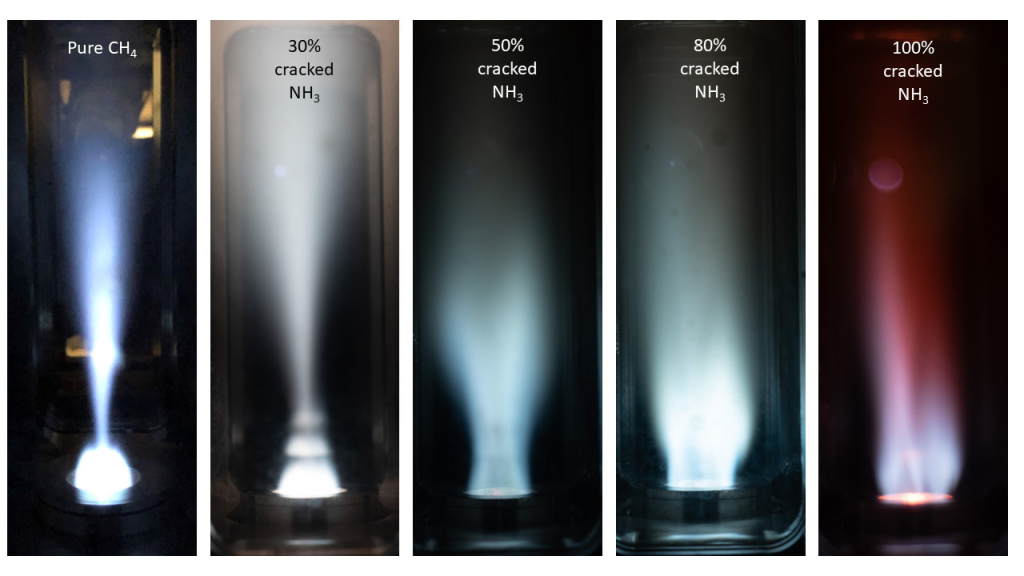

A solution for full decarbonization is to partially decompose (“crack”) the ammonia to produce a blend of nitrogen, hydrogen, and ammonia. This blend would not contain carbon and can be used as gas turbine fuel. Ammonia decomposition is commercial, but the current technology has significant drawbacks for offshore deployment.

Photo: Flame stabilized over a typical gas turbine swirl burner with different fuel composition showing that the more hydrogen in the fuel (ie higher degree of cracking) the more stable the combustion (the flame “occupies” more space closer to the burner). Photos by Mario Ditaranto, SINTEF.

In 2021, SINTEF Energy researchers worked together in the LowEmission Case Study “Reduced-carbon operation of Elgin and Franklin O&G fields”5, proposed by TotalEnergies. These fields are located in the North Sea, between Norway and Scotland, and were an ideal candidate for identifying key dimensional parameters, technological constraints as well as benefits, from carbon-free fuels supply up to their combustion in gas turbines.

LowEmission spin off DECAMMP – Decomposed ammonia for carbon-free power generation

To address the technological constraints identified in the LowEmission Case Study, we proposed the successful KSP spin-off proposal DECAMMP, “Decomposed ammonia for carbon-free power generation”, led by SINTEF Energy Research and starting in 20236. DECAMMP will contribute to overcoming key technical barriers to ammonia decomposition offshore, such as the lack of affordable catalysts that work at the relatively low temperatures. This would enable the surplus energy that is available in the offshore installations to be utilized for the decomposition process.

DECAMMP will also develop the required compact reactor technology, with an integrated reactor model for ammonia decomposition implementing experimental kinetics and flow properties at relevant scale and operating conditions. These advancements will be integrated while developing the concept of an energy-efficient process that considers offshore requirements and operational demands. This will be done considering the ammonia/hydrogen (NH₃/H₂) blends that are optimal for gas turbine operation and overall emissions reduction.

DECAMMP is supported by the LowEmission industrial partners, including operators and gas turbine producers, which will also give important input to assure the relevance and applicability of the results. Johnson Matthey, with a large experience in developing sustainable technology solutions, is also part of the DECAMMP consortium and will provide valuable input. On the research side, DECAMMP will combine the efforts of SINTEF Energy, SINTEF Industry and NTNU.

There is currently a large fleet of operating gas turbines worldwide that could benefit from the results of DECAMMP. The DECAMMP project will enhance Norway’s position as worldwide example for promoting and developing low-carbon offshore solutions. While the concept is aimed at offshore applications, where the impact will be substantial, power generation using ammonia with low-temperature cracking is expected to also play a role in the future onshore integrated low-carbon power system.

Notes:

1 Ministry of Petroleum and Energy and the Norwegian Petroleum Directorate. Emissions to air 2021.

2 Statistics Norway. Emissions to air 2021. Last accessed on 2nd January, 2023.

Comments

No comments yet. Be the first to comment!