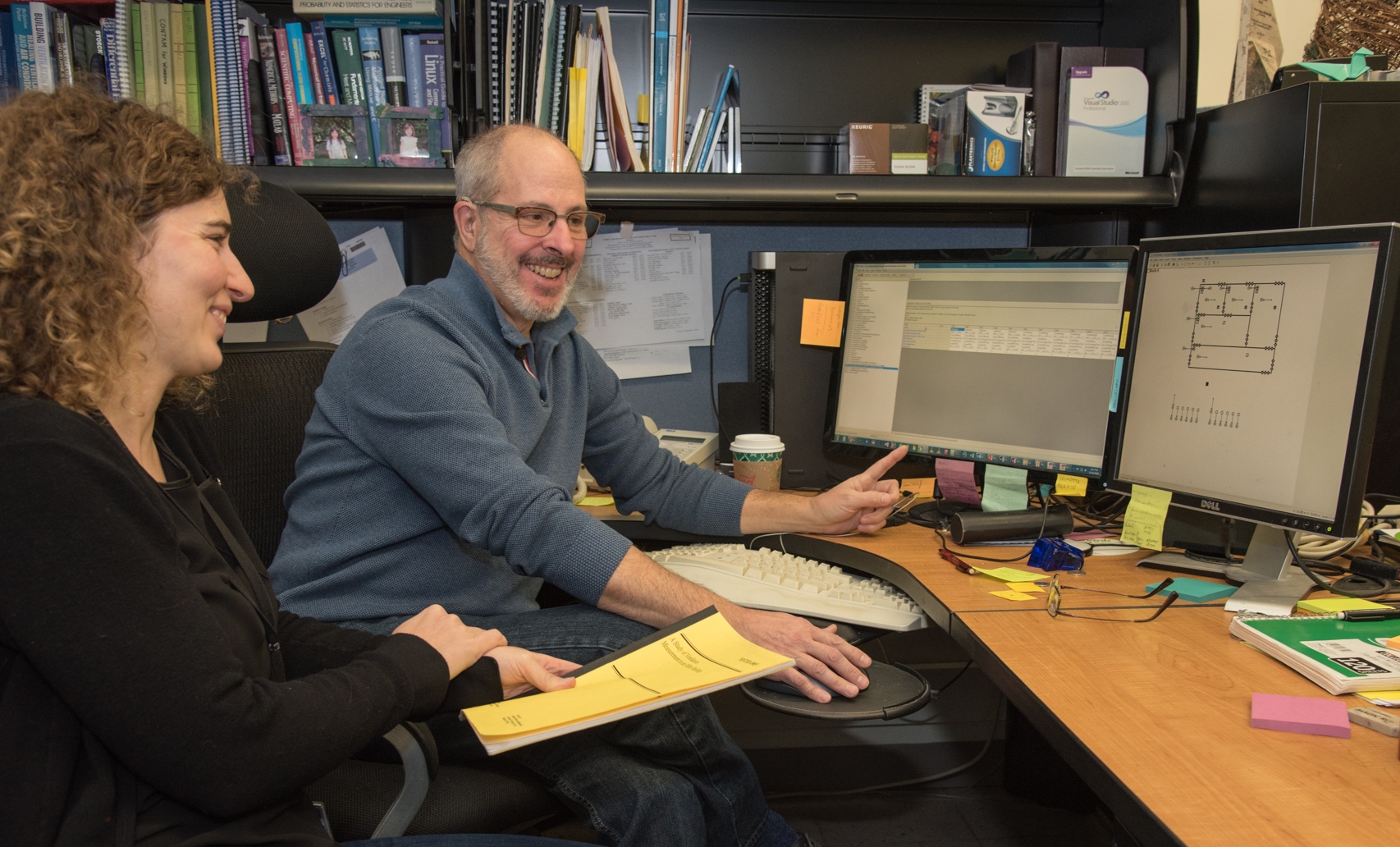

Most of you already know that I am in the middle of a three-month research stay at National

Institute of Standard and Technology (NIST) in Gaithersburg, USA, where I am working with ventilation and heat recovery.

Demand Control Ventilation; is there a reason not to go on with business as usual?

Lately, I have been learning more about the use of demand control ventilation in order to save energy. Demand controlled ventilation means changing the amount of supplied air based on needs for ventilation. Because of this interest, I recently stumbled onto the fact that the controlling of most demand control ventilation systems is based on CO2 and temperature. My colleagues at NIST (National Institute of Standard and Technology), A.K. Persily and S.J. Emmerich, and others, are already working on this topic.

Ventilating based on CO2 and temperatures is per se not at all bad. However, there are other parameters that are very important, and that are seldom looked into when it comes to controlling ventilation. These are the particulate matter (PM) and the volatile organic compounds (VOC). PM and VOC are not necessarily dependent on humans, but more on combustions and emissions from other sources (e.g. furniture).

I have two useful examples:

1. At night, it is common to reduce ventilation to save energy (in office buildings). However, when ventilation is reduced, emissions of organic compounds from furniture are not evacuated. The concentration of terpenes, formaldehyde etc. in the air may increase.

2. Sometimes the outdoor air is polluted with particles from car engines, the combustion of wood, etc. When ventilating with 100% outdoor air, even though the air is passed through filters, we may be introducing the smallest PM indoors. This is similar to what happens when we drive through a tunnel; it suddenly smells bad, and we hit the recirculation button to avoid smelling fumes from the cars’ exhaust.

In both cases, the larger concentration of pollutants may have negative effects on our health. Looking in detail into how we can ventilate taking recirculation into consideration will make a difference!

Connecting programs at NIST

Before I can start my measurements in the ZEB Flexible Laboratory or at the office buildings of ZEN’s partners, I need to understand what happens if we control the ventilation in a different way. To learn more about the effects of ventilation control on energy consumption and the prevalence of bad things in the air, I decided to start with simulations. To ensure that all the partners interested in using my simulations will be able to do so, I decided to use free software. BUT, it was not easy to find a single free simulation program that was doing everything that I wanted.

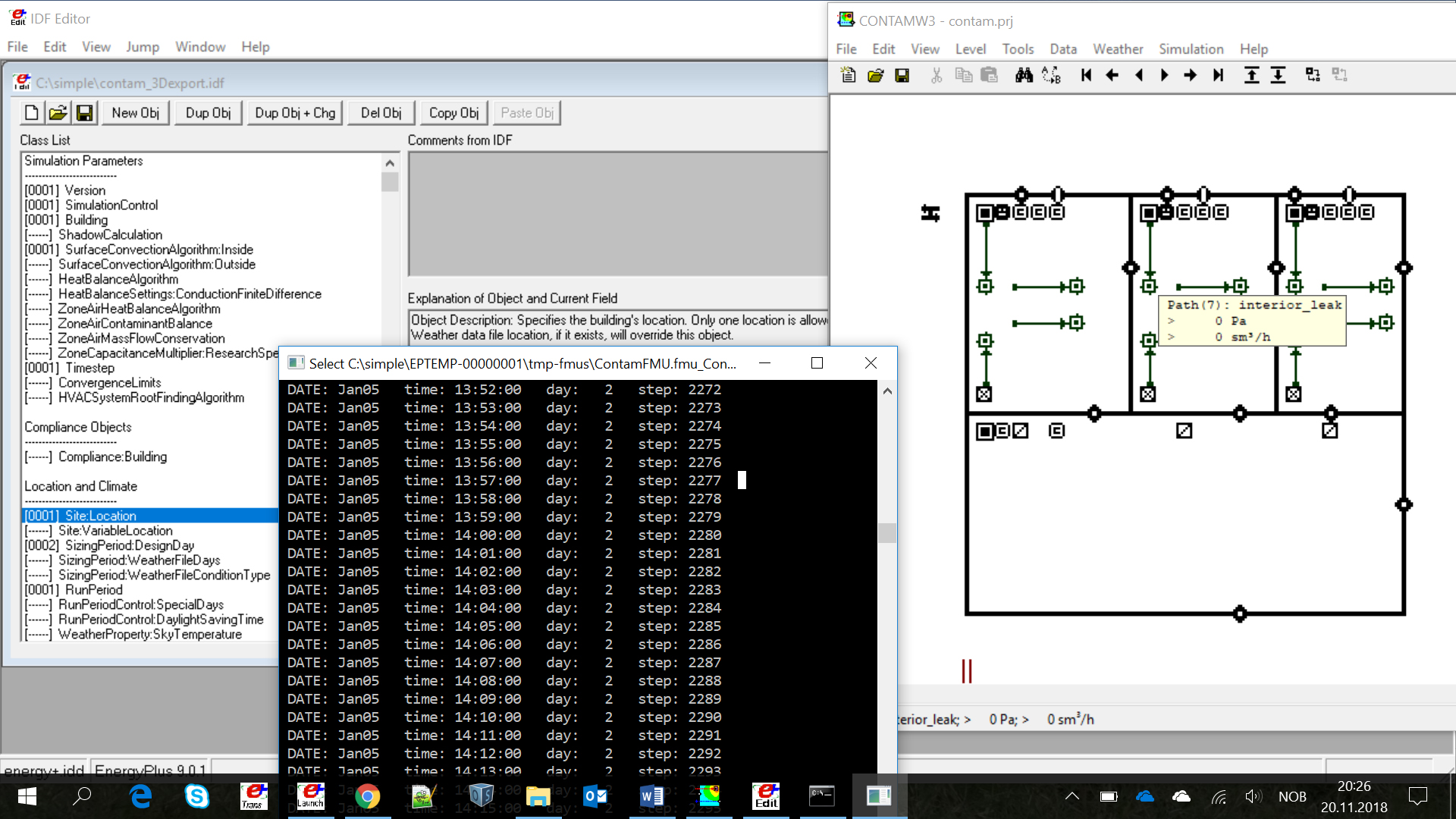

Eventually, I figured out that I needed to co-simulate using CONTAM and Energy Plus. CONTAM simulates contaminants and ventilation controls (CONTAM was developed at NIST). Energy Plus simulates the energy use. Between both programs, there is the Functional Mock-up Interface or FMI, which is a piece of code that makes the programs talk to each other. Most of the work of connecting the two programs has been done at NIST by Stuart W. Dols. That is why, when I started my simulation work, I asked to come and work with him and his team for three months. The ZEN Research Centre, NTNU, SINTEF Building and Infrastructure and NIST accepted and supported my visit.

Using a combination of both programs, I will look at the energy and increase of pollutants (and health effects) of the recirculation of air.

Learning what? Well, mostly I am learning how to make the programs work together. CONTAM is a fabulous tool to calculate the concentration of contamination and to develop ventilation control systems, but it cannot simulate thermal loads. Energy Plus is very powerful, as it can simulate energy use in ventilation, heat recovery, and how the thermal conditions change with different airflows and different heating systems (heat pumps, district heating…), but it is not easy to develop controls. Connecting the two programs will open to more advanced controls. In my case, based on measurements done prior to leaving Norway, I have developed a model of my office’s corridor.

Learning a lot every day!

Finally, being here has helped me building the models enabling the co-simulation, and working with the sensors. Last but not least, I have established a new network with a group of amazing researchers. From them, I have learned a lot, but with them, I have also had lots of fun! Halloween and Thanksgiving have both been a blast, but I will be home in time for Christmas!

Facts about the ZEN Research Centre

– The Research Centre on Zero Emission Neighbourhoods (ZEN) in Smart Cities

The ZEN Research Centre is a centre for environment-friendly energy research. The centre was established in 2017 by the Research Council of Norway. Our goal is to develop solutions for future buildings and neighbourhoods with no greenhouse gas emissions, and thereby contribute to a low carbon society.

The ZEN Research Centre is working closely with municipal and regional governments, private businesses and researchers to plan, develop and operate neighbourhoods without greenhouse gas emissions. The centre has nine pilot projects located around Norway that function as arenas for innovation. The Norwegian University of Science and Technology (NTNU) hosts the centre and leads it together with SINTEF.

0 comments on “Guest researcher diaries”