SINTEF is currently involved in several projects on thermal storage and heat pumps. These two technologies are considered crucial for future industrial and local energy systems, which will be more based on electricity and renewable energy. So far, the focus has largely been on the technologies’ land-based applications. However, at the CruiZE project, we strongly believe that thermal storage and heat pumps are equally relevant for the maritime industry, especially on board cruise ships. Read on to find out more!

The cruise industry creates value in Norway

The cruise industry is important to Norwegian value creation. Before the COVID-19 pandemic, the industry contributed 10 billion Norwegian kroner and 10,000 man-years to the Norwegian economy. In summer 2019, the Norwegian coast received approximately 2,000 cruise calls and 850,000 cruise tourists.

After a 15-month standstill, the cruise ships are starting to resume operations, and the question of their environmental footprint is once again on top of the agenda. The energy demands of cruise ships have traditionally been met by burning fossils fuels, which results in a high carbon footprint per passenger as well as air pollution in major ports worldwide.

Norwegian companies are world leaders in the development of low-emission technology. They are eager to help the cruise industry in their efforts to reduce their environmental impact and combat the associated challenges.

Stricter regulations on cruise ship emissions

Increasingly stringent requirements are being set on emissions from cruise ships at a regional, national, European and global level. For example:

- The International Maritime Organisation (IMO) has agreed to reduce emissions by 50% by 2050.

- From 2026, only zero-emission cruise ships will be allowed to operate in Norwegian fjords featured on UNESCO’s World Heritage Sites list.

- Norwegian ports have established common requirements on cruise ships’ emissions during port stays.

- The EU is proposing that cruise ships must use zero-emission technology in EU ports from 2030.

Cruise ships require a lot of energy

A cruise ship is like a huge, floating hotel. The energy demand of the hotel facilities is approximately equivalent to the propulsion energy demand. The most significant consumption areas include electricity for air conditioning, and heat energy (steam or hot water) for space heating, showers, pools, galleys and laundries. Therefore, even if a ship is docked in port or cruising at a low speed along the fjords, it is still using large amounts of energy. During a 10-hour port stay, an average cruise ship has a power consumption of around 6 MWh, and the heat demand is almost as large. As a comparison, the annual power consumption of an average Norwegian households is 16 MWh. Thus, it is a huge challenge for cruise ships to reach zero emissions.

Read more: Webinar: CruiZE project sharing and discussing how to reach zero emissions

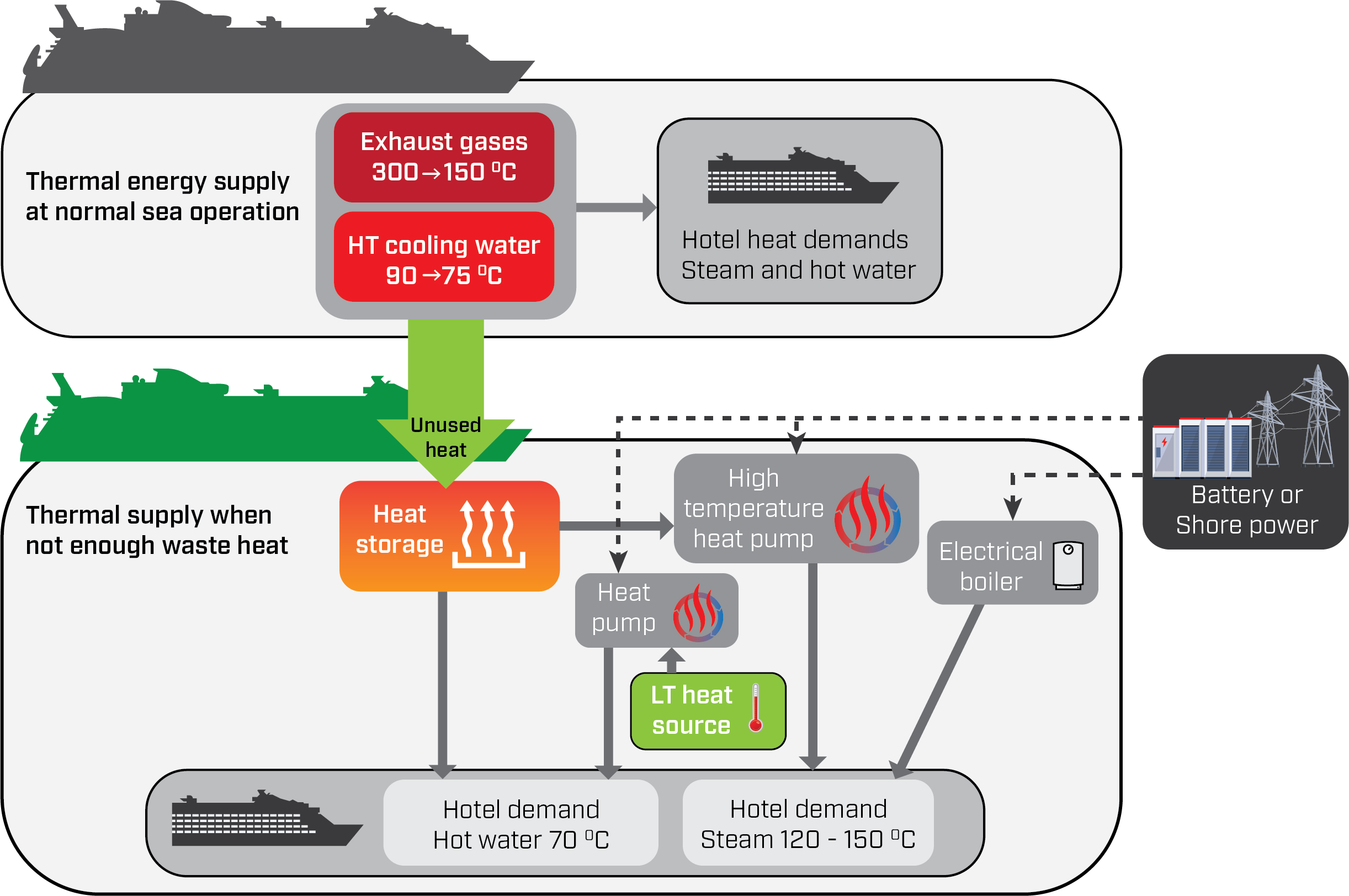

The electricity for both propulsion and hotel facilities is normally produced by fossil fuel engines. The heat demand is preferably met through so-called waste heat recovery, which means that the engines’ hot exhaust gases and cooling water are reused for heating purposes. However, most ships also have an oil-fired boiler that can be used when there is not enough waste heat. This mostly happens when the ship is docked in port, or operating with a zero-emission propulsion system, such as batteries.

Shore power from ports

Many ports are introducing shore power as a means of reducing emissions from ships during their port stay. This simply means that the ship connects to the port’s electrical grid instead of running their fossil fuel engine(s) to produce their own electricity. Switching off the engine reduces both air pollution and noise in the port area, and can also contribute to reducing emissions globally if the grid electricity is based on renewables.

How much can shore power reduce cruise ship emissions?

It is not possible to reduce emissions by 100% with shore power alone. For cruise ships, shore power can help to reduce emissions in port by around 50%. Put simply, this is because the oil-fired boiler is still needed to cover the significant heating demand of the hotel facilities. In fact, the boiler has to produce more heat, as no waste heat is generated when the ship is connected to shore power. This is an important issue that needs to be addressed!

Why not just replace the oil boiler with an electric boiler?

This might seem like the most obvious solution, but it requires additional measures to be taken by both the ship owners and port owners. The ships would have to undergo costly rebuilds, in addition to the ones they are already obliged to carry out in accordance with various regulations. The power grid must be increased to supply approximately double its current peak power capacity, and many ports are already struggling to supply enough shore power due to the electrification of many other sectors.

In this context, replacing the oil-fired boiler with an electrical boiler may actually be counterproductive. If the port cannot supply enough shore power, the ship would have to produce the power on board by using their inefficient fossil fuel engines to operate the electric boiler, which would instead increase emissions and operating costs. Nevertheless, an electric boiler can still be a good solution if it is combined with an energy storage and/or heat pump, which we will discuss later on.

Can ports also supply “shore heat”?

Yes, in some cases this could be an option. In Gothenburg, one particular passenger ship receives “shore heat” by connecting to the district heating network when it is docked. However, since the heating system of most cruise ships is based on steam, district heating water is not always a viable option, unless it is converted into steam using a heat pump either on shore or on board. Again, this would require significant rebuilding as well as a standardisation of connections.

There might be other possibilities for the port to supply heat. The INTERPORT project is examining the economic and technical aspects of different solutions for the port-to-ship supply of various energy types (power, heat, fuel). However, in CruiZE, we are focusing on what can be done on board the ship.

Zero-emission cruising with batteries

There is a lot of ongoing R&D work on solutions for achieving zero emissions for certain periods of time, such when entering Norwegian fjords. Currently, batteries are the most obvious solution. However, if the battery is to also meet the cruise ship’s heating demands, it might be too big for the available space onboard. Another potential zero-emission option is to use hydrogen and ammonia in either engines or fuel cells. But it will take time before this becomes a valid option for large cruise ships, due to their high energy demand, space limitations, and safety concerns.

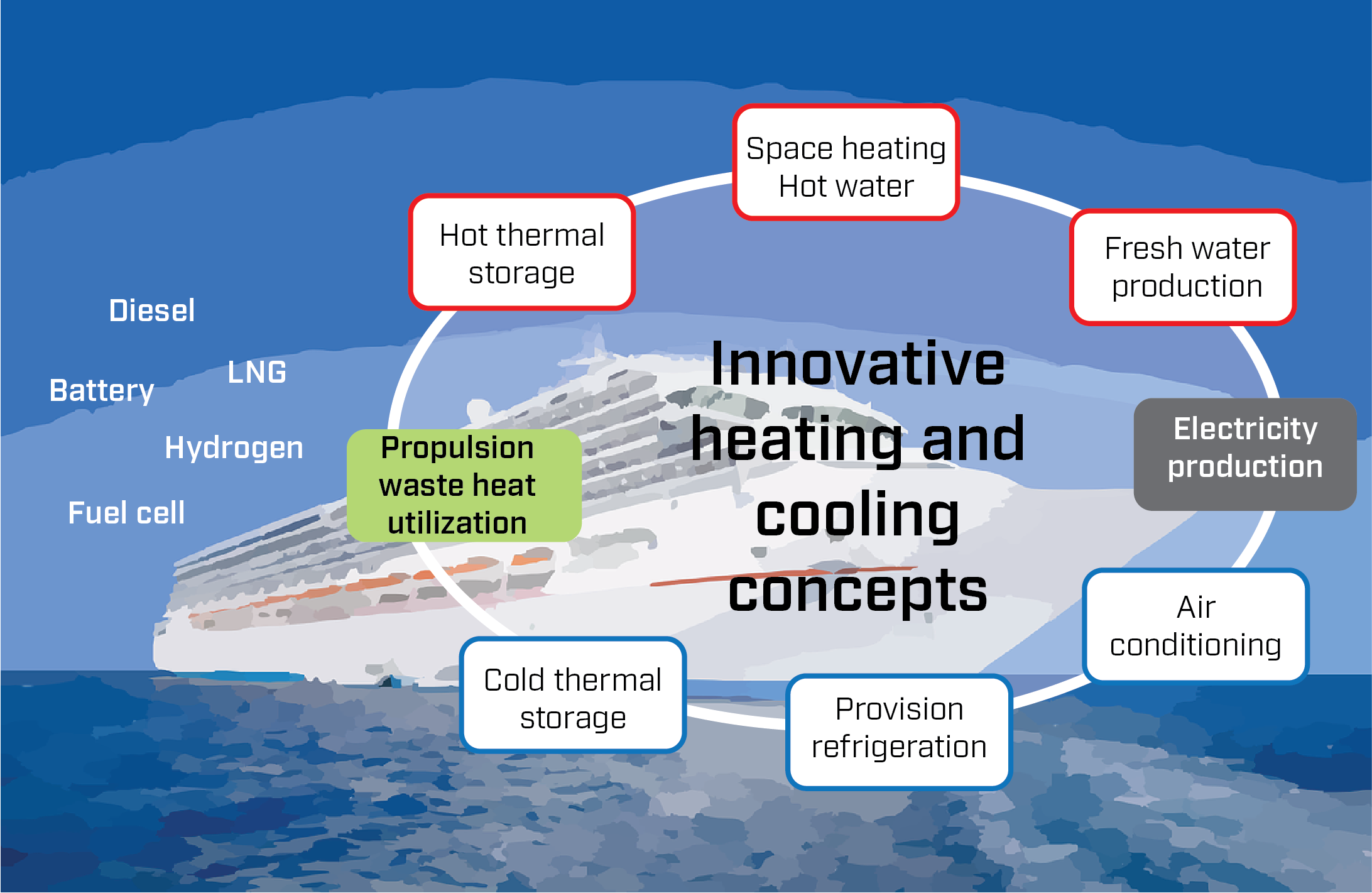

Innovative onboard solutions are required

So, how can new technology enable and facilitate zero-emission power and heat supply, not only in port but also when entering sensitive areas like Norwegian fjords? Cruise ships are expected to, at least partly, rely on combustion engines for many years to come, which means that plenty of waste heat will be generated. This is where thermal storage comes in.

Thermal storage

In general, the purpose of a thermal energy storage is to balance the production and demand of heat by storing the heat (hot water or steam) for later use, like a thermos. When a cruise ship is operating at full speed, more waste heat is generated than is needed on board. Instead of releasing the waste heat into the ambient air or sea water, why not store it and use it when it is needed?

In port, the stored waste heat can be used instead of the oil boiler or to reduce the shore power needed for operating an electric boiler. It can also be used when the cruise ship is running on batteries in the fjords, which means the batteries do not have to also supply electricity to the electric boiler. In other words, the ship can truly operate with zero emissions for a longer period of time. In CruiZE, we use dynamic modelling to find the best way of integrating thermal storage into a cruise ship’s energy system.

Read more: Industrial energy consumption is massive, but thermal storage can boost energy efficiency

The main challenge of thermal storage

The simplest technology for storing the heat is a water tank. However, when space is limited, such as on board a cruise ship, a water tank occupies too much space. By using so-called “phase change materials (PCM)”, the volume of a storage tank can be significantly reduced. There are a number of possible PCMs, all with different properties, opportunities and challenges. In CruiZE, we are evaluating which PCMs that are suitable for marine applications.

Another challenge is that the heat produced and stored might have a lower temperature than the heat demand. This can be solved by “peak heating” with an electric or oil-fired boiler – but the most energy-efficient option is to use heat pump technology.

Heat pumps

The general purpose of a heat pump is to “raise” the heat to a higher temperature, and with the advantage of needing only about one third of the electricity required by an electric boiler to do this. The implementation of heat pumps on cruise ship can serve many different purposes, several of which are being investigated in CruiZE, again through the use of dynamic modelling. Some potential benefits include:

- When the ship is connected to shore power, a heat pump will lower the required shore power capacity by eliminating the need for or supporting the use of an electrical boiler;

- When the ship is operating on batteries, a heat pump will reduce the battery power needed for an electric boiler, thereby enabling the ship to operate with zero emissions for a longer period;

- A heat pump can produce both heating and cooling at the same time, for example cold air conditioning water and hot tap water, thereby reducing the ship’s overall energy demand;

- Heat pumps enable the recovery of waste heat sources at a lower temperature, such as low-temperature cooling water from engines or batteries, or sewage water (grey water);

- Using a heat pump in combination with thermal storage will add flexibility in both design and operation.

For a heat pump to be considered as a zero-emission technology it must be operated using renewable electricity and apply so-called “natural refrigerants”. CO2 is a non-toxic, non-flammable, natural refrigerant that can also enable compact systems. SINTEF and NTNU have largely contributed to the installation of CO2 refrigerants in supermarkets, hotels and fishing vessels around the world. SINTEF has also recently developed the world’s “hottest” industrial heat pump. In CruiZE, we are evaluating how to adapt and apply these technologies to be installed on board cruise ships.

If you would like to join our cruise towards zero emissions, you are very welcome on board!

Comments

Great article with valid points.

Happy to see that solutions are now coming to market, addressing the challenges raised in this article.

Absolutely Brilliant and well written article. Thank you for your time , research and energy on this topic.