In her doctoral work at NTNU, Ingrid Snustad has performed experimental measurements of condensation heat transfer of CO2 on regular metal surfaces and on nanostructured surfaces. The results can point the way towards enhanced methods for CO2 liquefaction.

Because of the drastic impacts that unmitigated climate change would have, the world must rapidly reduce CO2 emissions to net zero and even move to net-negative in the next 25 years. To reach this target we must use all the tools we have available: increasing energy efficiency, deploying more renewable energy, using hydrogen as an energy vector, and last but not least: carbon capture, transport and storage (CCS). Norway is currently implementing the Longship full-scale CCS chain, where CO2 is captured at industrial sites, transported in liquid form by ship to the injection facility, and then injected as supercritical fluid into suitable geological storage.

One key element of this chain is the liquefaction (also called condensation) of CO2, where the gas captured from industrial sites is turned into a liquid with high density before it is shipped away. For other fluids such as steam, people have investigated using nanotechnology to improve the condensation process.

This promising combination of fluid mechanics and nanotechnology has never been studied for CO2. So at the start of this journey, Ingrid Snustad and her colleagues at SINTEF Energy Research teamed up with the NTNU Nanomechanical Lab led by Professor Zhiliang Zhang and Professor Jianying He, and submitted a successful proposal for a Researcher Project under the CLIMIT Programme of the Norwegian Research Council. Thus, the NanoDrop project was born, and Ingrid Snustad was the natural person to be the PhD student in the project.

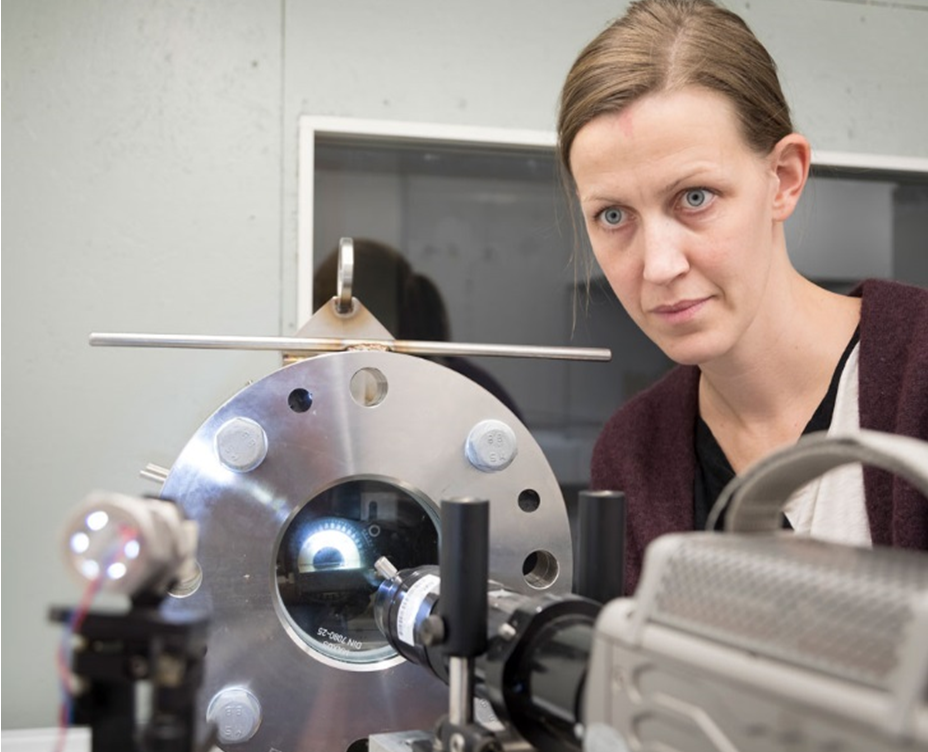

In the beginning of the project, Ingrid took the lead on a review article on enhanced condensation modes, targeting particularly systems that could be applicable for CO2. This work helped guide the further work on fabrication of nanostructured surfaces in the NTNU NanoLab, and the construction of a dedicated experimental setup in the SINTEF Energy Research laboratories for measuring condensation heat transfer on different surface specimens.

Ingrid then spent a lot of time and effort collecting high precision measurements of the condensation heat flux and heat transfer coefficient on different materials.

The final results of Ingrid’s measurements are published in two journal papers, one studying flat surfaces made from different metals, and the other studying nanostructured and hierachically structured surfaces. Ingrid also contributed on a pair of publications on molecular dynamics simulation of CO2 condensation, led by Dr. Jianyang Wu who was a postdoc in the NanoDrop project.

During the PhD defense on June 18, 2021, the first opponent Professor Emeritus Bengt Sundén of Lund University said that the candidate has been successful in building an experimental setup to carry out measurements of filmwise condensation heat transfer, and to obtain interesting results published in highly respected journals. He also emphasized that, as the story often is with experimental work, there are still unresolved questions that require future work.

Dr. Jostein Pettersen of Equinor said that Ingrid’s work has been quite impressive, to work with CO2 which requires high pressures and low temperature, involving small dimensions and temperature differences. He stated that she has produced results of relevance both for refrigeration and CO2 liquefaction, which points the way for future studies to explore how nanotechnology can be used in this field.

Professor Zhiliang Zhang at NTNU was the candidate’s main supervisor, while Jianying He at NTNU, and Amy Brunsvold and Åsmund Ervik at SINTEF Energy Research, were the co-supervisors. Ingrid Snustad is now a Research Scientist at the Department of Gas Technology at SINTEF Energy Research, where she is keen on establishing new projects to continue her work on enhancing condensation heat transfer.

Comments

No comments yet. Be the first to comment!