Using real data to simulate pathways for integrating hydrogen and ammonia as maritime fuels

Meeting our climate goals requires large-scale decarbonization. Hydrogen and ammonia play a promising role in this work, for example, as potential, “green” replacements for conventional fossil fuels in industries like transport and manufacturing. In the maritime industry, switching to green fuels can contribute to cleaner shipping and offshore operations, and, subsequently, achieving the ambitious climate targets set by the International Maritime Organization (IMO).

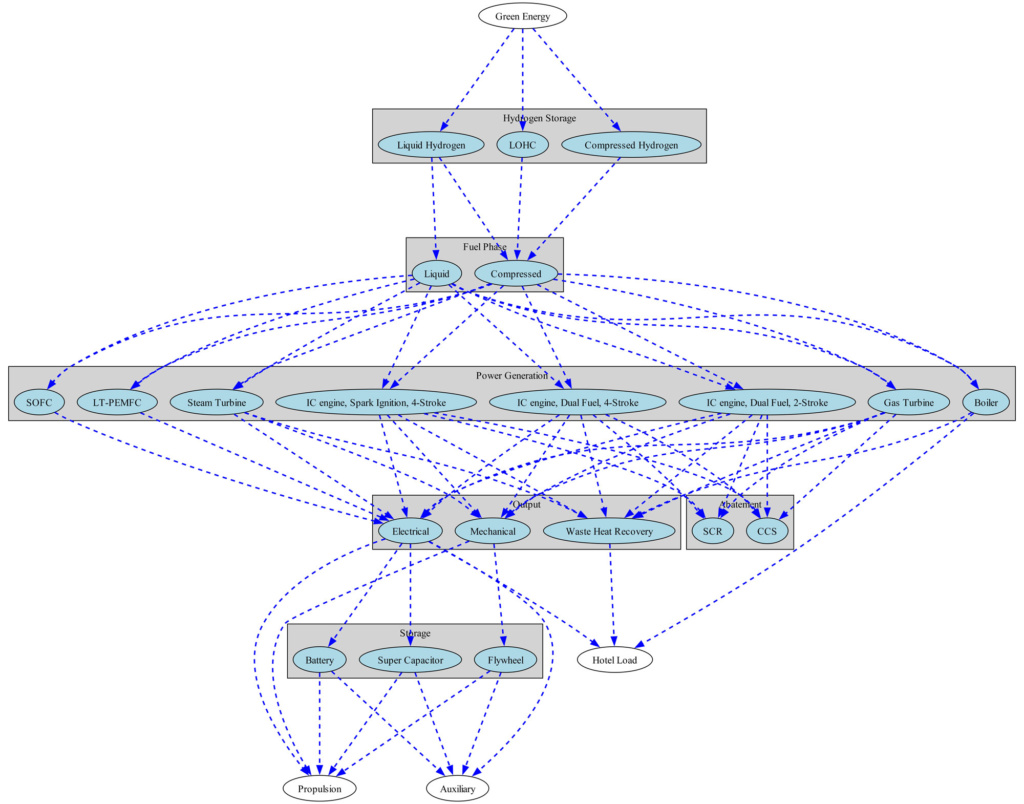

Integrating hydrogen and ammonia as maritime fuels can result in a more complex power system, compared to conventional fuels. As shown in Figure 1, a simple approach could use compressed hydrogen with a combustion engine, which closely resembles conventional ship designs with spark-ignition lean-burn gas engines. However, the system can become more complex with the introduction of hybrid configurations, ammonia crackers, or even abatement systems to manage emissions.

To aid the transition from conventional, fossil-based marine machinery to ones that run on alternative fuels like hydrogen and ammonia, SINTEF Ocean and Bergen Tankers AS have explored a use case, wherein real-time logged data was gathered and logged from the Bergen Viking chemical carrier for a year. This data is being used to simulate different pathways for how the use of hydrogen and ammonia as fuels would impact the ship’s emissions, operational costs and overall efficiency.

At this early stage of technological development, simulations and modeling serve as valuable tools that can provide initial insights into the transition from traditional technologies to new, advanced solutions. One key takeaway from our analysis is that while many pathways appear promising, not all can be implemented immediately due to their low technology readiness level (TRL). Therefore, we focused on pathways that either have a higher TRL or demonstrate strong potential for further development.

This work was performed through HYDROGENi, a Centre for Environment-friendly Energy Research (FME), which focuses on developing hydrogen and ammonia technologies to support Norway’s 2030 and 2050 climate goals.

From conventional to state-of-the-art marine machinery

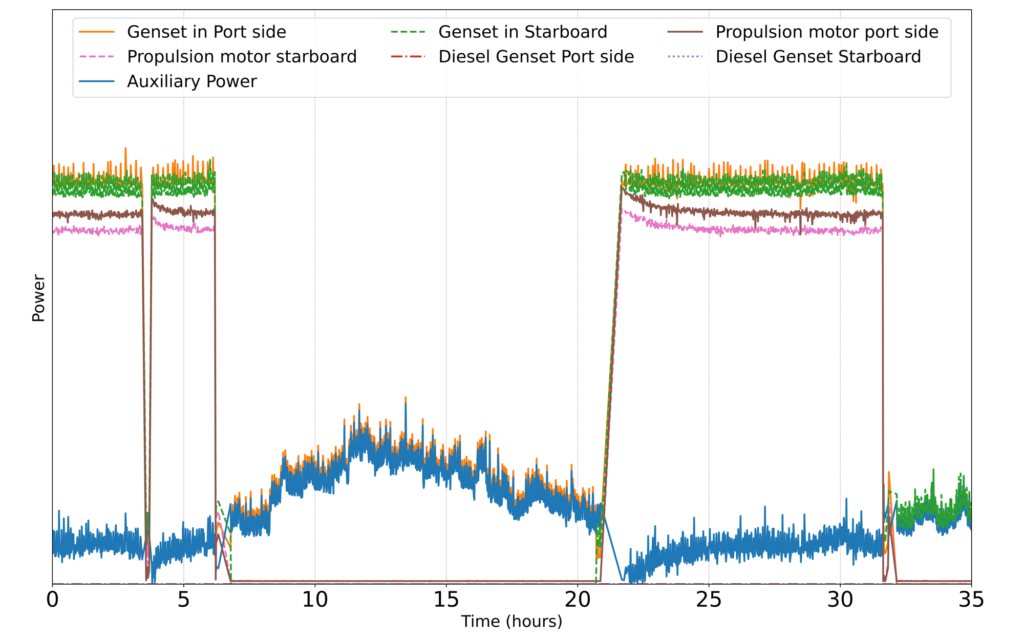

The data collected spans an entire year of operations, from March 2024 to March 2025. Figure 2 shows a snapshot of a typical 35 hours of the ship’s operation. It presents the load distribution of conventional natural gas engines, which are the prime movers, and the diesel generator set (genset), which is an auxiliary mover. As can be seen, the power of the engines is either near full load during transit or at low loads when the vessel is near the ports. At lower loads, the ship speed is close to zero while auxiliary components such as pumps and compressors continue to operate.

Depending on the configuration of the marine machinery, fluctuating loads can significantly impact the ship’s fuel consumption, system efficiency and total emissions. Identifying peak and off-peak loads facilitates a well-designed and optimized hybrid power system, which allows for better integration of hydrogen- and ammonia-based solutions.

While the nominal efficiency of a power converter, e.g engine or fuel cell, may be very high (about 47% for the current power source), the efficiency attained over an operating profile may differ (39% for the current power source). Consequently, both combustion engines and fuel cells may operate at efficiencies different from their nominal values, leading to significant variations in fuel consumption and total emissions. This needs to be taken into account when analyzing the performance of new state-of-the-art systems.

Clean hydrogen and ammonia can significantly reduce greenhouse gas emissions – but careful optimization is needed

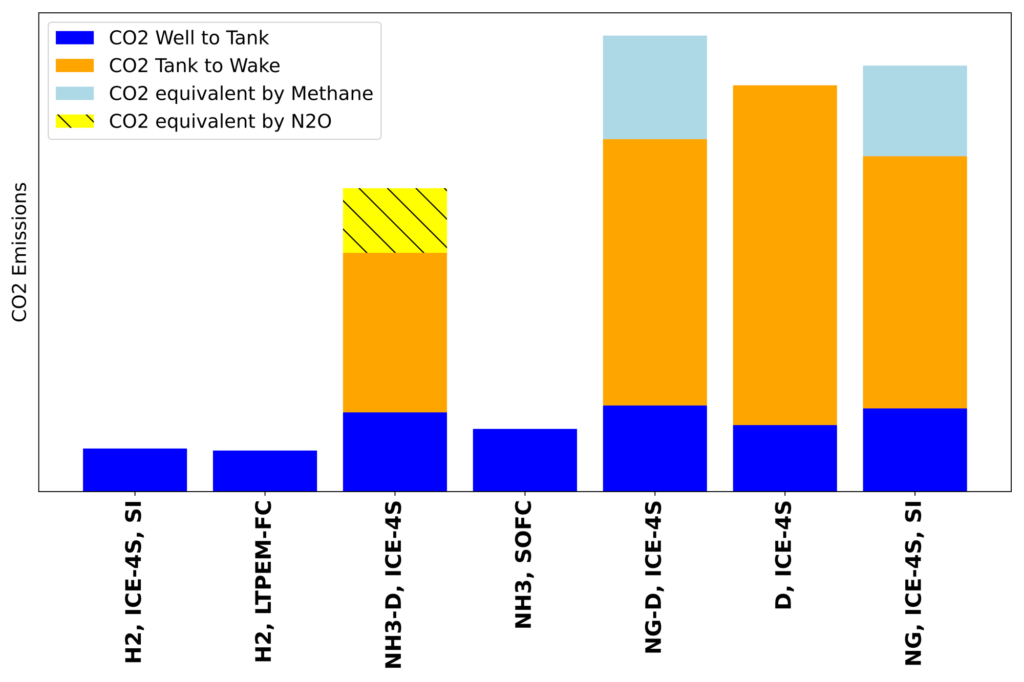

Since our main goal was to identify the potential reduction in equivalent CO₂ emissions by using hydrogen and ammonia, we compared Well-to-Wake (WtW) emissions across different fuel types and power systems.

Figure 3 shows that when hydrogen and ammonia are produced from renewables or with the associated CO₂ emissions captured and permanently stored, the reduction in CO₂ equivalent emissions is significant compared to conventional fuels. This is especially true for fuel cells and hydrogen-based pathways.

However, using ammonia in a combustion engine presents challenges. At lower loads, the high pilot fuel fraction becomes a major source of CO₂ emissions. Additionally, ammonia combustion can lead to substantial nitrous oxide (N₂O) emissions, with a global warming potential 298 times that of CO₂. If the combustion temperature isn’t high enough, these emissions can rise even further.

That said, under well-controlled conditions, ammonia-diesel engines can cut greenhouse gas emissions by 30–45%. But without careful optimization, emissions from this pathway could surpass those of conventional systems. On the other hand, hydrogen spark-ignition engines, along with proton-exchange membrane fuel cells (PEMFC) and solid oxide fuel cells (SOFC), achieve near-zero CO₂ emissions from tank-to-wake. It should be highlighted that the current results do not account for a hybrid power system.

The plan in HYDROGENi is to further develop the model to identify the most efficient system using a hybrid approach and later conduct a total cost of ownership analysis.

The results of these simulations will be presented in more detail at the upcoming CIMAC congress 2025 in Zurich: “Decarbonizing maritime power systems with hydrogen and ammonia integration”.

Comments

No comments yet. Be the first to comment!