Such exposed locations are characterised by stronger currents, higher wind speeds, and larger waves. These conditions present new challenges for fish welfare, structural integrity, and the safety of personnel working at sea.

By harnessing the power of accurate numerical models, we gain the ability to anticipate and mitigate risks before they occur – almost as if we are looking into the future. These models allow us to simulate complex aquaculture operations under a wide range of conditions and scenarios, helping us identify potential failure points, optimize system design, and plan safer procedures.

The challenge with going exposed

By moving production towards exposed waters, the various aquaculture systems will be subjected to increased loads and motions. These increasing environmental loads will require stricter rules and standards to maintain the structural health of the fish cages, mooring lines and vessels typically found at aquaculture sites. Most aquaculture systems consist of flexible and highly nonlinear systems interacting with each other, adding further to the complexity and challenge of going exposed.

Today, working in the aquaculture industry means you are working in the second most risk exposed occupation in Norway. Maintaining or reducing these risks under harsher conditions is a significant challenge. All these challenges highlight the need for predictive tools that can simulate complex interactions under harsh conditions.

Why accurate modelling matters

To reduce risks and increase the safety, reliability and efficiency of operations, we can use accurate numerical models to predict the future. These numerical models should be capable of accurately and efficiently predicting the loads on and motions of the structures during a given aquaculture operation. Such high-fidelity models can act as a ‘playground’ for analysing varying conditions and different concepts, all while avoiding costly and dangerous experimentation at sea.

To make sure the numerical models are accurate, their accuracy should be compared to real-world data. However, obtaining such data is challenging, especially considering the unpredictable nature of exposed marine environments. Therefore, one typically performs scaled-down laboratory experiments where you have full control over the environmental conditions and can accurately measure the loads and responses. There are of course downsides with scaled-down laboratory experiments as well. The main downside lies in so-called scale-effects, where the reduced dimensions can distort physical behaviour, making it harder to replicate real-world dynamics accurately.

Case studies and key insights

To evaluate the accuracy and practical applicability of the state-of-the-art simulation tool SIMA, developed and maintained by SINTEF Ocean, we conducted two complimentary validation studies – one based on full-scale measurements and another using controlled model tests.

Full-scale validation at Tristeinen

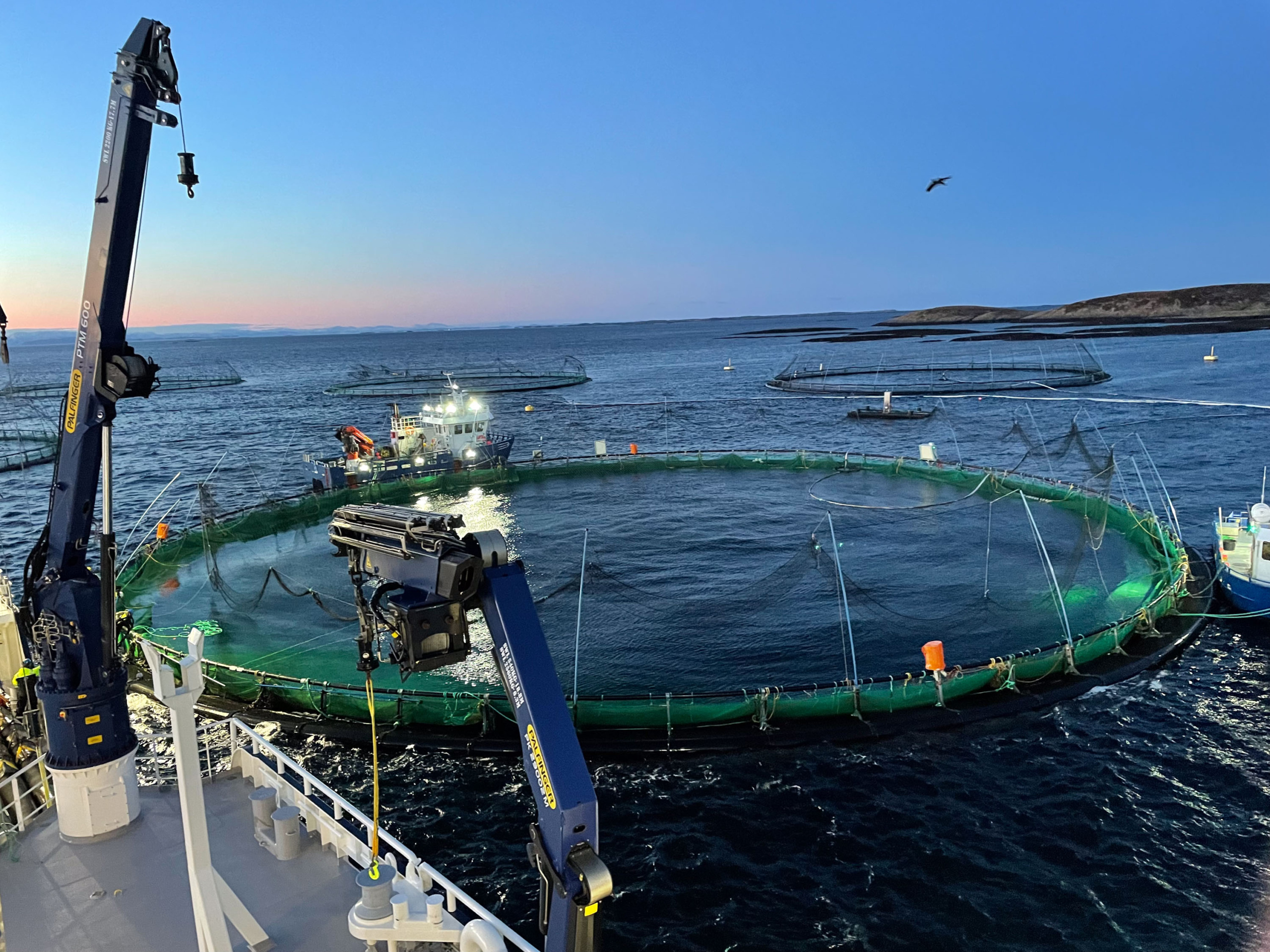

The first study focused on a real-world scenario where a vessel is moored alongside a flexible fish cage, such as during a harvesting operation (Figure 1). Full-scale measurements were carried out at Tristeinen, an exposed aquaculture site located in Frohavet, off the coast of Trøndelag, Norway (Figure 2). These measurements were made possible through SINTEF ACE, a full-scale laboratory facility designed to develop and test new aquaculture technologies.

We developed a numerical model in SIMA to replicate this scenario and compared its output against the full-scale data. The results showed that SIMA can reproduce the overall system behaviour with satisfactory accuracy. However, the study also highlighted key challenges in full-scale validation – most notably, the inability to control environmental conditions and the high computational cost of simulations, which currently limits their use in real-time decision support systems. For a deeper dive into the findings, you can read the full study: Numerical model validation using full-scale data: Well boat moored to fish cage.

Model tests in the ocean basin

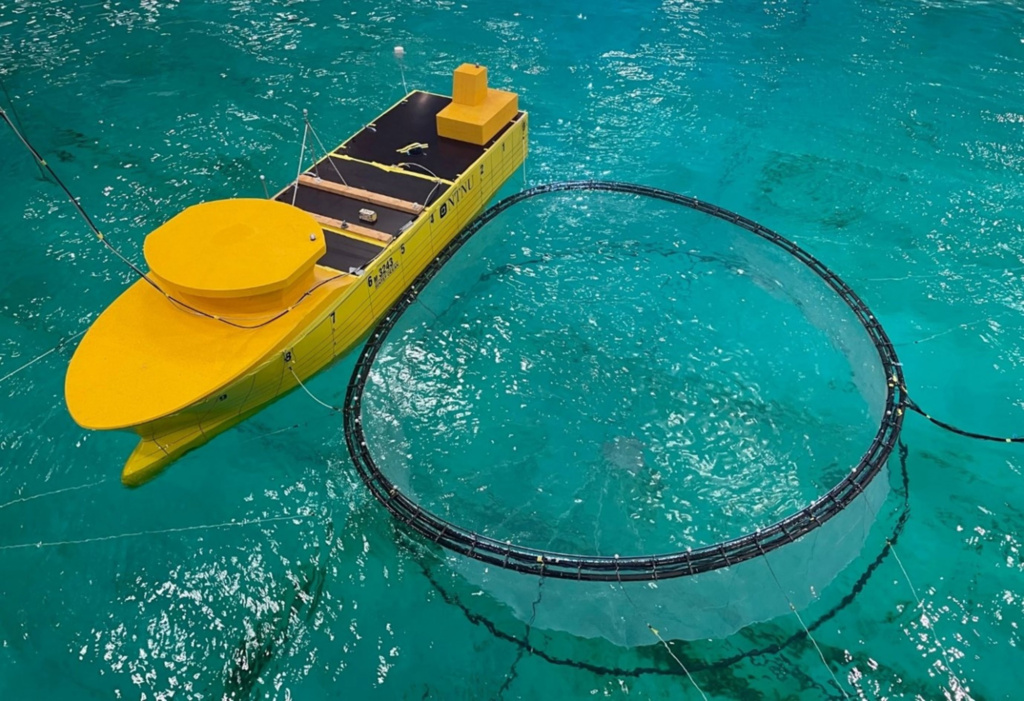

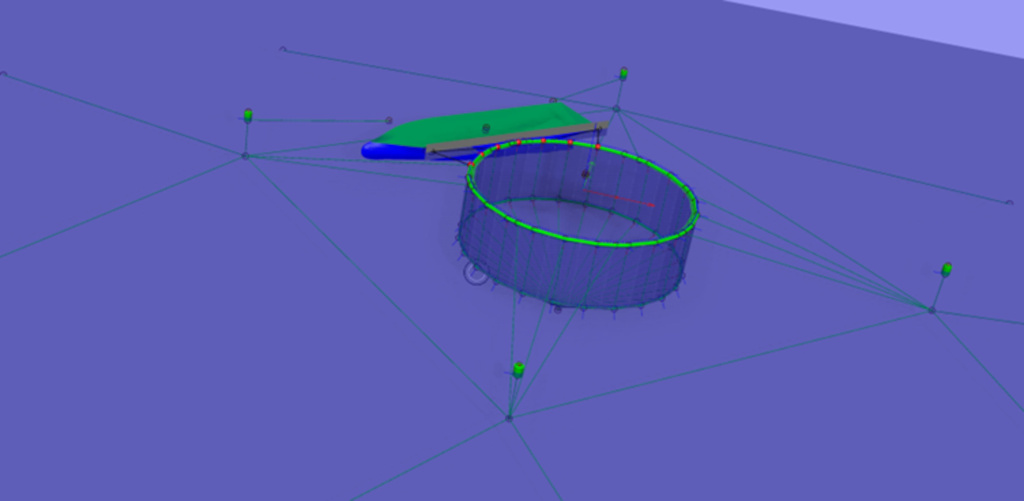

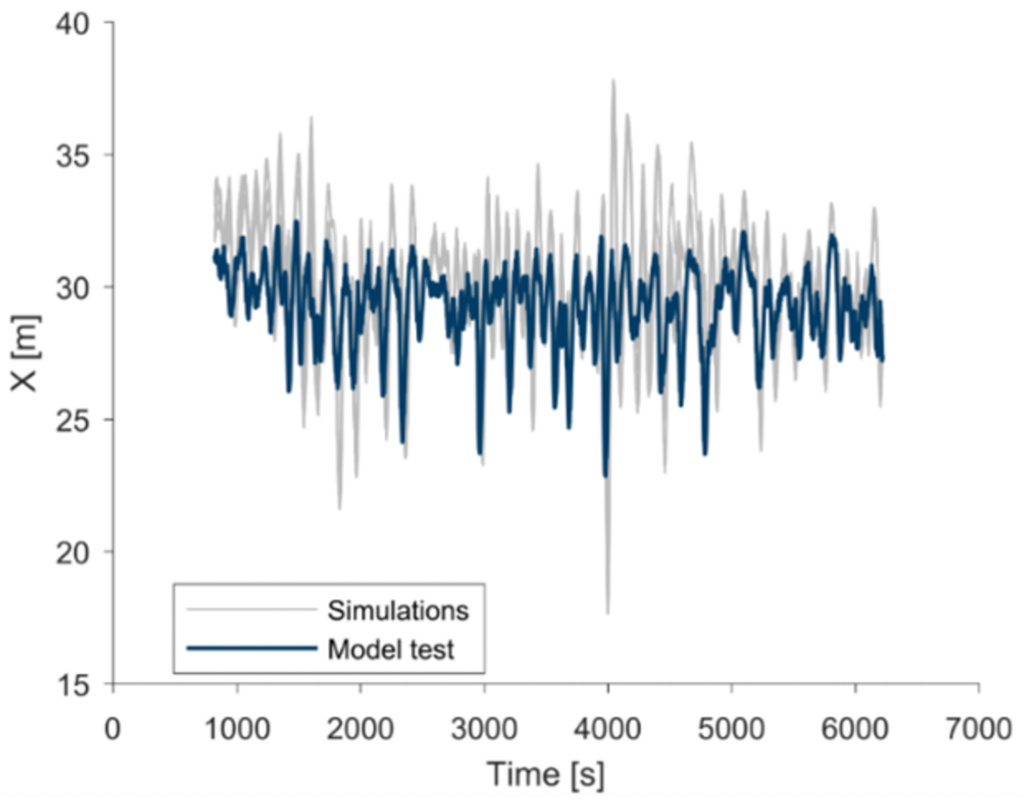

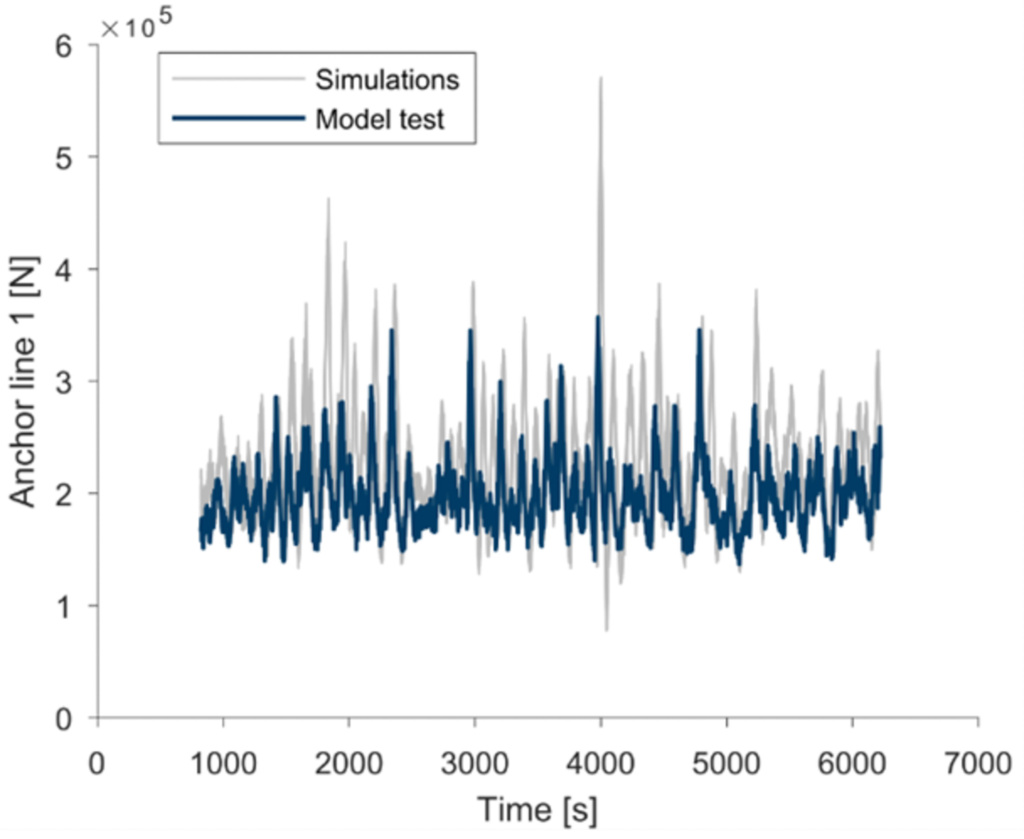

To complement the full-scale study, we conducted model test experiments at the Ocean Basin in Trondheim, marking the first experimental validation of a coupled numerical model of a vessel moored to a fish cage under exposed conditions. The vessel was tested in both beam sea and head sea configuration, subjected to identical environmental conditions (Figure 3 and Figure 4).

Validation was performed by comparing:

- Vessel motions across all six degrees of freedom

- Line forces in anchor, mooring, and bridle lines

- Statistical metrics including mean values, standard deviations, and peak error measures

The results demonstrated strong agreement between the numerical model and physical test data, particularly in mean values and motion phases, confirming SIMA’s capability to capture the system’s dynamic behaviour under exposed conditions. The results are discussed in more detail in our study: Exposed vessel operations in aquaculture: Experimental validation of numerical models.

Future directions

To enhance SIMA’s role in operational planning and risk management, future work should focus on:

- Improving friction modelling

- Accounting for floater deformation effects

- Reducing computational cost

Additionally, integrating machine learning and reduced-order modelling techniques could significantly boost predictive performance and enable real-time simulation and forecasting. This hybrid approach has the potential to transform SIMA into a powerful decision support tool for safer and more efficient exposed aquaculture operations.

Looking ahead: Smarter and safer aquaculture operations

As the industry continues to push towards more exposed waters, the role of accurate numerical simulations will only grow in importance. Future developments may include real-time model integration with sensor data, enabling dynamic decision support systems that adapt to changing conditions. This could revolutionize how we monitor, maintain, and operate exposed aquaculture facilities.

Ultimately, smarter and better modelling means safer aquaculture – not just for the structures and systems, but for the people and the ecosystems that depend on them.

Comments

“We can use accurate numerical models to predict the future.”

Patented technology from 2018 “Aquaculture Wind Wave Energy”, AWWE, and 4Wind1Wave and AWWHybrid are all hybrids in the same category as AquaWind in Spain.

BWIdeol is similar technology, trying to get cheep energy from float wind.

AWWHybrid shows LCOE at € 0,04/kWh and could be a candidate for “numerical models” in the article.