Plasma technology has been proposed as a way to achieve this, and we have studied the feasibility of the concept from physical, chemical and economical points of view.

Dealing with CO2 emissions from industry

The global scientific consensus is that man-made climate change is driven primarily by the release of carbon dioxide (CO2) into the atmosphere. There is a concerted, worldwide effort to improve the energy efficiency in industrial processes and develop “green” alternatives to fossil fuels. For some industries, however, CO2 emissions might be inevitable outcomes of the production processes and chemistry of the raw materials and products (e.g. metal and concrete production). As well, transportation still relies on liquid fuels (e.g. aviation), which also causes CO2 emissions.

The industrial production of synthetic, liquid fuels relies to great extent on the classical Fischer-Tropsch process, where syngas, a mixture of carbon monoxide (CO) and hydrogen (H2), is converted into liquid hydrocarbons that can be used as fuel. Syngas can be produced from e.g. coal, natural gas, or waste, and the Fischer-Tropsch process thus offers an alternative to fossil-based fuels.

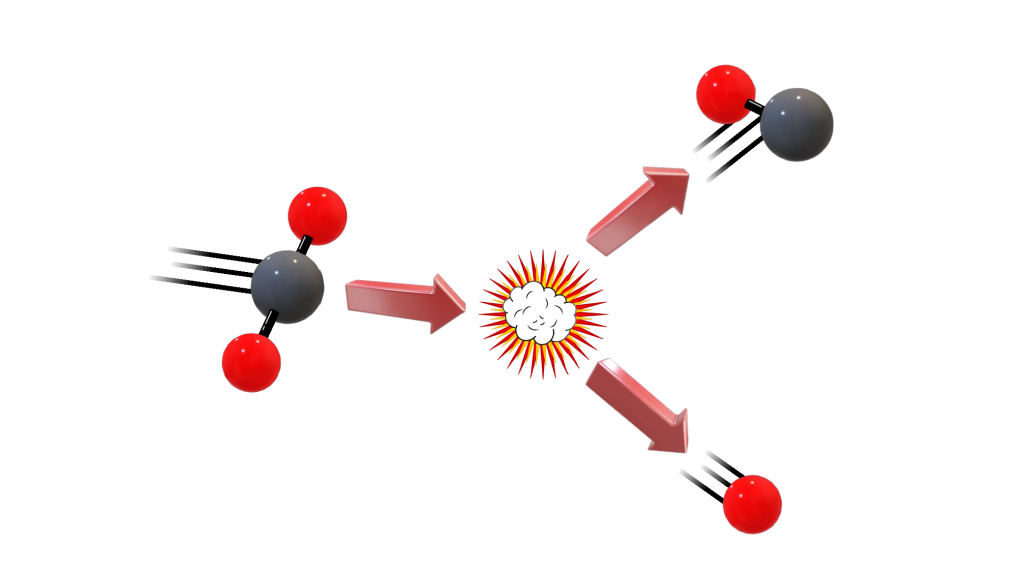

Splitting the CO2 molecule

The CO2 molecule can be seen as a marriage between one CO molecule and one oxygen atom (O). Although they are happily married and their relationship can tolerate a lot of tension, stress, vibrations, and friction, the O-CO bond can be broken – this is known as CO2 dissociation or conversion.

Although CO and O together are perceived as a passive and unattractive couple, they are social and amiable as individuals. So, whereas CO2 is a problem, CO and O are useful chemical building blocks in many industrial products. Thus, it has been proposed to start splitting apart CO2 molecules at industrial scale, to exploit the opportunity of eliminating a major problem at the same time as creating valuable chemicals.

Clean energy must be used in the process

The main challenge with this idea is that a lot of energy is required to create sufficient tension in the O-CO bond, and we need to be careful how this energy is obtained and utilized. Using “dirty” energy (e.g. electricity from the combustion of coal) will emit more CO2 than is converted, so “clean” energy (e.g. electricity from renewable sources) is required to ensure net reduction in CO2 emissions. Additionally, energy is costly, so the energy consumption must be minimized while the value of the produced gas is maximized, to generate profit.

If successful, however, the concept will allow us to kill two birds with one stone by using clean power and CO2 to produce critical raw materials for e.g. fuel production. The main questions are: 1) Is this technologically doable? and if so, 2) Can this be economically feasible/profitable?

Technical feasibility

One way to provide the necessary tension to break the O-CO bond is to heat the CO2. This is known as equilibrium conversion. Science tells us, however, that the temperature must be increased to dramatic levels before the majority of CO2 molecules decide to separate. For example, at 5000 °C most of the CO2 will have separated, but not all. Moreover, it is known that CO and O will tend to re-join into CO2 when the temperature goes down. The solution might be to decrease the temperature extremely fast or to physically separate the CO and O before they manage to re-join. There are, however, significant technological and economical challenges related to these proposals.

Plasma is known as the “fourth state of matter” and denotes a gas-like state where the individual atoms and molecules are triggered to facilitate chemical reactions that cannot occur outside the plasma, and to enhance “normal” chemical reactions. This is achieved via an abundance of free electrons that can exchange energy with molecules and atoms.

Plasma, although normally thought of as a somewhat exotic concept on Earth, has become crucial for our modern way of living. In fact, most normal household items have been “touched” by plasma in their manufacturing process. Recently, plasma has also been suggested as a useful way to convert CO2, since the plasma can be designed in ways that can offer non-equilibrium conversion.

The plasma alternative

Plasma therefore provides alternatives to the high-temperature treatment, since the collisions between the constituents of the plasma (in particular CO2 molecules and free electrons) can cause strong, devastating vibrations in the O-CO bond without increasing the temperature significantly. These types of plasmas are known as cold or non-thermal plasmas. Due to certain limitations with this technology, however, it has so far had limited applicability at industrial scale, whereas huge CO2 volumes must be handled to eliminate CO2 emissions at any cement or steel plant.

SINTEF has investigated the use of so-called thermal plasmas to induce the breakage of the O-CO bond. More specifically, we studied thermal plasmas created by passing electricity through the CO2 gas (like lightening) – an electric arc. The benefit is that thermal plasmas can utilize “clean” energy directly from the power grid.

They also have wide applicability at industrial scale, for example in gasifiers, which are used for incineration of waste and as key components in many chemical processing plants (e.g. in the production of syngas). Thermal plasmas come at the cost of very high gas temperatures, but they do, however, provide the same vibrational excitations of the O-CO bond as the non-thermal plasmas. Hence, thermal plasmas can combine equilibrium conversion with non-equilibrium conversion.

Economic viability of plasma

Mathematical models were used to estimate the temperature of the gas and the extent of CO2 conversion when CO2 flows through an electric arc alone or together with additives such as hydrogen or water. The calculations showed that non-equilibrium conversion was indeed possible, and that a very high conversion efficiency could be achieved. However, the estimated relative electricity cost for driving the electric arc was high. Profitability will certainly require efficient handling of the produced gas, to maximize its market value, and efficient heat recovery from the high-temperature gas, to reduce the net energy expenditure. An increased CO2 tax will contribute positively, and this may be a critical instrument.

Before a final conclusion on the economic viability of this technology can be drawn, the significant challenges related to cooling and refinement of the produced gas mixture must be assessed in more detail. In addition, techno-economical assessment of the construction and operation of the infrastructure required to undertake the proposed CO2 capture concept must be done.

Project Facts:

The project was funded by Oslofjordfondet as a regional qualification project for investigation of feasibility of new technologies for CO2 conversion. The project started in 2017 and was finished in 2018.

The project team consisted of project manager Sverre Gullikstad Johnsen, Richard Heyn, Stefan Andersson and Balram Panjwani. All from SINTEF.

Comments

No comments yet. Be the first to comment!