Even though Norway has the goal to decouple economic growth and waste production, the increase in waste generated every year has still to stop. A person living in Norway produced on average almost 750kg of household waste in 2017 [1], which is an increase of about 65% from 1995 [2].

However, thanks to different measures and regulations, the environmental impact related to waste management has been mitigated over the years.

As part of the solution, in some European countries like Norway, the landfilling of (biologically) degradable waste is banned by law. Instead, waste that cannot be (material) recycled needs to be incinerated in modern Waste-to-Energy (WtE) plants, to minimize its volume, weight and pollution, but also to produce energy efficiently, following the EU directive on waste management hierarchy [3], see the figure.

![Waste management hierarchy according to EU Directive 2008/98/EC on waste management [3].](https://blogg.sintef.no/wp-content/uploads/2019/08/wte-blogg-august-2019.jpg)

Waste-to-energy (WtE) plants are no new technology. They have been used for many years and over the years have become more and more efficient, both in terms of energy production but also in terms of lower emissions.

However, there is still room for improvements.

The main challenge is due to the nature of waste (usually referred to as MSW, Municipal Solid Waste) as a fuel: an inhomogeneous mixture difficult to characterize that changes continuously, in a way that we cannot predict.

Since the fuel is so inhomogeneous, it is quite challenging to get a constant energy output from WtE plants.

As in any other kind of energy-producing plant, we want to keep the energy (heat and/or power) production maximal and stable. However, due to the inhomogeneous fuel, we get big fluctuations in the energy output. In addition, we also have big fluctuations in the temperature of the furnace where incineration takes place. Excessive temperatures cause many problems, like corrosion and wear and tear. Therefore, it is important to keep temperature under control. At the same time, the temperature must be kept above a certain level to fulfill the current regulation.

At SINTEF, we focus on finding operation strategies that can give us better control on WtE.

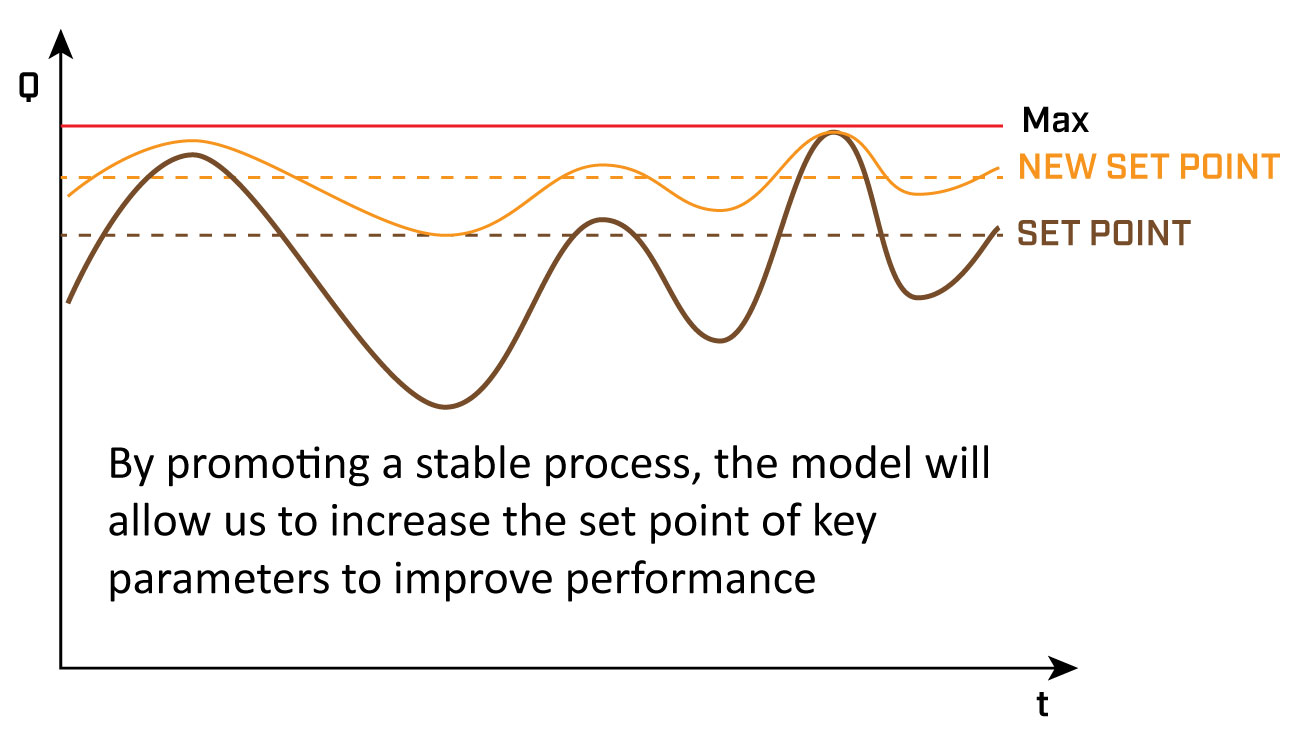

If we manage to reduce fluctuations, we can then optimize the operation by, for example, increasing waste throughput, and at the same time increase energy production, reduce corrosion, and reduce emissions. See the following figure for a quick visualization of an example of improved operation.

Our approach is to try to exploit the real process data that are being collected during plant operation today in a better way, using advanced R&D methods such as dynamic modelling and data analysis.

A typical WtE plant is equipped with hundreds of sensors that monitor different process variables. Measurements are registered up to several times per second, and they might have been collected for as long as decades. This makes not only the volume of data to look at huge, but also its unexploited potential considerable!

However, these large amounts of data are often complex to handle, and due to measurement errors and sensor fouling, the quality of the data can be poor. By using data analysis such as Big Data and Machine Learning, we can handle and process these large data volumes. In this way, we can find patterns and correlations between different aspects in the operation of the plant, that allow us to better understand how different parameters influence energy production.

We also use process data to build and validate a dynamic model of the plant. With this model, we can explore how the plant would behave under new operation strategies, where important process parameters have been modified.

Plant availability (i.e. the number of hours a plant is operating in a year) is also an important aspect. A WtE plant is typically stopped yearly for several weeks to carry out cleaning and maintenance. Moreover, unexpected failures may make additional stops necessary, further increasing operation costs due to plant down-time. Using machine learning algorithms, we can monitor changes in process performance, and we can learn how to predict failures from process history. In this way, we can optimize the scheduling of maintenance activities and eliminate unplanned shutdowns.

Advanced R&D on WtE plants

By combining these advanced R&D approaches and close dialogue and cooperation with our industry partners, we can learn how we can better exploit the capacity of WtE plants, i.e. increase revenues AND reduce maintenance costs. All of this by only improving their operation strategies, which means low investment costs.

Through this project, SINTEF is also representing Norway’s interests in the IEA Bioenergy Task 36, this international Task is aimed at exchange of information on the material and energy valorization of waste in a circular economy, with emphasis on dissemination of information aimed at policy and decision makers. Visit the IEA Bioenergy website for further details about the themes to be investigated in 2019-2021.

[1] http://epp.eurostat.ec.europa.eu

[2] https://www.ssb.no/

[3] http://ec.europa.eu/environment/waste/framework/

In June 2018, the European WtE 2030 consortium, led by SINTEF Energy Research, started a 3-year research project to contribute to improving the performance of existing WtE plants and ensure their relevance in the upcoming circular economy. The main R&D activities, methodology and objectives are summarised in the figure below. Additional R&D activities – enabling WtE to expand beyond its current boundaries – include heat storage, fly ash valorisation and circular economy considerations.

Comments

No comments yet. Be the first to comment!