CO-author: Eirin Lodgaard in SINTEF Manufacturing

Trying to avoid the pitfalls of technology pushes, industrial managers are currently asking: how can we digitalize strategically? In other words: how can we make the technology fit the company’s strategic and operational priorities? In practice, this means integrating the digital technology with a management philosophy based on lean principles.

Lean management remains the fundamental approach to operational excellence within Norwegian industry. The next wave of industrial improvement is widely considered to be driven by the application of digital technologies. Digitalization does not have to replace lean management. Industrial companies should rather try to understand how they can utilize these approaches synergistically.

This theme plays a central role in the research project Lean Digital. The project aims to create new knowledge on digitalization of Norwegian industry based on lean principles as a management approach. This includes the concepts of both digital manufacturing technologies and lean management.

Industrial pioneers and digital transformation

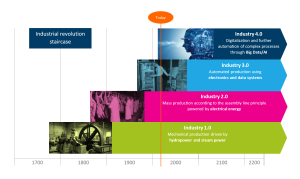

Apart from the research project, SINTEF Manufacturing and SINTEF Digital collaborated on a study on how digital technology is being used in Norwegian industrial companies. The background for this work is the Fourth industrial revolution, in which equipment, objects and users are connected to each other through advanced information and communication technologies that link industrial value chains. This leads to new demands within digitalization when it comes to building competence, as well as adaptability and innovation.

In this study, experiences with digitalization from 33 Norwegian industrial companies have been collected. The CEO/factory manager, technology director/R&D manager, production manager, operators and union representatives have been interviewed, in order to get a broad picture of what is happening within digitalization at the factory level.

The purpose of this study was to highlight and learn from how pioneering Norwegian industrial companies can increase value creation and productivity using digital technology. Based on these results, recommendations are given on what companies should consider in order to strengthen their competitiveness in a market where digital tools are often a prerequisite for success.

The study shows that Norwegian industry is working continuously on its own digitalization. The following main results have been identified:

- Norwegian industry is ready for the digital frontier

- Wide assessment is the basis for implemented changes

- The Fourth industrial revolution and green shift require increased digital expertise

- Organizational development is also needed when companies are to be digitized

- Data sharing opens for new business opportunities

- Integrated digital strategies are necessary

Link to the study “Lær av de beste” (Norwegian)

The study on industrial pioneers and the research project Lean Digital complement each other:

- The study identifies opportunities on how to improve in order to succeed with digital transformation

- The research project contributes with new knowledge which can be used during the implementation of these improvements in Norwegian industry

How does this work in practice? Here are some examples:

Knowledge on organizational development when implementing digital technology

One of the main results of the study is that Norwegian industry needs more knowledge on organizational development when implementing new digital technology.

Several leaders in our study observe that technology project managers strive to relate to the projects as organizational development projects. They believe this is an underrated area, which is important to understand and grasp as opportunity for improvement.

Digitalization is about more than just robotizing and automating production processes. Technologies such as machine learning, and not least artificial intelligence, will make their entry and transform both the way we work and add value. As work tasks move into technology, new work tasks for employees are being created.

In practice, this means that we must think differently about organizations. Roles and distribution of functions between employees are changing. How the individual works and who are working together on the various tasks will also change. Therefore it becomes important that the company analyses its work processes and finds the best possible distribution of work both in and across departments.

Becoming an expert in digitalization

This is one of the main objectives for Lean Digital. More specifically, exploring the evolving relationship between the shop-floor organization with experts within digitalization. Within the field of lean management, extensive involvement of operators is a prerequisite, as it empowers the shop-floor vis-à-vis specialist functions. Thus, we want to figure out how collaboration between the shop floor and the specialist functions is set to evolve in light of digitalization.

Digitalization will transform and change work practices, with more advanced technology requiring more knowledge to operate. Another issue that will be explored is how shop-floor workers and managers may be trained in order to master digital technologies, so that they retain participation in continuous improvement activities which is one of the main principles in lean.

During the project, SINTEF Manufacturing is responsible for the implementation and test demonstrators in industrial settings. In practice, this includes the integration of new knowledge at the industrial partners. Afterwards, an evaluation will be performed and the results will be used when formulating guidelines for further digitalization.

Comments

No comments yet. Be the first to comment!