Summary

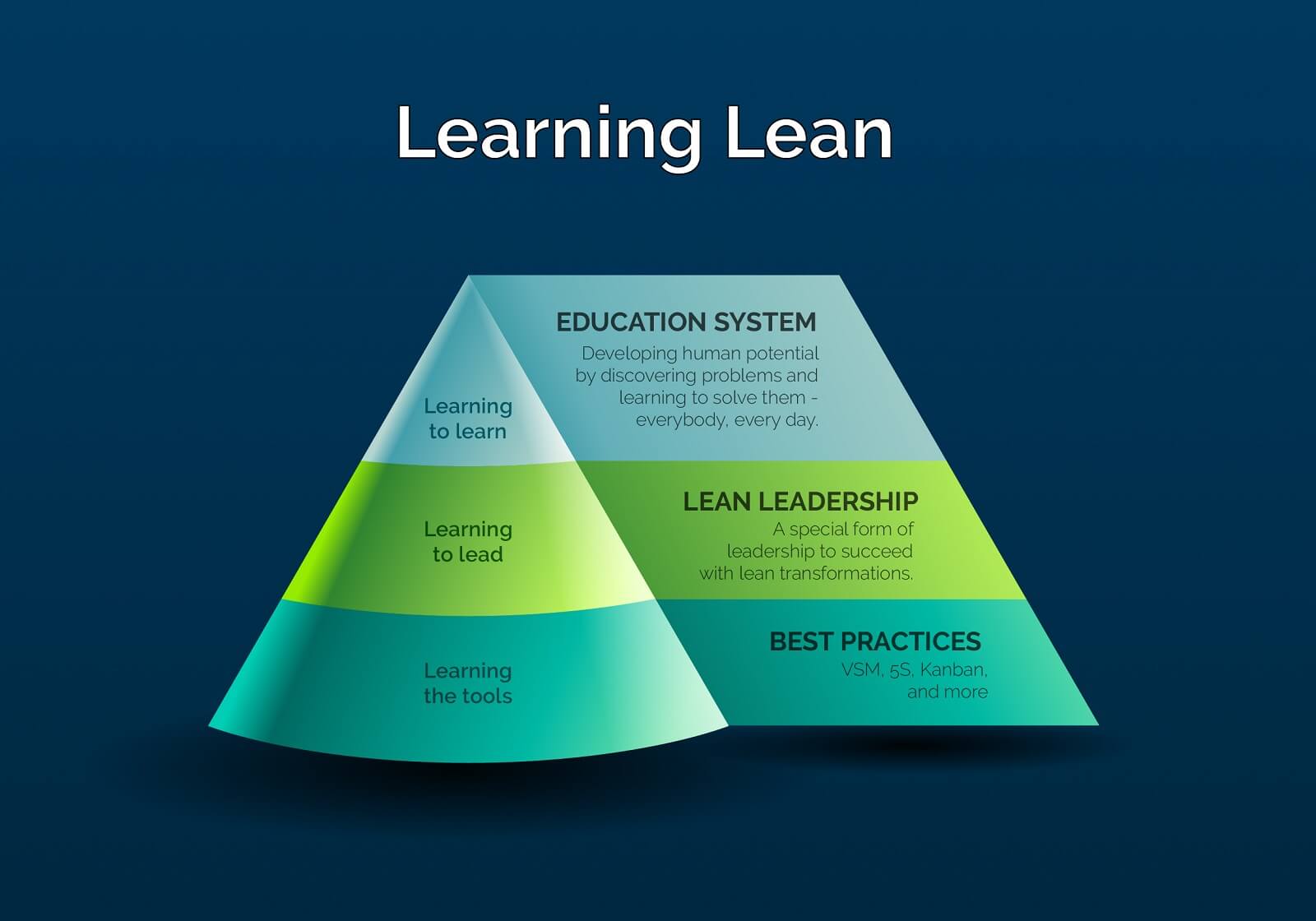

Lean comprises a set of practices that are based on the Toyota Production System (TPS). These have been widely used to improve processes and increase efficiency. However, the scope of lean goes much further than best practices alone. Lean is not a production system. It is an education system that develops human potential through better thinking and practice. Using lean, business leaders can discover new ways of seeing and acting and can learn to adapt to new challenges in a rapidly changing world.

Illustration by Adam Tzur and Daryl Powell.

Illustration by Adam Tzur and Daryl Powell.

Rethinking Lean and Its Potential

Lean has traditionally been considered a production system. It is often reduced to a methodology for process improvement or is seen as a set of tools for eliminating waste. However, the true extent of lean production (or rather lean thinking and practice) spans much further.

I like to say that lean is one of the most misunderstood business concepts of our time. It is funny because it means different things to different people. Inspired by the TPS, lean is now being reinvented as the first truly global approach to collaborative value-creation [1]. It is focused on many aspects, including continual learning, growth and improvement.

My Lean Story: The Three Evolutionary Stages of Lean

There is an ancient Japanese proverb that says, “a frog in a well knows nothing of the ocean“. Its meaning suggests that we should be aware of the limitations of our own knowledge and experiences. Up until some years ago, I was indeed that frog in the well.

You see, my lean story began in Wales in 2005. Fresh out of university with a bachelor’s degree in Motorsport Engineering, I began working for an automotive parts supplier in Llanelli – producing engine components for Ford, Nissan, and of course, Toyota. I quickly became familiar with the various lean tools and techniques, so much so that I went on to take a master’s degree in lean production.

Stage 1: Implementing Best Practices

Over the next few years, I gained expertise in value stream mapping, 5S, kanban, and many other lean best practices. Then, equipped with a full arsenal of tools for operational excellence, I moved to Norway to start a PhD in lean production at the Norwegian University of Science and Technology (NTNU) in Trondheim.

In 2010, things were going great. I had quickly adapted to the Scandinavian tradition of action research and was working with lean implementations in several companies throughout Scandinavia and Europe. Such implementations were based on working through a checklist of best practices, which at that time was typical in industry [2].

Photo: Kongsberg Lean planning. By Daryl Powell.

Stage 2: Lean Leadership

However, I quickly discovered that there was another important element for a successful lean implementation – lean leadership. Of course, today it is a well-known fact that management commitment and involvement is the number one critical success factor for lean implementation [3]. To effectively implement the tools, we need managers to lead the initiatives!

With this new knowledge, my lean research shifted its focus towards engineer-to-order (ETO) manufacturing and led me to Kongsberg Maritime, where I was given the responsibility to design, develop and deploy a corporate lean program throughout the firm’s Subsea division.

In 2015, The KONGSBERG Way was officially launched and systematically rolled out across all the Subsea division’s international operations – in Norway, Spain, Germany, the UK, the US, Canada, and China. The lean program deployment was simple – working with the local management teams, we selected various lean tools and techniques to implement as countermeasures to the hottest local challenges. But behind all the lean best practices and the management system required to support their use, we uncovered a much deeper challenge – to develop the human potential of everyone to create a culture of accelerated, continuous improvement – organization-wide. Suddenly, learning emerged as a core part of lean [4, 5]. This frog had discovered the ocean!

Stage 3: Lean as a Learning System to Develop Human Potential

Lean is not a production system. It is an education system. The name TPS is unfortunate and misleading, as it suggests a collection of production best practices to copy. However, the TPS evolved as the sum of responses that Toyota discovered as it faced specific obstacles. Rather than creating a set of best practices, Toyota engineers crafted a system of learning – which provides a means to discover problems and resolve them. As such, some Toyota veterans prefer to describe TPS as the Thinking People System – a system to teach better thinking – everyone, every day. Lean ultimately requires us to deepen our thinking through hands-on learning, to create more value for our customers. Afterall, Good Thinking, Good Products has indeed been the slogan at Toyota since 1953.

About Daryl Powell

Daryl Powell is Research Manager at SINTEF Manufacturing and Adjunct Professor at NTNU. He has been studying and guiding lean transformations for over 15 years and has both a Master and a PhD in lean. In 2016 he was named amongst The-LMJ.com’s Top 25 lean practitioners in Europe. In 2017 he won a Shingo Research Award as co-editor of The Routledge Companion to Lean Management. He was also awarded a Shingo Publication Award in 2020 as co-author of the Lean Enterprise Institute’s bestseller – The Lean Sensei.

References

- Ballé, M., et al., The Lean Sensei. Go. See. Challenge. 2019, Boston, MA: Lean Enterprise Institute, Inc.

- Shah, R. and P.T. Ward, Lean manufacturing: context, practice bundles, and performance. Journal of Operations Management, 2003. 21(2): p. 129-149.

- Netland, T.H., D.J. Powell, and P. Hines, Demystifying lean leadership. International Journal of Lean Six Sigma, 2019. 11(3): p. 543-554.

- Powell, D.J. and P. Coughlan, Rethinking lean supplier development as a learning system. International Journal of Operations & Production Management, 2020. 40(7/8): p. 921-943.

- Powell, D.J. and P. Coughlan, Corporate Lean Programs: Practical Insights and Implications for Learning and Continuous Improvement. Procedia CIRP, 2020. 93(2020): p. 820-825.

Comments

Very good reflections on a personal learning journey.