No country, no business, no institute can do CCS on their own, James Johnson said on the first day of GHGT-14. And Jérôme Schmitt said that CCS is not a competition, but cooperation. At The Norwegian CCS research Centre (NCCS), we bring nations, businesses and research together to fast-track CCS deployment.

Learn more about CCS

Join our newsletter to stay updated with all the latest research results and news from NCCS: The Norwegian CCS Research Centre.

NCCS is one of the largest CCS R&D efforts worldwide and together with the forerunner, BIGCCS, it has made a difference for the status of CCS today.

Securing cooperation in NCCS

NCCS is a centre of excellence running for 8 years. We started in 2016 and have 6 more years to go. NCCS receives 50% public funding from the Research Council of Norway, the industry contributes with 30% and research partners with 20%. This secures pre-competitive cooperation among the NCCS partners.

NCCS was present at CCS Forum 2018.

Securing industry relevance in NCCS

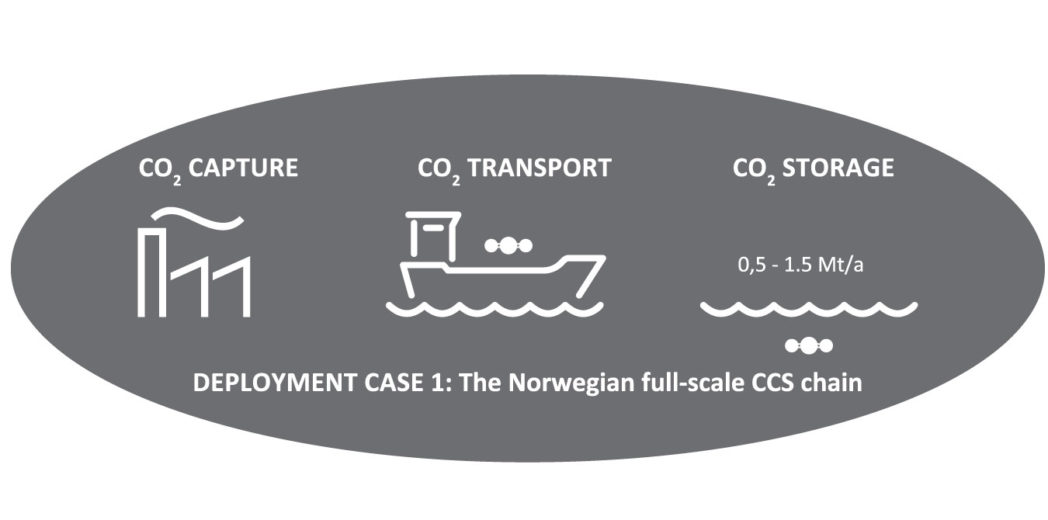

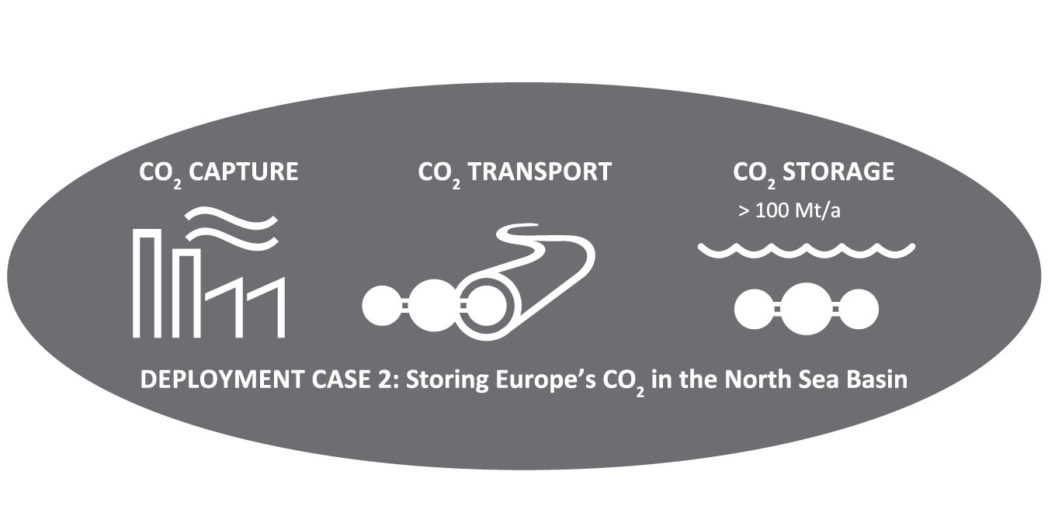

NCCS is organized in two deployment cases. This way, we are relevant for the industry, and we focus on major barriers identified in industrial and pilot projects.

Deployment case 1 is «CCS for Norwegian Industry» which is closely linked to the full-scale CCS project in Norway. It includes CO2 capture from industry sources in the eastern part of Norway, ship transport of CO2 to the western part of Norway, an onshore hub for CO2 storage and injection of 1,5 MT CO2/year through a pipeline into the Johansen formation.

The second deployment case is “Storing Europe’s CO2 in the North Sea basin”. Here CO2 will be captured in large quantities from a variety of sources in Europe and transported by ship and pipeline to Norway. It expands the full-scale project in Norway and the ambition is to store more than 100 Mt/a.

NCCS and the Norwegian full-scale project are linked through deployment case 1, and many industrial players are present in both initiatives. I am convinced that the partnership in the Northern Light project between Equinor, Shell and Total is strengthened by their long-term pre-competitive cooperation in BIGCCS and NCCS.

Other important pieces in the puzzle for NCCS achievements are the policies, the UN development goals, the Paris agreement and the much-mentioned IPCC 6th assessment report.

Don’t miss this blog on the IPCC report by Nils Røkke, EVP of Sustainability in SINTEF.

In Norway, the Government supports CCS through the Norwegian full-scale project, the Test centre at Mongstad (TCM). Further, the long-term funding of CCS research via Climit, Gassnova and support to ECCSEL, a pan-European CCS research infrastructure is very important.

Strong industry engagement in NCCS

The strong industry engagement is a third reason for the importance of our centre. The research tasks in NCCS integrate the contributions to innovation, problem solving and deeper understanding between universities, research institutions and expertise from industry.

Norwegian CCS innovations

One of the success criteria for a centre like NCCS is whether it generates innovations. And it does!

We document innovations from our CCS research portfolio. Now we attempt to put numbers on the potential value of the results.

At GHGT-14 Sigmund Størset presented results from the CCS-part of what is called “the effect study” in Norway, where distinct energy technology research areas document value and potential value of their research. It includes a definition of innovation exceeding a new product entering the marked. The CCS effect study included seven innovations.

AkerSolutions SolvIT

A spin-off from BIGCCS is the Aker Solutions SolvIT- technology. The value of the efficient solvent technology is estimated to 10 € per captured ton of CO2. When a company like Aker Solutions is active in CCS technology development for many years, this adds value, both for Norway, the business and the research community.

Predicting running ductile fractions

A fluid-solid interaction model which predicts running ductile fractions improves the design of CO2-pipelines in a way that can reduce the thickness of a pipeline with 10%. This results in savings, but the most important, it increases the pipeline reliability and optimises operation.

Cementing method saving 20 mill € per well

Thanks to the improved cementing method shortens the operation time for permanent sealing from 60 to 20 days saving 20 million € per well. In addition, correct cemented wells will not leak and hence secure long-term and safe CO2 storage.

Huge potential value

The study shows that even if the Norwegian government through the Norwegian Research council has put a lot of resources into CCS research, the potential value of the results has a significant potential to exceed the input, given that CCS is deployed.

Cooperating for deployment

NCCS brings nations and people together and supports the development of CCS strategies and implementing plans in Norway and the EU. We are also active in cooperation outside EU. Mission innovation and the MoU between the US and Norway on CCS research are great examples.

Last summer the IEAGHG Summer school was arranged by NCCS in Trondheim. Tim Dixon was very satisfied, and the cooperation between NCCS as local contributor and IEAGHG was a success.

Research tasks

The research tasks are key in NCCS. The task families bring vendors, users, PhD-students, professors, and researchers together. This is where the real magic happens.

The research infrastructure ECCSEL is very important for the value and quality of our research.

NCCS has 12 research tasks:

- CO2 value chain and legal aspects

- Solvent technology – environmental issues

- Low emission H2 production

- CO2 separation and conditioning through liquefaction

- Hydrogen fuelled gas turbines

- CO2capture process integration

- CO2 transport

- Fiscal metering and thermodynamics

- Structural derisking

- CO2 storage site containment

- Reservoir management and EOR

- Cost-efficient CO2 monitoring technology

Examples of work done in research tasks

Hydrogen fuelled gas turbines

As GHGT-14 has confirmed, hydrogen is a route to decarbonize the industry and power sector. In NCCS Task 5 we study in detail combustion of hydrogen in gas turbines.

We have access to supercomputers at the Sandia national lab for the direct numerical simulations. High-pressure combustion ECCSEL research facilities permits advanced experiments. Supported by trustful cooperation with Ansaldo, NCCS develops hydrogen fuelled gas turbines.

CO2 transport

This is a real CCS facility. It is a vertical loop going 100 meters into the ground for studying CO2 injection. The data will be used for CO2 injection model development and verification.

Structural derisking

NCCS researchers have worked closely with the Northern light project to study faults which possibly affect potential CO2 storage sites for the Norwegian full-scale project. Elin Skurtveit presented this at GHGT, and this picture shows a detailed Vette fault mapping.

NCCS brings nations, businesses and research together.

Together we contribute to overcome barriers for fast-tracking CCS deployment. We all know it is sorely needed.

NCCS is cooperation.

Learn more about CCS

Join our newsletter to stay updated with all the latest research results and news from NCCS: The Norwegian CCS Research Centre.

Comments

No comments yet. Be the first to comment!